I've been meaning to put together a post with pics I took when I installed the AEM UEGO Failsafe Wideband 02 with Boost Gauge in a steering wheel column gauge pod in my 2004 Mystichrome Cobra Terminator.

This thread will be under construction for a little while as I put it together. If anyone has any specific questions in the interim that I haven't gotten updated yet, feel free just to ask. I'm not sure how fast I will get everything posted into a final product. I found a lot of good sources that helped me and would like to consolidate it in this thread by including the links to those tutorials, pics and videos to hopefully help others answer a variety of questions.

Online Instruction Manual for installing the gauge (for future owners who buy this used and don't have a manual): http://www.aemelectronics.com/Images/Products/Installation Instructions 30-4900.pdf

Four helpful tips BEFORE you start:

1) Purchase a vacuum "T" sized 1/8 x 3/16 x 3/16 to connect the larger stock vacuum line and the smaller AEM gauge vacuum line. I bought an assortment package because wasn't sure which size "T" to use before I started, so hopefully this saves everyone time and money when you only need one "T".

2) Make sure you have a large wrench (think I used somewhere between 20MM and 23MM wrench?) to remove your stock 02 sensor and swap in the AEM wideband 02. I got to this part late at night, so all the stores were already closed. BUT, I already had a set of large wrenches purchased for another project. Think I got a low priced set from Harbor Freight?

3) Steering column gauge pod lays on top of the stock/factory plastic steering column. You do NOT need to take the plastic steering column apart. Other cars have the steering columns that have the plastic pieces break apart into two pieces, this is not one of them. If I would have known this it would have saved some time!

4) Purchase a 6 pin to 6 pin firewire in advance so you don't have to take a trip to electronics store after the car is apart. I think I paid about $5 at Fry's Electronics store. Best Buy had very few options and I think they wanted something outrageous like $30+. This is so you can connect your SCT handheld to your laptop to datalog.

Start by checking out this great video set, although I used a steering column pod gauge holder versus an A pillar gauge holder, so I ran my wires from different locations and my set up is different. But a vid/pic is worth a thousand words:

Wideband ONLY Install video 1 of 2 - YouTube

Wideband ONLY Install video 2 of 2 - YouTube

Step I: Run wire loom and vacuum line from glove box to speedo

Gauge can be configured to your taste: black or silver face with choice of where A/F and boost read (sweeping or digital) and also you choose between a black or silver bezel (once installed, you set up the gauge on your laptop via USB to display in the configuration of your choice matching the gauge face you installed). In this picture below, you also see the pretty standard column gauge pod. Disregard the Bose Soundlink II blue tooth speaker in the background. I used it to stream music from the Rdio app while working on the car.

I chose to run the silver bezel with the silver face reading digital A/F in the middle and the boost on the sweeping LED (once installed, at the very end, you will need to connect the gauge via the USB line I placed in my glove box to your laptop and open the AEM software program on your laptop to tell the gauge which face you are using so it will display properly)

Pic from the back and the two wire pins that plug in the back of the gauge.

To access the source to tap into the boost line, you will need to get behind the glove box. Its very simple, just lightly squeeze in the tabs that hold the glove box and it will drop down giving you access. The yellow line is a good source to put a "T" in to tap for the boost reading. In this pick I disconnected the line as it has a connector, no need to actually cut the line, just place a "T" in-line.

[/SIZE]

Pic of Vacuum "T" Assortment package. You can see the actual size "T" used. The AEM vacuum line is much smaller than the factory yellow line so the "T" used will have two larger nipples for the stock line and one smaller nipple for the AEM line.

1/8 x 3/16 x 3/16 Vacuum "T"

Pic showing the AEM boost/vacuum line "T" into the yellow factory boost line. I chose this location based on several recommendations seen in different threads. Also, no need to worry, the AEM vacuum line is plenty long enough to run from the "T" in the glove box to the AEM gauge on the column pod. I left the glove box open as later in the install you will want to route the wire loom here to connect to the firewire for datalogging as well as it is a good place to store the AEM gauge USB wire.

[/SIZE]

Pic of the radio, radio bezel/vent bezel and shifter bezel removed. Will need access to run the lines between the glove box andgauge cluster (speedo) and also will need to access shifter area when running lines from the actual wideband 02 sensor from under the car, through the shifter boot and up to the AEM gauge.

Pic of the gauge cluster (speedo). This was really straight forward (just a few Torx screws) if you have done it before on other cars EXCEPT for the headlight switch knob. The trick is to use a very small hooked pick, small screw driver, or in my case I used the smallest allen I had and lifted the tab to release the knob as I gently pulled it out. Here is a great how to I used (note step 3 & 4 is the difficult part) http://www.ehow.com/how_2188438_repl...d-mustang.html and also this is a great video walk through Gauge Cluster Removal Mustang GT - YouTube

Three items to disconnect: two wire pins and the yellow vacuum line that the stock gauge reads from

Here is where I ran the AEM vacuum line into the speedo area. I chose this location to avoid pinching the line. It was a bit of a PITA to feed the line through that area, but I think it is worth the effort to avoid pinching the line.

I also chose the same location to feed the AEM pin/wire loom that plugs into the back of the AEM gauge.

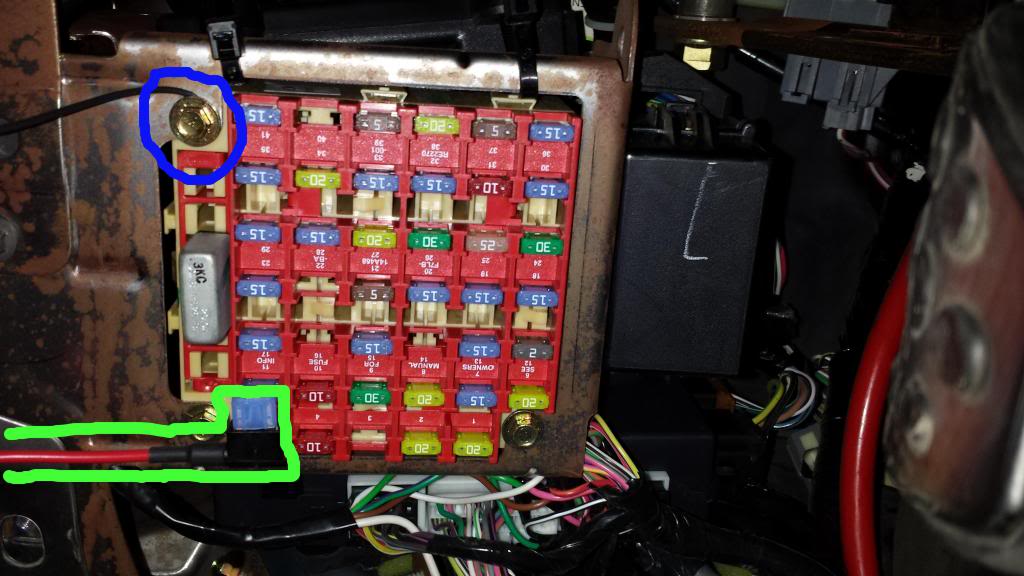

To get power to the gauge, I connected the red wire from to a 15 Amp add a fuse (outlined in green) and then used the bolt as a ground location for the black wire (circled in blue). As an FYI, if you don't put two 15 Amp fuses in the add a fuse, your traction control will be permanently off and your gauge cluster will take a minute to light up.

Because there are several wires in the wire loom that will need to run from the back of the speedo and travel behind the radio area to the glove box, I used electrical tape every 6 or so inches to keep all the wires together so none got lost and so they would easily pass through together. At the time of this photo, I had only attached the power (red wire) and ground (black wire) under the dash and had capped off the remaning wires until later when I got around to setting up the dataloging and failsafe features. Make sure you also run the USB wire as it will need to run to the glove box for you to access at a later time.

Pic showing the wires being routed behind the radio.

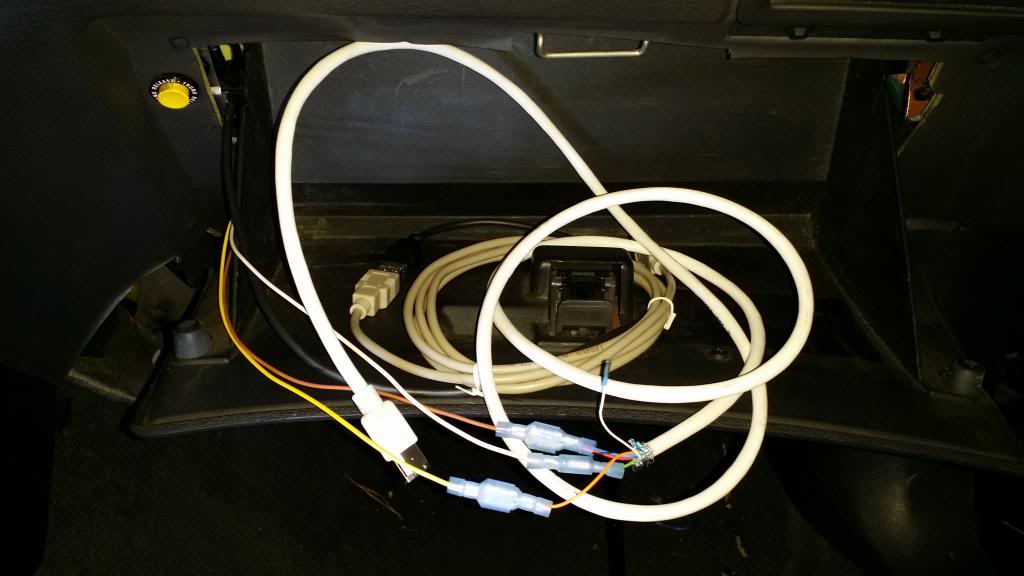

Pic showing the wire loom at its final destination behind the glove box. USB wire is there also, just not shown.

Step II: Route wire for 02 sensor and install 02 sensor in exhaust

Pic of me routing the wideband wire loom through shifter area to underneath the car.

Pic of the shifter plate and rubber sleave. At the bottom left you can see where I made a small hole and poked the wire loom coming from the 02 sensor under the car and into the cabin. I then routed this wire loom to the same location where the vacuum line and other wire loom was located so all items could be plugged into the back of the AEM gauge.

Pic with the new MGW shifter I threw on since I had it apart. Black wire loom can be seen poking out at the bottom left.

Pic underneath the car showing the AEM wideband 02 sensor installed on the driverside in stock rear 02 sensor location (after my cats in my MRT H-pipe). *My tuner had already turned off my rear 02 sensors, so this location works perfect. No need to weld in a bung, just plug and play.

There is a perfect cubby hole to tuck the wire plug under the car near the 02 sensor.

Here you can see how I am starting to stuff the wire and plug back in this cubby hole

And now you can see the plug and excess wire tucked in the cubby hole.

In this photo you can see the wire loom running up into the bottom of the shifter boot. Notice I pulled all the slack out of it so there would be no extra wire out hanging to drag or get caught on outside the car.

Once I had all three items routed to the steering column (wire plug for 02 sensor, the other wire plug loom(wires for power, ground, failsafe, datalog, etc) and vacuum line for boost reading) I test fit the speedo to make sure nothing was pinched. Everything looked good.

With speedo bezel reinstalled. All looks good, no lines pinched.

Then just push down the steering column gauge holder and route lines through the hole and attach gauge. Then push the gauge into the gauge pod hole.

At this point, turn the key on to verify the gauge is working properly (even though you should have checked when you hooked up the power and ground earlier, it always is important to verify nothing got loose while).

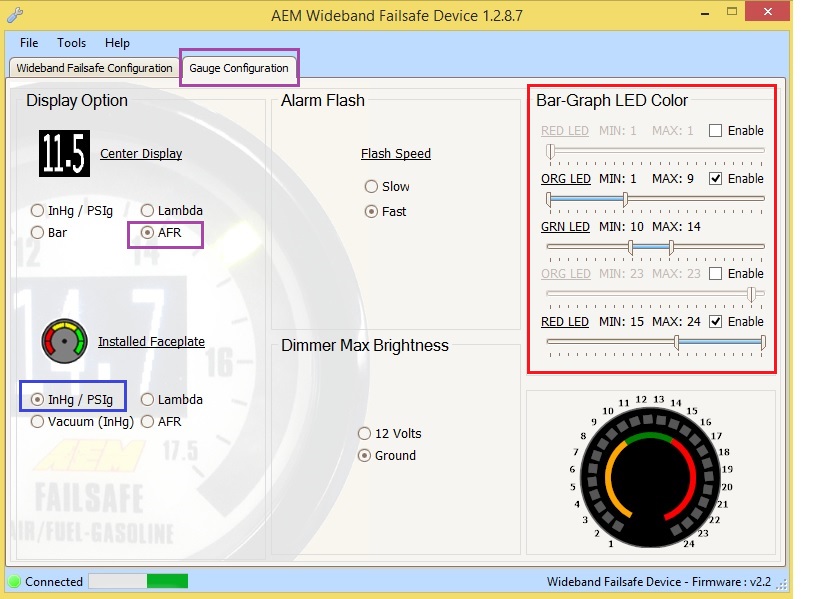

At this point, you may want to break out your laptop, connect it to the USB you ran to the glove box and open up the AEM software so you can configure the gauge to read properly based on the gauge face you chose. The pic below is of the screen in the software where you choose the set up. I like the feature where you decided what color LED and when it comes on with the sweeping LED outer gauge.

I chose A/F in the center and boost on the outer sweep. Since this is a supercharged vehicle, and I know where the boost will be all the time, I set up orange to show vacumm up through 9psi, then green from 10psi to 14psi and at 15psi and higher it turns red. I think sometimes in 4th the boost will stretch up to 15, so this gives me an easy glance verification.

At this point, I suggest taking a test drive to see your gauge in action and make sure its working properly before going to the next step of putting everything back together and then making your firewire so you can datalog your A/F and boost on your SCT LiveLink software.

Step III: Build firewire to use for dataloging

Here is the thread I followed to build my own firewire so I could connect the AEM 02 readings to the SCT X3 LiveLink in order to be able to datalog. This will also allow you to datalog the boost readings as well. http://www.focusfanatics.com/forum/s...18&postcount=3

As a heads up, your firewire may have a different "wire color scheme" as has been noted by many. In the photo of the firewire plug, he shows AEM 1 and AEM 2 also known as Analog 1 and Analog 2. Although in the same location, my wire colors were the different: Orange was Analog 1, Green Analog 2, white was unused and the remaining three wires colored red, blue and black were the grounds. PLEASE NOTE, it is not necessary to attach the grounds to the AEM brown wire ground. The one ground installed under the dash works fine, but if you want to go all out, you can tie the three grounds together as pictured. However, all you need from the firewire is Analog 1 (which will attach to the AEM yellow boost wire)and Analog 2 (which will attach to the AEM white A/F wire).

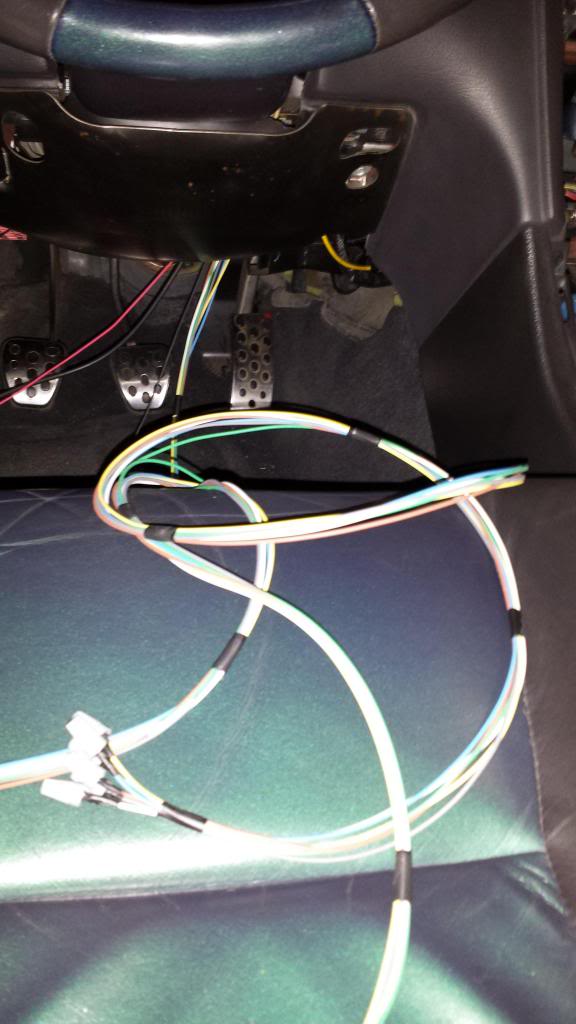

In the pic, I attached female ends to the wires so I can easily connect/disconnect the firewire to the AEM wires. Although I just keep them attached and the firewire stays in the glove box.

In this pic, I have the AEM wire loom we ran earlier to our glove box. I added male ends to the yellow wire (boost which will attach to analog 1 of the firewire), white wire (A/F which will attach to analog 2 of the firewire) and the brown wire is for ground, which is not necessary, but I added a male end to attach to the grounds from the firewire.

Notice the green zip tie, it is actually readjustable. I used it to neatly bundle the extra wire as AEM provided more than enough wire length.

This pic shows I zip tied the excess wire loom with caped off wires I didn't use behind the glove box and will only be pulling the white, yellow and brown wire and USB cable into the glove box.

Here you can see the glove box is back in position and just the wires needed are stored in the glove box.

Here you can see the thick white firewire is attached to the AEM wires and that I added an extension to the USB cable for extra reach to my laptop.

This thread will be under construction for a little while as I put it together. If anyone has any specific questions in the interim that I haven't gotten updated yet, feel free just to ask. I'm not sure how fast I will get everything posted into a final product. I found a lot of good sources that helped me and would like to consolidate it in this thread by including the links to those tutorials, pics and videos to hopefully help others answer a variety of questions.

Online Instruction Manual for installing the gauge (for future owners who buy this used and don't have a manual): http://www.aemelectronics.com/Images/Products/Installation Instructions 30-4900.pdf

Four helpful tips BEFORE you start:

1) Purchase a vacuum "T" sized 1/8 x 3/16 x 3/16 to connect the larger stock vacuum line and the smaller AEM gauge vacuum line. I bought an assortment package because wasn't sure which size "T" to use before I started, so hopefully this saves everyone time and money when you only need one "T".

2) Make sure you have a large wrench (think I used somewhere between 20MM and 23MM wrench?) to remove your stock 02 sensor and swap in the AEM wideband 02. I got to this part late at night, so all the stores were already closed. BUT, I already had a set of large wrenches purchased for another project. Think I got a low priced set from Harbor Freight?

3) Steering column gauge pod lays on top of the stock/factory plastic steering column. You do NOT need to take the plastic steering column apart. Other cars have the steering columns that have the plastic pieces break apart into two pieces, this is not one of them. If I would have known this it would have saved some time!

4) Purchase a 6 pin to 6 pin firewire in advance so you don't have to take a trip to electronics store after the car is apart. I think I paid about $5 at Fry's Electronics store. Best Buy had very few options and I think they wanted something outrageous like $30+. This is so you can connect your SCT handheld to your laptop to datalog.

Start by checking out this great video set, although I used a steering column pod gauge holder versus an A pillar gauge holder, so I ran my wires from different locations and my set up is different. But a vid/pic is worth a thousand words:

Wideband ONLY Install video 1 of 2 - YouTube

Wideband ONLY Install video 2 of 2 - YouTube

Step I: Run wire loom and vacuum line from glove box to speedo

Gauge can be configured to your taste: black or silver face with choice of where A/F and boost read (sweeping or digital) and also you choose between a black or silver bezel (once installed, you set up the gauge on your laptop via USB to display in the configuration of your choice matching the gauge face you installed). In this picture below, you also see the pretty standard column gauge pod. Disregard the Bose Soundlink II blue tooth speaker in the background. I used it to stream music from the Rdio app while working on the car.

I chose to run the silver bezel with the silver face reading digital A/F in the middle and the boost on the sweeping LED (once installed, at the very end, you will need to connect the gauge via the USB line I placed in my glove box to your laptop and open the AEM software program on your laptop to tell the gauge which face you are using so it will display properly)

Pic from the back and the two wire pins that plug in the back of the gauge.

To access the source to tap into the boost line, you will need to get behind the glove box. Its very simple, just lightly squeeze in the tabs that hold the glove box and it will drop down giving you access. The yellow line is a good source to put a "T" in to tap for the boost reading. In this pick I disconnected the line as it has a connector, no need to actually cut the line, just place a "T" in-line.

[/SIZE]

Pic of Vacuum "T" Assortment package. You can see the actual size "T" used. The AEM vacuum line is much smaller than the factory yellow line so the "T" used will have two larger nipples for the stock line and one smaller nipple for the AEM line.

1/8 x 3/16 x 3/16 Vacuum "T"

Pic showing the AEM boost/vacuum line "T" into the yellow factory boost line. I chose this location based on several recommendations seen in different threads. Also, no need to worry, the AEM vacuum line is plenty long enough to run from the "T" in the glove box to the AEM gauge on the column pod. I left the glove box open as later in the install you will want to route the wire loom here to connect to the firewire for datalogging as well as it is a good place to store the AEM gauge USB wire.

[/SIZE]

Pic of the radio, radio bezel/vent bezel and shifter bezel removed. Will need access to run the lines between the glove box andgauge cluster (speedo) and also will need to access shifter area when running lines from the actual wideband 02 sensor from under the car, through the shifter boot and up to the AEM gauge.

Pic of the gauge cluster (speedo). This was really straight forward (just a few Torx screws) if you have done it before on other cars EXCEPT for the headlight switch knob. The trick is to use a very small hooked pick, small screw driver, or in my case I used the smallest allen I had and lifted the tab to release the knob as I gently pulled it out. Here is a great how to I used (note step 3 & 4 is the difficult part) http://www.ehow.com/how_2188438_repl...d-mustang.html and also this is a great video walk through Gauge Cluster Removal Mustang GT - YouTube

Three items to disconnect: two wire pins and the yellow vacuum line that the stock gauge reads from

Here is where I ran the AEM vacuum line into the speedo area. I chose this location to avoid pinching the line. It was a bit of a PITA to feed the line through that area, but I think it is worth the effort to avoid pinching the line.

I also chose the same location to feed the AEM pin/wire loom that plugs into the back of the AEM gauge.

To get power to the gauge, I connected the red wire from to a 15 Amp add a fuse (outlined in green) and then used the bolt as a ground location for the black wire (circled in blue). As an FYI, if you don't put two 15 Amp fuses in the add a fuse, your traction control will be permanently off and your gauge cluster will take a minute to light up.

Because there are several wires in the wire loom that will need to run from the back of the speedo and travel behind the radio area to the glove box, I used electrical tape every 6 or so inches to keep all the wires together so none got lost and so they would easily pass through together. At the time of this photo, I had only attached the power (red wire) and ground (black wire) under the dash and had capped off the remaning wires until later when I got around to setting up the dataloging and failsafe features. Make sure you also run the USB wire as it will need to run to the glove box for you to access at a later time.

Pic showing the wires being routed behind the radio.

Pic showing the wire loom at its final destination behind the glove box. USB wire is there also, just not shown.

Step II: Route wire for 02 sensor and install 02 sensor in exhaust

Pic of me routing the wideband wire loom through shifter area to underneath the car.

Pic of the shifter plate and rubber sleave. At the bottom left you can see where I made a small hole and poked the wire loom coming from the 02 sensor under the car and into the cabin. I then routed this wire loom to the same location where the vacuum line and other wire loom was located so all items could be plugged into the back of the AEM gauge.

Pic with the new MGW shifter I threw on since I had it apart. Black wire loom can be seen poking out at the bottom left.

Pic underneath the car showing the AEM wideband 02 sensor installed on the driverside in stock rear 02 sensor location (after my cats in my MRT H-pipe). *My tuner had already turned off my rear 02 sensors, so this location works perfect. No need to weld in a bung, just plug and play.

There is a perfect cubby hole to tuck the wire plug under the car near the 02 sensor.

Here you can see how I am starting to stuff the wire and plug back in this cubby hole

And now you can see the plug and excess wire tucked in the cubby hole.

In this photo you can see the wire loom running up into the bottom of the shifter boot. Notice I pulled all the slack out of it so there would be no extra wire out hanging to drag or get caught on outside the car.

Once I had all three items routed to the steering column (wire plug for 02 sensor, the other wire plug loom(wires for power, ground, failsafe, datalog, etc) and vacuum line for boost reading) I test fit the speedo to make sure nothing was pinched. Everything looked good.

With speedo bezel reinstalled. All looks good, no lines pinched.

Then just push down the steering column gauge holder and route lines through the hole and attach gauge. Then push the gauge into the gauge pod hole.

At this point, turn the key on to verify the gauge is working properly (even though you should have checked when you hooked up the power and ground earlier, it always is important to verify nothing got loose while).

At this point, you may want to break out your laptop, connect it to the USB you ran to the glove box and open up the AEM software so you can configure the gauge to read properly based on the gauge face you chose. The pic below is of the screen in the software where you choose the set up. I like the feature where you decided what color LED and when it comes on with the sweeping LED outer gauge.

I chose A/F in the center and boost on the outer sweep. Since this is a supercharged vehicle, and I know where the boost will be all the time, I set up orange to show vacumm up through 9psi, then green from 10psi to 14psi and at 15psi and higher it turns red. I think sometimes in 4th the boost will stretch up to 15, so this gives me an easy glance verification.

At this point, I suggest taking a test drive to see your gauge in action and make sure its working properly before going to the next step of putting everything back together and then making your firewire so you can datalog your A/F and boost on your SCT LiveLink software.

Step III: Build firewire to use for dataloging

Here is the thread I followed to build my own firewire so I could connect the AEM 02 readings to the SCT X3 LiveLink in order to be able to datalog. This will also allow you to datalog the boost readings as well. http://www.focusfanatics.com/forum/s...18&postcount=3

As a heads up, your firewire may have a different "wire color scheme" as has been noted by many. In the photo of the firewire plug, he shows AEM 1 and AEM 2 also known as Analog 1 and Analog 2. Although in the same location, my wire colors were the different: Orange was Analog 1, Green Analog 2, white was unused and the remaining three wires colored red, blue and black were the grounds. PLEASE NOTE, it is not necessary to attach the grounds to the AEM brown wire ground. The one ground installed under the dash works fine, but if you want to go all out, you can tie the three grounds together as pictured. However, all you need from the firewire is Analog 1 (which will attach to the AEM yellow boost wire)and Analog 2 (which will attach to the AEM white A/F wire).

In the pic, I attached female ends to the wires so I can easily connect/disconnect the firewire to the AEM wires. Although I just keep them attached and the firewire stays in the glove box.

In this pic, I have the AEM wire loom we ran earlier to our glove box. I added male ends to the yellow wire (boost which will attach to analog 1 of the firewire), white wire (A/F which will attach to analog 2 of the firewire) and the brown wire is for ground, which is not necessary, but I added a male end to attach to the grounds from the firewire.

Notice the green zip tie, it is actually readjustable. I used it to neatly bundle the extra wire as AEM provided more than enough wire length.

This pic shows I zip tied the excess wire loom with caped off wires I didn't use behind the glove box and will only be pulling the white, yellow and brown wire and USB cable into the glove box.

Here you can see the glove box is back in position and just the wires needed are stored in the glove box.

Here you can see the thick white firewire is attached to the AEM wires and that I added an extension to the USB cable for extra reach to my laptop.

Last edited: