How To: Lethal Performance Budget Return kit install with pics!!!!

so i installed my budget return fuel system form lethal today. the install went very well and it took me and a buddy about 5hours from start to finish taking our time and lots of breaks lol. we did have the car on a lift which made things much easier so if you have access to one by all means use it! it can be done probably without much more difficulty but there wasn't really anyhting difficult about it just do yourself a favor and download all the instructions from lethal's website and print them out. i also printed out the how to thread for wiring with fpdm as that was the route i was taking but i read through everything before starting thoroughly to get my game plan down. i highly recommend this. start by inventorying your kit and make sure everything is present.

i started like this:

i followed the return system how to: http://www.svtperformance.com/forum...how-allowing-oe-type-fuel-pump-actuation.html for wiring it up using the fpdm as a trigger for the relays in order to prime the pumps with key on but not having them running full time unless the engine is running. it worked flawlessly and i will be updating this post at some point over the weekend with pics from the install and tips for others who go down this road in the future. i will be getting tuned in a couple days but using the fpdm instead of ditching it the car ran perfect (out of boost of course) and did not trip one code during my twenty minute or so drive home. i opted to keep the frps and for $29 more was worth it. i use torque for android and can still monitor my fuel pressure by keeping the sensor as part of the system. it stayed right at 39-40psi the whole time during cruise and only took a few minutes of idling to settle and smooth out, basically by the time i was done leak checking the system and set the lift down it was at steady pressure and the return line was full. it is a very well designed setup and looks really tough under the hood with that big DivisionX regulator!

i will start this off saying i saved a little bit of time by setting up the pumps in the hat and assembling the fuel pressure regulator the night before.

when i went to install the hat i did have to cut about 1/4" off the fuel lines at the pumps to get the depth straight. the measurements in the instructions must be off a lil but an easy way to get the pumps depth lined up is measure from the bottom side of the hat to the bottom of the fuel socks and get your distance between 6" & 6 1/4" and you will be in good shape. i bottomed out the pumps with the measurements in the instructions.

a good tip when installing the hat is to remove the return tube on the hat and leave it off until you go to drop it in the tank. 1, its hard to get the level sending unit bolted to the spine and 2, reattaching the float arm for the sender. once you clip back in the sending unit float arm them you can thread the the return fuel tube back into the underside of the hat and snug it down with an adjustable wrench.

will look like this when you are dropping the hat in after reconnecting the sender float arm:

**(for those who have never pulled pumps, be sure to only pull the stock hat up enough out unclip the float arm BEFORE you try and pull your stock pumps out! only lift enough to get it off and pull the arm out of the tank first otherwise you will break the sender and if you can, use an air compressor blower to clear the debris from around it before unbolting it!)**

another small issue and not sure if it was just me or all the DivisionX hats but the spine is thicker than the stock hat and the sending unit bracket did not line up with the bolt holes as the the bracket for the sending unit needed to be clearanced slightly to to line up. you could use dykes or snips, or like me about 10 seconds on the bench grinder. it just needs to be notched a tiny bit at the bottom of the sending unit bracket, do not modify the hat lol! you will see exactly where when you first try to line it up where it needs to be modified. not sure about the fore hat needing this or not. this was a very small inconvenience and not a big deal at all. once you install the sender you will want to connect the wires for it. be sure to retain one of your oem screws for the ground wire and also dont forget to heat shrink the signal wire:

here is a pic of the sender after it is mounted:

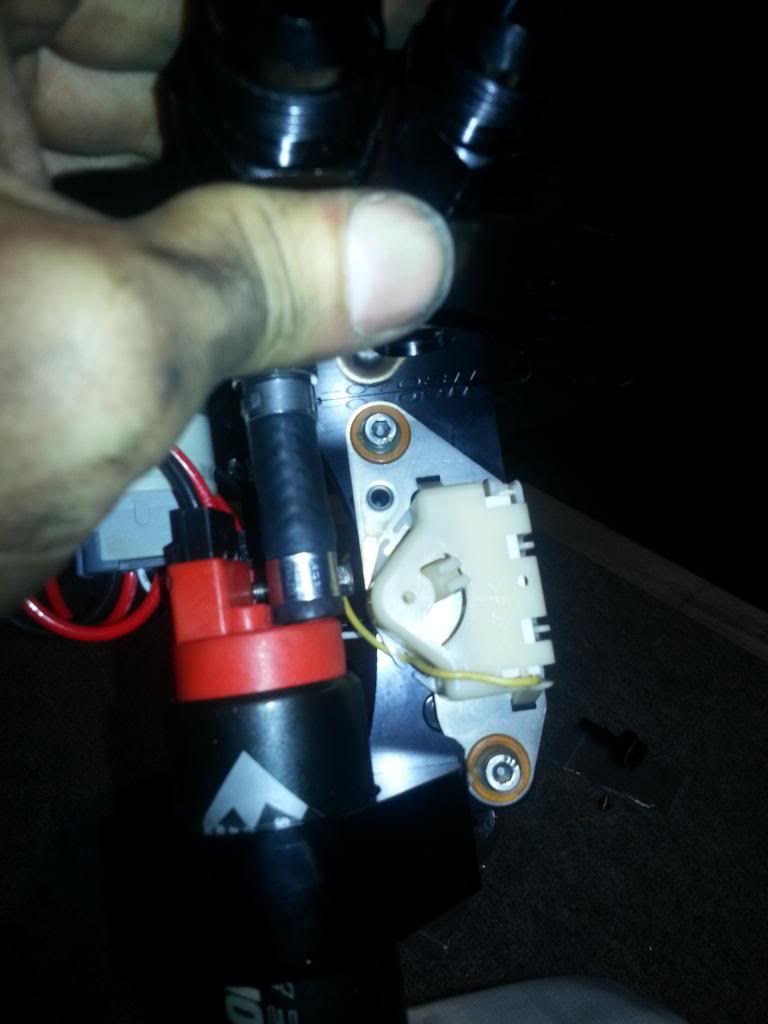

another tip for those stubborn barbed return line fittings is this, just dont make the vise grips too tight as in to damage the line. i used heat gun and some assembly lube and could only get the first barb by hand pressing down on a board. this worked very well but is kinda tricky but this should help you out! then just crimp the supplied clamp afterward:

these are all the pics i have currently of the install but the rest is very easy once you get this far and then all you have to do is run the return line back and secure it. i recommend starting at the front and working your way back. once you get the line ran to the tank area, start your wiring in whichever process you prefer. then reinstall tank. (another tip is removing your tailpipes. gives you more room especially if you are still and irs car).

my return line was installed as follows, (the instructions do an ok job of giving some guidance here as well):

i ran the return line straight back toward the firewall and used a couple cable ties to zip it to the wire harness that runs along the driver's side fuel rail and fished it down behind the engine in the area of the clutch fork. from there i actually ran it up and over the trans and ran it down the passenger side to the tank area. i ran it through the trans cross member mount on the car itself not the actual cross member and secured it with more cable ties. i ran it on the passenger side because the existing fuel line and brake lines all run on this side and i basically followed them down to the rear center section using more cable ties to secure it along the way. by doing this it was tucked up high in the trans/driveshaft tunnel and out of the way of danger from hot exhaust pipes. the instructions recommend running the line down the driver's side frame rail however its a lil close to the exhaust for my liking and since i drive my car on the streets a lot i didnt want it that close to the ground either because my car is lowered.

also, after running the line over the rear center section i veered off toward the gas tank filler neck and zipped it to the irs frame where its attached to the frame of the car (there are several locations for this that will work) and then with the extra line, (i had a few feet) i wrapped in a coil securing with more cable ties and have that resting on top of the passenger side of the gas tank with about 2ft out of it to attach to the fuel hat. i tried to make it as safe as possible from damage from the driveshaft, heat and road debris. the reason i didnt cut the excess return fuel line is incase i need to make a relocation in the future when i upgrade my system and or tank, new fuel rails and regulator setup etc...you never know when you may want to pull back some slack for future mods so my advice would be to coil whatever remaining line you have rather than cutting it to length.

once the tank is in and all is wired up, turn key to on position several times to prime the line/pumps and check for leaks. if none then start her up and let it idle for a few minutes while you check for leaks again and let the return line fill and get up to pressure. then set your base pressure at about 39-40 psi using an allen key and 9/16 wrench.

last but not least, drink some beers :beer: !!!

be easy on her until you get your tune and enjoy your new return fuel system!

hopefully this helps someone out in the future. feel free to add info to this thread or other tips and tricks that helped you out if you have done this install also.

so i installed my budget return fuel system form lethal today. the install went very well and it took me and a buddy about 5hours from start to finish taking our time and lots of breaks lol. we did have the car on a lift which made things much easier so if you have access to one by all means use it! it can be done probably without much more difficulty but there wasn't really anyhting difficult about it just do yourself a favor and download all the instructions from lethal's website and print them out. i also printed out the how to thread for wiring with fpdm as that was the route i was taking but i read through everything before starting thoroughly to get my game plan down. i highly recommend this. start by inventorying your kit and make sure everything is present.

i started like this:

i followed the return system how to: http://www.svtperformance.com/forum...how-allowing-oe-type-fuel-pump-actuation.html for wiring it up using the fpdm as a trigger for the relays in order to prime the pumps with key on but not having them running full time unless the engine is running. it worked flawlessly and i will be updating this post at some point over the weekend with pics from the install and tips for others who go down this road in the future. i will be getting tuned in a couple days but using the fpdm instead of ditching it the car ran perfect (out of boost of course) and did not trip one code during my twenty minute or so drive home. i opted to keep the frps and for $29 more was worth it. i use torque for android and can still monitor my fuel pressure by keeping the sensor as part of the system. it stayed right at 39-40psi the whole time during cruise and only took a few minutes of idling to settle and smooth out, basically by the time i was done leak checking the system and set the lift down it was at steady pressure and the return line was full. it is a very well designed setup and looks really tough under the hood with that big DivisionX regulator!

i will start this off saying i saved a little bit of time by setting up the pumps in the hat and assembling the fuel pressure regulator the night before.

when i went to install the hat i did have to cut about 1/4" off the fuel lines at the pumps to get the depth straight. the measurements in the instructions must be off a lil but an easy way to get the pumps depth lined up is measure from the bottom side of the hat to the bottom of the fuel socks and get your distance between 6" & 6 1/4" and you will be in good shape. i bottomed out the pumps with the measurements in the instructions.

a good tip when installing the hat is to remove the return tube on the hat and leave it off until you go to drop it in the tank. 1, its hard to get the level sending unit bolted to the spine and 2, reattaching the float arm for the sender. once you clip back in the sending unit float arm them you can thread the the return fuel tube back into the underside of the hat and snug it down with an adjustable wrench.

will look like this when you are dropping the hat in after reconnecting the sender float arm:

**(for those who have never pulled pumps, be sure to only pull the stock hat up enough out unclip the float arm BEFORE you try and pull your stock pumps out! only lift enough to get it off and pull the arm out of the tank first otherwise you will break the sender and if you can, use an air compressor blower to clear the debris from around it before unbolting it!)**

another small issue and not sure if it was just me or all the DivisionX hats but the spine is thicker than the stock hat and the sending unit bracket did not line up with the bolt holes as the the bracket for the sending unit needed to be clearanced slightly to to line up. you could use dykes or snips, or like me about 10 seconds on the bench grinder. it just needs to be notched a tiny bit at the bottom of the sending unit bracket, do not modify the hat lol! you will see exactly where when you first try to line it up where it needs to be modified. not sure about the fore hat needing this or not. this was a very small inconvenience and not a big deal at all. once you install the sender you will want to connect the wires for it. be sure to retain one of your oem screws for the ground wire and also dont forget to heat shrink the signal wire:

here is a pic of the sender after it is mounted:

another tip for those stubborn barbed return line fittings is this, just dont make the vise grips too tight as in to damage the line. i used heat gun and some assembly lube and could only get the first barb by hand pressing down on a board. this worked very well but is kinda tricky but this should help you out! then just crimp the supplied clamp afterward:

these are all the pics i have currently of the install but the rest is very easy once you get this far and then all you have to do is run the return line back and secure it. i recommend starting at the front and working your way back. once you get the line ran to the tank area, start your wiring in whichever process you prefer. then reinstall tank. (another tip is removing your tailpipes. gives you more room especially if you are still and irs car).

my return line was installed as follows, (the instructions do an ok job of giving some guidance here as well):

i ran the return line straight back toward the firewall and used a couple cable ties to zip it to the wire harness that runs along the driver's side fuel rail and fished it down behind the engine in the area of the clutch fork. from there i actually ran it up and over the trans and ran it down the passenger side to the tank area. i ran it through the trans cross member mount on the car itself not the actual cross member and secured it with more cable ties. i ran it on the passenger side because the existing fuel line and brake lines all run on this side and i basically followed them down to the rear center section using more cable ties to secure it along the way. by doing this it was tucked up high in the trans/driveshaft tunnel and out of the way of danger from hot exhaust pipes. the instructions recommend running the line down the driver's side frame rail however its a lil close to the exhaust for my liking and since i drive my car on the streets a lot i didnt want it that close to the ground either because my car is lowered.

also, after running the line over the rear center section i veered off toward the gas tank filler neck and zipped it to the irs frame where its attached to the frame of the car (there are several locations for this that will work) and then with the extra line, (i had a few feet) i wrapped in a coil securing with more cable ties and have that resting on top of the passenger side of the gas tank with about 2ft out of it to attach to the fuel hat. i tried to make it as safe as possible from damage from the driveshaft, heat and road debris. the reason i didnt cut the excess return fuel line is incase i need to make a relocation in the future when i upgrade my system and or tank, new fuel rails and regulator setup etc...you never know when you may want to pull back some slack for future mods so my advice would be to coil whatever remaining line you have rather than cutting it to length.

once the tank is in and all is wired up, turn key to on position several times to prime the line/pumps and check for leaks. if none then start her up and let it idle for a few minutes while you check for leaks again and let the return line fill and get up to pressure. then set your base pressure at about 39-40 psi using an allen key and 9/16 wrench.

last but not least, drink some beers :beer: !!!

be easy on her until you get your tune and enjoy your new return fuel system!

hopefully this helps someone out in the future. feel free to add info to this thread or other tips and tricks that helped you out if you have done this install also.

Last edited: