Seeing so many intake porting threads on here with folks wanting to know what they are trying to accomplish and what tools they need to accomplish it , I thought I would do a write up showing what I have done and what I use to do it. This tips would apply to any intake from stock to the CJ

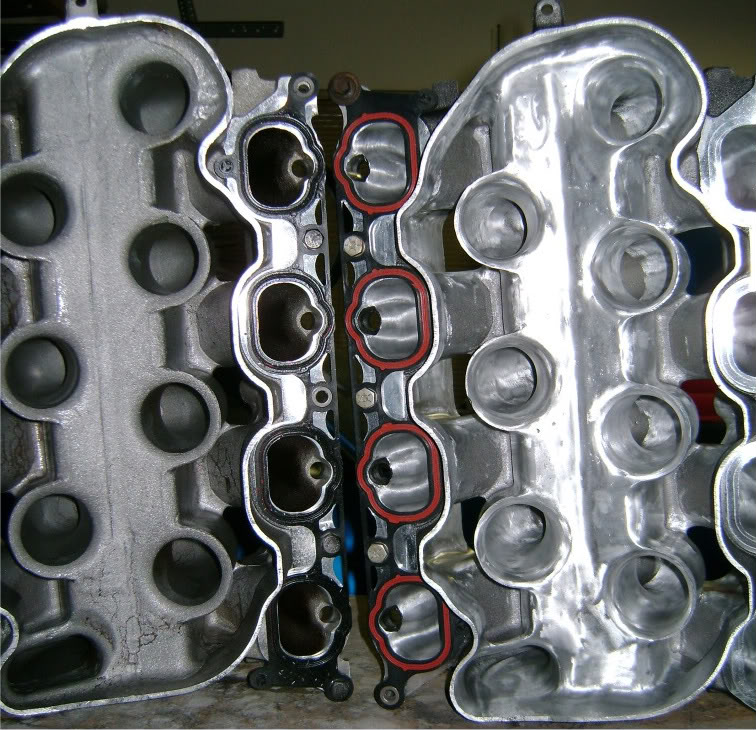

I had ported my Boss IM over a year ago , but as I'm not ready to shell the money out for a CJ setup I wanted to see how far I could take the Boss setup. What I planned to do was what I had done to 99-01 Cobra/03-04 Mach1 "C" head intakes... I was going to bisect the Boss along the plenum seam and port it fully from the inside out, like this...

Once I got the Boss IM off the car and inspected it I determined that the payoff would probably not be worth the effort/risk involved in attempting to cut it open. The main obstacle is the 3 pillars in the center of the Boss plenum...they appear to be plastic welded or bonded and I saw no feasible way to separate them. This combined with the fact that what I had seen in the few pictures of the inside of the Boss plenum from the internet did not jive with what I could see and feel inside my intake. I aborted that mission and instead decided that while it was off I would put some more time into the injector bung and port opening of the Boss, take some pictures and that would be the end of it.

As far as whats needed to do the job efficiently, I highly recommend an air grinder over electric as air provides much more control and finesse. The only thing I use my electric die grinder for is if I have hours of polishing to do like on the "C" head manifold pictured above. Here are the exact tools I used to do the job... 6" single cut ball end 3/8" dia bur and a Harbor Freight polishing kit.

I use single cut ferrous carbides for everything save when I need to remove alot of aluminum... once the shaping and blending starts I switch to the single cut burs , they remove material plenty fast and leave a much smoother finish making polishing easier. I set my air pressure to maintain 40-50psi with the tool wide open. The grinder should growl like a aggravated cat not scream like 2 cats fighting. keep the bur constantly moving and preferrably in multiple axis so you dont create low spots. use your fingers to determine where you need to remove material as much if not more than your eyes. Buy a good flexible LED light and move it around ofter to help show you high spots by the shadows they give off.

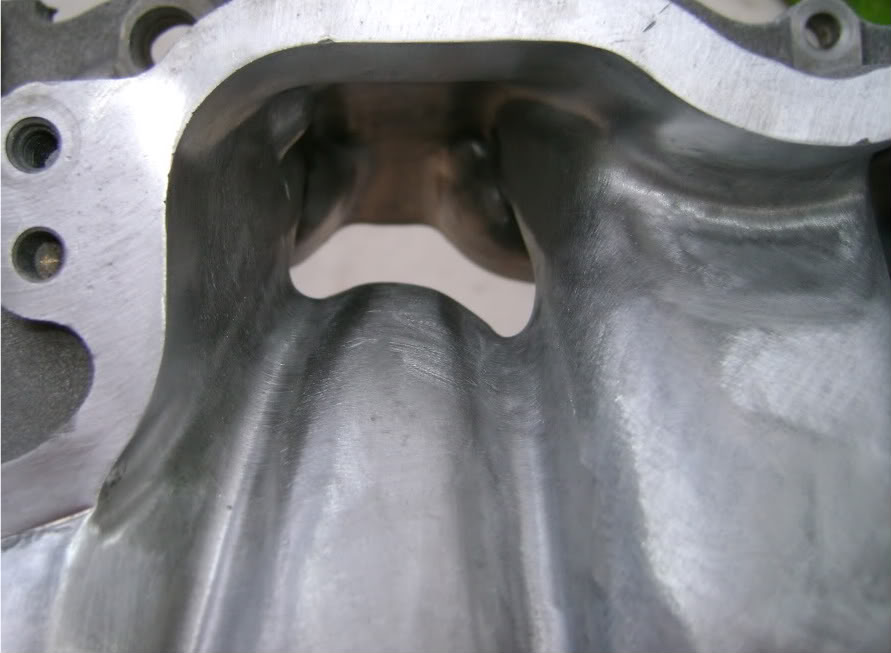

The Boss IM benefits most from having the absurdly large injector bunge radiused to a nice smooth conical shape and the eyebrows in the port opening corners removed.

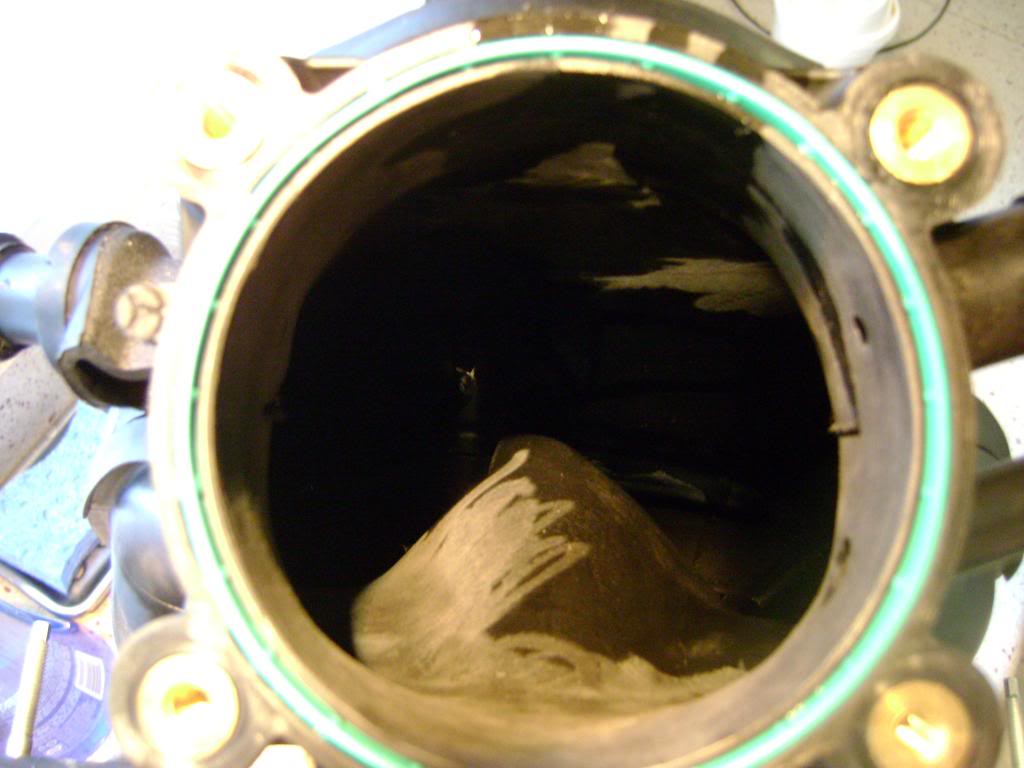

before pic(lifted from Shaun@AED)

After

removing the TB opening fins and smoothing out the the corners into the plenum is also recommended and I would say a necessity when running a 84.5mm TB.

degrease and wash it thouroughly inside and out before putting back on the car and you should be good to go.

I noticed an immediate difference once I stepped on the gas and this was verified at the track

I had ported my Boss IM over a year ago , but as I'm not ready to shell the money out for a CJ setup I wanted to see how far I could take the Boss setup. What I planned to do was what I had done to 99-01 Cobra/03-04 Mach1 "C" head intakes... I was going to bisect the Boss along the plenum seam and port it fully from the inside out, like this...

Once I got the Boss IM off the car and inspected it I determined that the payoff would probably not be worth the effort/risk involved in attempting to cut it open. The main obstacle is the 3 pillars in the center of the Boss plenum...they appear to be plastic welded or bonded and I saw no feasible way to separate them. This combined with the fact that what I had seen in the few pictures of the inside of the Boss plenum from the internet did not jive with what I could see and feel inside my intake. I aborted that mission and instead decided that while it was off I would put some more time into the injector bung and port opening of the Boss, take some pictures and that would be the end of it.

As far as whats needed to do the job efficiently, I highly recommend an air grinder over electric as air provides much more control and finesse. The only thing I use my electric die grinder for is if I have hours of polishing to do like on the "C" head manifold pictured above. Here are the exact tools I used to do the job... 6" single cut ball end 3/8" dia bur and a Harbor Freight polishing kit.

I use single cut ferrous carbides for everything save when I need to remove alot of aluminum... once the shaping and blending starts I switch to the single cut burs , they remove material plenty fast and leave a much smoother finish making polishing easier. I set my air pressure to maintain 40-50psi with the tool wide open. The grinder should growl like a aggravated cat not scream like 2 cats fighting. keep the bur constantly moving and preferrably in multiple axis so you dont create low spots. use your fingers to determine where you need to remove material as much if not more than your eyes. Buy a good flexible LED light and move it around ofter to help show you high spots by the shadows they give off.

The Boss IM benefits most from having the absurdly large injector bunge radiused to a nice smooth conical shape and the eyebrows in the port opening corners removed.

before pic(lifted from Shaun@AED)

After

removing the TB opening fins and smoothing out the the corners into the plenum is also recommended and I would say a necessity when running a 84.5mm TB.

degrease and wash it thouroughly inside and out before putting back on the car and you should be good to go.

I noticed an immediate difference once I stepped on the gas and this was verified at the track

Last edited: