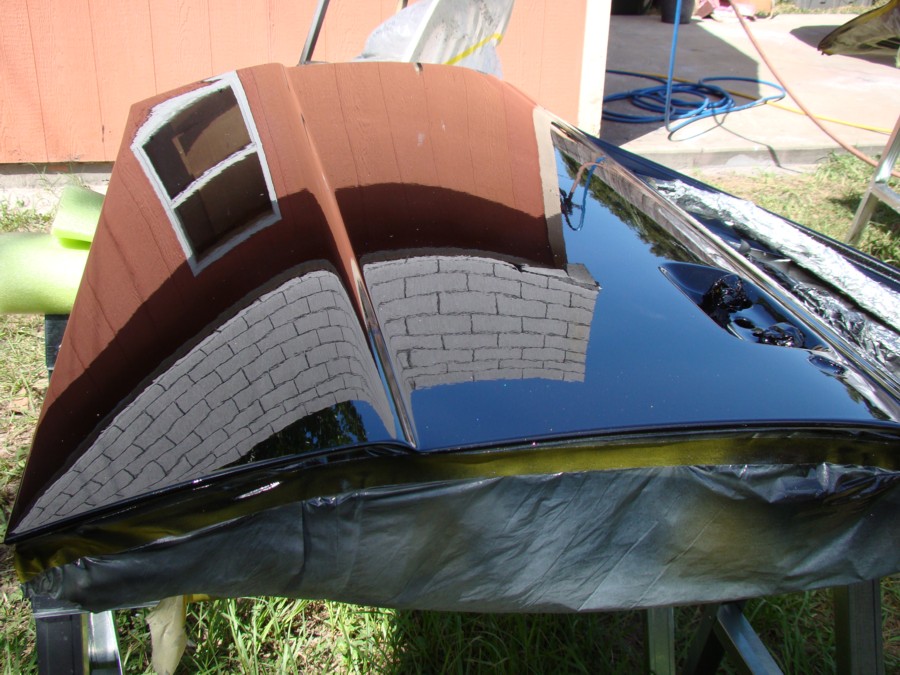

Early this morning I sprayed the outside of both doors and fenders. Even though the inside of the fenders are not visible when installed I did decide to spray that section Dark Shadow Grey to match the floor pan. Now they just need to dry for two days and I can go ahead and hang them back on the cab. I can’t wait to get the cab weather tight. After the doors are hung the solid rear window will go in next weekend. Just a quick color sand and buff around the window opening and I will be good to go.

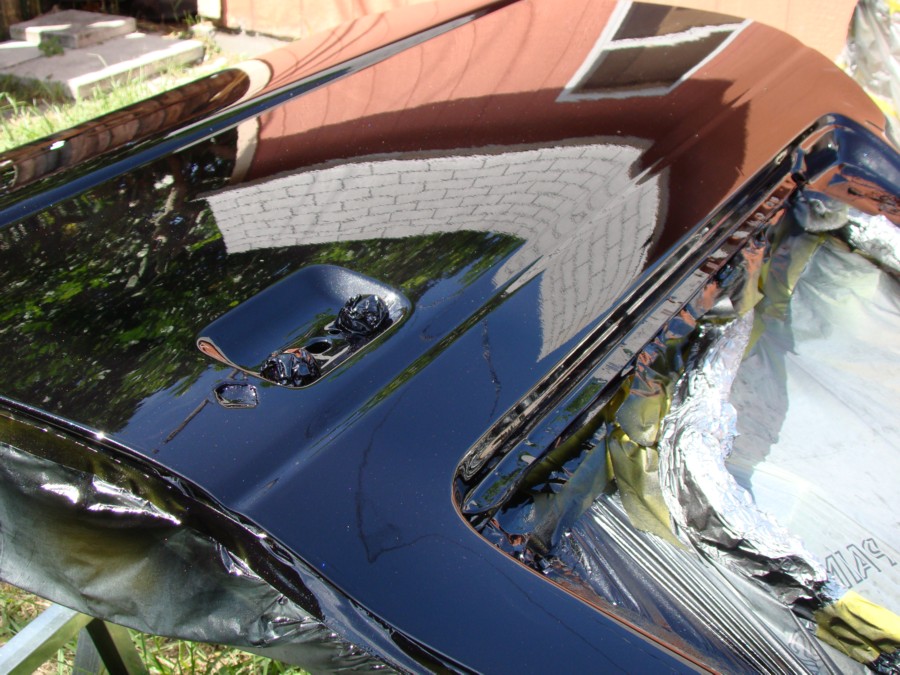

I paid special attention to the jamb along the hood opening and the door opening of the fender. The outside of the fender will be color sanded and polished but the jambs will be left with what ever comes out of the gun. I wanted to make sure these areas went down wet so there would be plenty of gloss and a very slick finish when the job is done. That way the towel will slide freely for years to come when I dry the jambs after washing the truck each week. : )

I paid special attention to the jamb along the hood opening and the door opening of the fender. The outside of the fender will be color sanded and polished but the jambs will be left with what ever comes out of the gun. I wanted to make sure these areas went down wet so there would be plenty of gloss and a very slick finish when the job is done. That way the towel will slide freely for years to come when I dry the jambs after washing the truck each week. : )

Last edited: