Cams: Comp Cams 106360

Valve Lift: .475 Intake / .450 Exhaust

Lobe Lift: .263 Intake / .250 Exhaust

Intake Duration: 230 degrees @ .050 valve lift

Exhaust Duration: 232 degrees @ .050 valve lift

Base Circle Runout Tolerance: .0005" or less

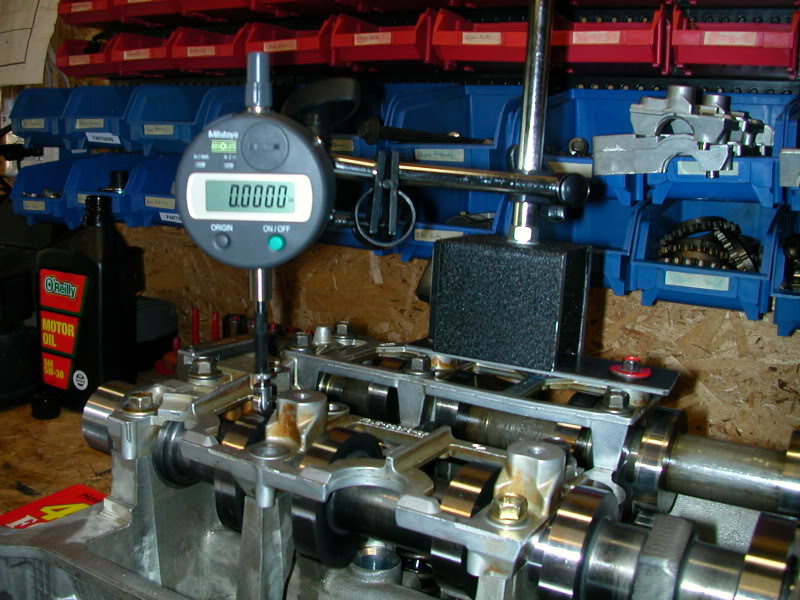

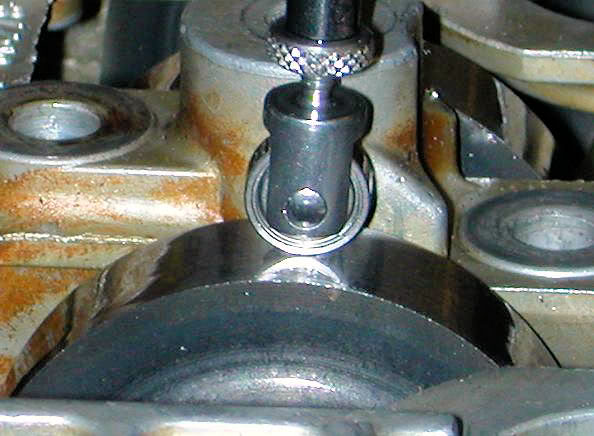

Last night I measured the left intake camshaft. I am using a .0001" digital dial indicator, and a roller tip. There is no measureable runout on the tip. The roller tip is used to minimize pointer deflection, in lieu of dragging a round tip on cam lobes. I also use the shortest overall pointer length possible to minimize deflection. Preloading the pointer down assists with this.

Maximum tolerance for base circle runout is .0005", per J. Mihovetz's recommendation in the now ancient "Crower Cams" topic on modularfords from 2006.

http://www.modularfords.com/threads/45339-Crower-Cams

I should note that Comp Cams tolerance is equal or less than .0015." This tolerance is three times higher than listed above. Therefore it is good practice to check. Comp Cams does report that it is not uncommon to see .0001" or less base circle runout on their products, according to tech support.

Of the 8 lobes on the left intake, the highest measureable base circle runout was .0003". I found this on 2 of 8 lobes. The runout on the Comp Cams is highest just before one of the lobe opening points. The rest of the 6 lobes all measured .0001".

This is the following runout report on the left intake cam:

Left Intake Comp Cams 106360

1: .0003"

2: .0003"

3: .0001"

4: .0001"

5: .0001"

6: .0001"

7: .0001"

8: .0001"

One other note...

I have already checked lobe lift across all 32. They are not all uniform...although most are close. One came out .002" less than the others. Multiplying by the 1.81 rocker ratio, the valve will open .0036" less than the rest . In my case, it will produce ~.472" valve lift instead of .475" lift.

I feel it's important to blueprint lobe lift variations as a consideration for inspection of piston to valve clearance. If you set piston to valve with a lobe that is "short", the rest of your clearances will be tighter.

-Steve

Valve Lift: .475 Intake / .450 Exhaust

Lobe Lift: .263 Intake / .250 Exhaust

Intake Duration: 230 degrees @ .050 valve lift

Exhaust Duration: 232 degrees @ .050 valve lift

Base Circle Runout Tolerance: .0005" or less

Last night I measured the left intake camshaft. I am using a .0001" digital dial indicator, and a roller tip. There is no measureable runout on the tip. The roller tip is used to minimize pointer deflection, in lieu of dragging a round tip on cam lobes. I also use the shortest overall pointer length possible to minimize deflection. Preloading the pointer down assists with this.

Maximum tolerance for base circle runout is .0005", per J. Mihovetz's recommendation in the now ancient "Crower Cams" topic on modularfords from 2006.

http://www.modularfords.com/threads/45339-Crower-Cams

I should note that Comp Cams tolerance is equal or less than .0015." This tolerance is three times higher than listed above. Therefore it is good practice to check. Comp Cams does report that it is not uncommon to see .0001" or less base circle runout on their products, according to tech support.

Of the 8 lobes on the left intake, the highest measureable base circle runout was .0003". I found this on 2 of 8 lobes. The runout on the Comp Cams is highest just before one of the lobe opening points. The rest of the 6 lobes all measured .0001".

This is the following runout report on the left intake cam:

Left Intake Comp Cams 106360

1: .0003"

2: .0003"

3: .0001"

4: .0001"

5: .0001"

6: .0001"

7: .0001"

8: .0001"

One other note...

I have already checked lobe lift across all 32. They are not all uniform...although most are close. One came out .002" less than the others. Multiplying by the 1.81 rocker ratio, the valve will open .0036" less than the rest . In my case, it will produce ~.472" valve lift instead of .475" lift.

I feel it's important to blueprint lobe lift variations as a consideration for inspection of piston to valve clearance. If you set piston to valve with a lobe that is "short", the rest of your clearances will be tighter.

-Steve

Last edited by a moderator: