Fuel delivery on a SC'ed engine is essential to avoid detonation. My initial SC'ed fuel delivery system consisted of a single GT fuel pump, 40amp BAP, and stock wiring. I'm making 13lbs of boost and @ WOT my FPDC is about 96%. It's not bad but I felt the need to lower the FPDC and upgrade the wiring at the same time. I used Brian's (Fordnut) delivery system as a template for my design.

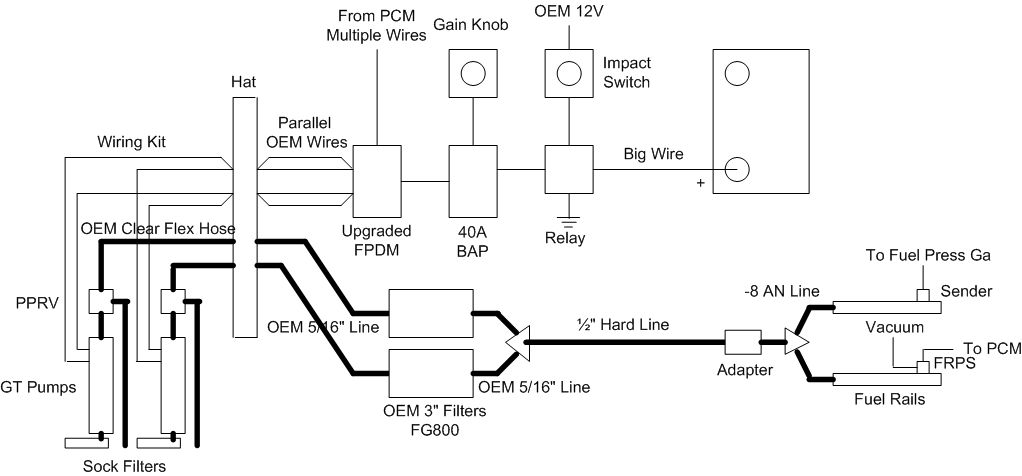

This is Fordnut's fuel system:

I made a few edit's to his design:

-dual FPDM's

-4lbs hobbs switch

-dual wiring to each GT pump

-3 relays (1 for each FPDM and one for the BAP)

-separate 3/8" hard line to the rail (instead of the 1/2")

I started with the wiring and added a new #8AWG primary wire with a 40AMP inline fuse from the power block to the trunk. It hits a 40AMP relay(triggered by the inertia switch) then runs into a 40amp KB BAP, then out to 2 separate 20AMP fuse holders. A second relay feeds GT pump#1/FPDM#1. The 3rd relay feeds GT pump#2/FPDM#2 (the relay can also be triggered on by a WOT signal). Currently I have the relays all on triggered VIA the inertia switch. The system can easily swap over to 4 different configurations

-Single GT pump/FPDM#1 with a BAP on @ WOT

-Single GT pump/FPDM#1 with a second GT pump on @ WOT

-Dual GT pumps/FPDM#1-#2 full time (no WOT trigger)

-Dual GT pumps/FPDM#1-#2 full time and trigger the BAP @ WOT

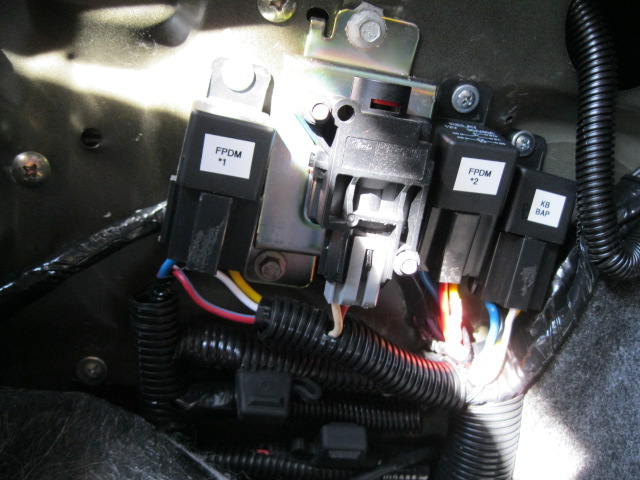

The WOT trigger is a 4lb hobbs switch. Here is a shot of the wiring upgrade. The second FPDM and BAP are wired on the back side of the trunk brace out of site from plain site.

The second FPDM and the 40amp BAP are mounted on the backside of the trunk bracing. Here is a pic of the harness to the new FPDM

The three relays: one for main power on (on/off for the #8awg battery feed) one for FPDM/GT pump #1 and one for FPDM/GT pump #2

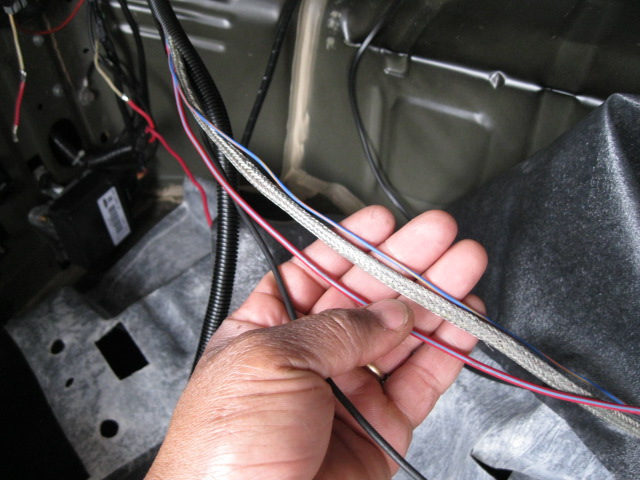

The stock fuel pump +/- out were shielded with a drain so I did the same thing for the new pair of 12awg wires going to the new GT pump.

All the added wiring is wrapped in electrical tape then protected with convolute tubing, finally tywrapped and fastened

I wanted to make sure the factory carpeting went back in place without any humps

The next bridge I crossed was increasing the delivery from the tank to the fuel rails. Having a wrecked Marauder in the back yard was a great help. I removed all the stock fuel lines from the tank to the engine compartment. Cleaned them up a little and installed them. The benefits in using these parts were great. They were free, have the correct bends and connections on each end, and will double my fuel capacity to the engine bay

I made good use of the stock rubber insulators.

Simple SS band clamps and the new line is well supported off the existing 1/2" vapor recovery line

The front hardline dropped right in. The rear one took a little work to figure out. Once I held my head in the right position it dropped right in.

The stock fuel filter has to be relocated up higher to make room for the second bracket. I had to cut the right side of the donor fuel filter bracket so it would fit within this area.

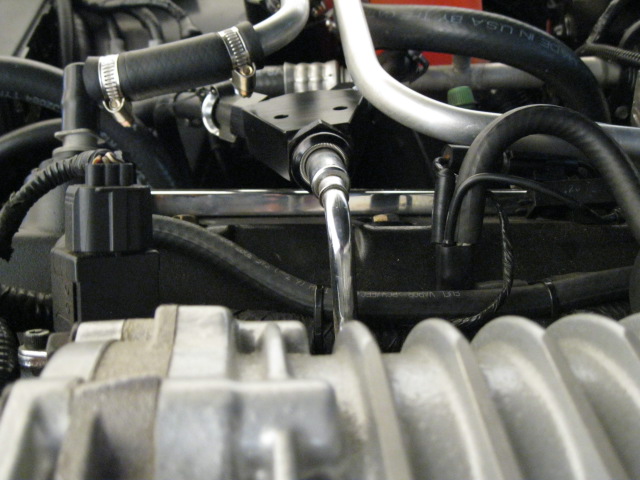

The combined lines run into the engine bay and plug directly into a modified -8AN Y block. This block makes use of the stock quick connect fittings and parallels my dual fuel lines

The SS flex lines at the tank also have an OEM quick connect fitting. I plan on keeping these in tact so I used a donor fuel hat. I cut the stock tip off and flared it to act as a barbed fitting to accept a piece of 3/8" submersible fuel line.

Now the plumbing is done I got started modifying the fuel hat. Here's a pic of the stock hat with a single GT pump

This is Fordnut's fuel system:

I made a few edit's to his design:

-dual FPDM's

-4lbs hobbs switch

-dual wiring to each GT pump

-3 relays (1 for each FPDM and one for the BAP)

-separate 3/8" hard line to the rail (instead of the 1/2")

I started with the wiring and added a new #8AWG primary wire with a 40AMP inline fuse from the power block to the trunk. It hits a 40AMP relay(triggered by the inertia switch) then runs into a 40amp KB BAP, then out to 2 separate 20AMP fuse holders. A second relay feeds GT pump#1/FPDM#1. The 3rd relay feeds GT pump#2/FPDM#2 (the relay can also be triggered on by a WOT signal). Currently I have the relays all on triggered VIA the inertia switch. The system can easily swap over to 4 different configurations

-Single GT pump/FPDM#1 with a BAP on @ WOT

-Single GT pump/FPDM#1 with a second GT pump on @ WOT

-Dual GT pumps/FPDM#1-#2 full time (no WOT trigger)

-Dual GT pumps/FPDM#1-#2 full time and trigger the BAP @ WOT

The WOT trigger is a 4lb hobbs switch. Here is a shot of the wiring upgrade. The second FPDM and BAP are wired on the back side of the trunk brace out of site from plain site.

The second FPDM and the 40amp BAP are mounted on the backside of the trunk bracing. Here is a pic of the harness to the new FPDM

The three relays: one for main power on (on/off for the #8awg battery feed) one for FPDM/GT pump #1 and one for FPDM/GT pump #2

The stock fuel pump +/- out were shielded with a drain so I did the same thing for the new pair of 12awg wires going to the new GT pump.

All the added wiring is wrapped in electrical tape then protected with convolute tubing, finally tywrapped and fastened

I wanted to make sure the factory carpeting went back in place without any humps

The next bridge I crossed was increasing the delivery from the tank to the fuel rails. Having a wrecked Marauder in the back yard was a great help. I removed all the stock fuel lines from the tank to the engine compartment. Cleaned them up a little and installed them. The benefits in using these parts were great. They were free, have the correct bends and connections on each end, and will double my fuel capacity to the engine bay

I made good use of the stock rubber insulators.

Simple SS band clamps and the new line is well supported off the existing 1/2" vapor recovery line

The front hardline dropped right in. The rear one took a little work to figure out. Once I held my head in the right position it dropped right in.

The stock fuel filter has to be relocated up higher to make room for the second bracket. I had to cut the right side of the donor fuel filter bracket so it would fit within this area.

The combined lines run into the engine bay and plug directly into a modified -8AN Y block. This block makes use of the stock quick connect fittings and parallels my dual fuel lines

The SS flex lines at the tank also have an OEM quick connect fitting. I plan on keeping these in tact so I used a donor fuel hat. I cut the stock tip off and flared it to act as a barbed fitting to accept a piece of 3/8" submersible fuel line.

Now the plumbing is done I got started modifying the fuel hat. Here's a pic of the stock hat with a single GT pump

Last edited: