You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I got a 3D printer...

- Thread starter HISSMAN

- Start date

- Status

- Not open for further replies.

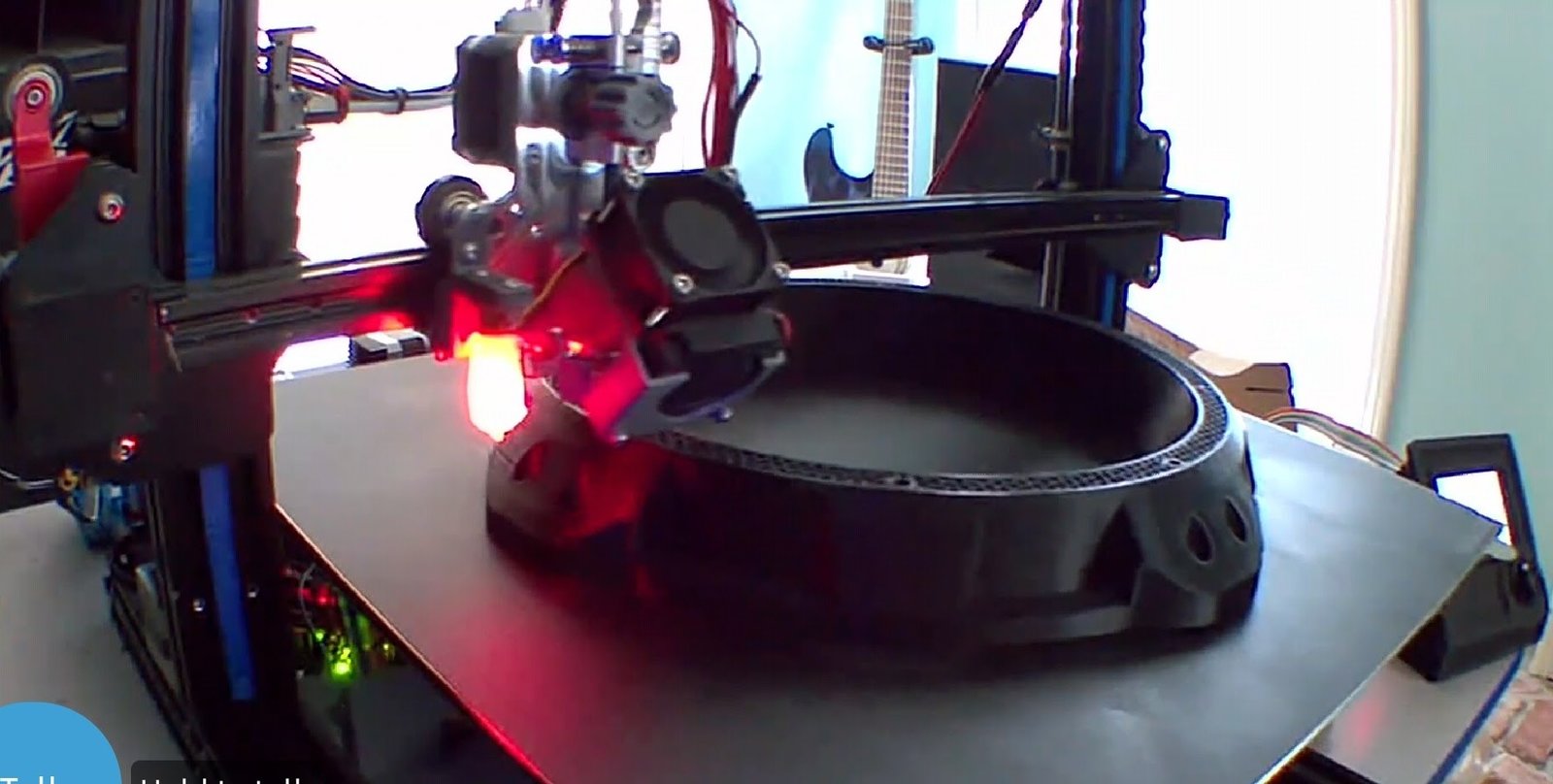

New design...I had to make an adapter to mount a better subwoofer. I had to design it to be strong and allow for the deeper 10" JL. It turned out great! I will be installing the amp and hooking it up sometime this weekend.

Last edited:

Haven’t done much with ours lately, last thing we printed were some prototype brackets for a friend

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I really love these 3D printers, but there is no way I could come close to the stuff you guys are doing. I have zero CAD, engineering background. I give you a lot of credit for the stuff you're producing.

I really love these 3D printers, but there is no way I could come close to the stuff you guys are doing. I have zero CAD, engineering background. I give you a lot of credit for the stuff you're producing.

I can't really take credit for anything but running the slicer program to actually print it. Most stuff we've printed has been from sites you can download designs. The brackets were drawn up from scratch by my GT Engineering major cousin, his dad runs a machine shop so at this point if I need something drawn up I bribe them.

My dad has messed around with some of the free design stuff online (tinker cad might be one of em) and is starting to get the hang of it. He started just drawing simple shapes to get the hang of it

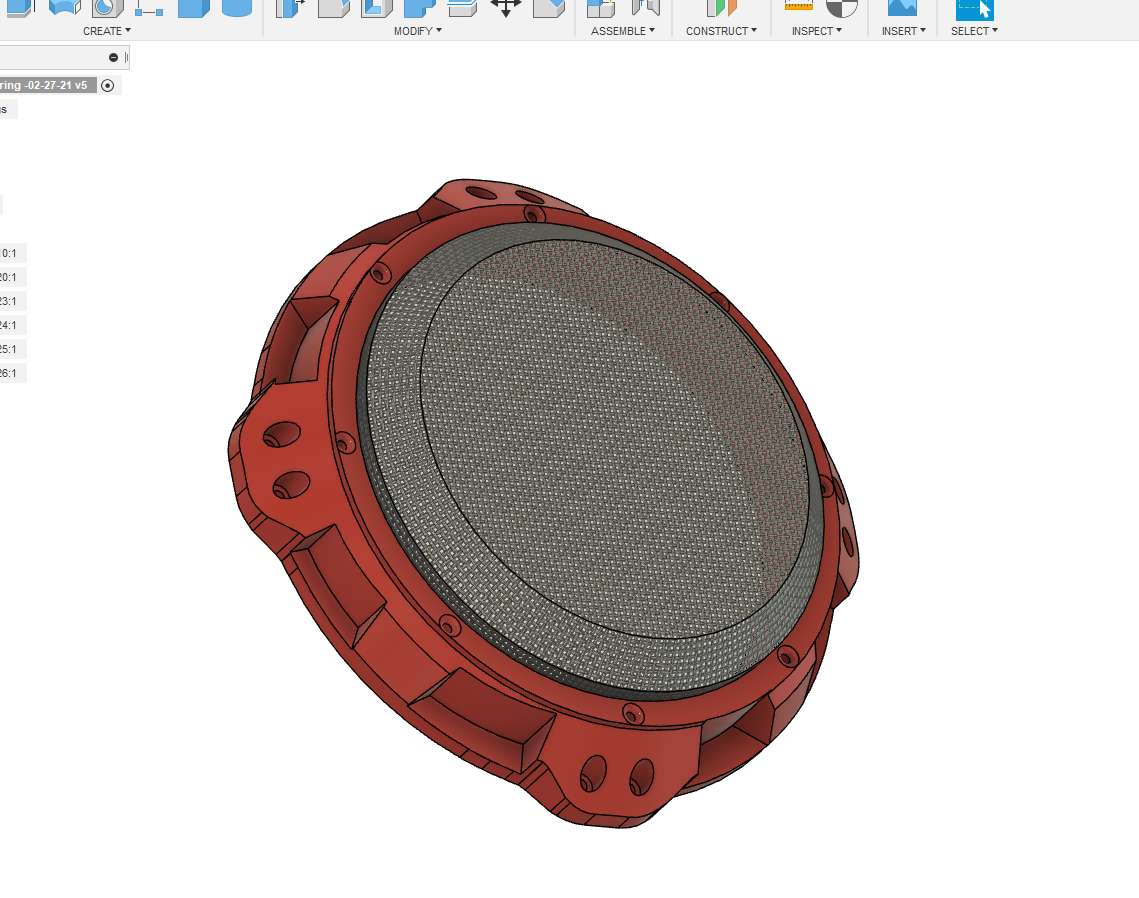

This is my final cad design...I had to make about 8 different templates or versions before I finally got it right. The good thing is I could just print a small section of each version and figure out what adjustments were needed. It took about 4 weeks of after work R&D.

I can understand downloading designs for non-custom applications. I more talking about, say, designing a custom part and printing it. That requires engineering and CAD experience. For those that have that some level of expertise (like Jeff), custom making parts is awesome, albeit time consuming. I really find this whole 3D printing topic intriguing.I can't really take credit for anything but running the slicer program to actually print it. Most stuff we've printed has been from sites you can download designs. The brackets were drawn up from scratch by my GT Engineering major cousin, his dad runs a machine shop so at this point if I need something drawn up I bribe them.

My dad has messed around with some of the free design stuff online (tinker cad might be one of em) and is starting to get the hang of it. He started just drawing simple shapes to get the hang of it

I went to my orthodontist a couple of months ago to get a new retainer, and they ended up using a new technology which I'm all but sure is in-house 3D printing. They used a camera to take about two dozen photos of my teeth from inside my mouth, and later that day presented me with the clear, thin plastic retainers. It had to have been a 3D printing application.

I can understand downloading designs for non-custom applications. I more talking about, say, designing a custom part and printing it. That requires engineering and CAD experience. For those that have that some level of expertise (like Jeff), custom making parts is awesome, albeit time consuming. I really find this whole 3D printing topic intriguing.

I went to my orthodontist a couple of months ago to get a new retainer, and they ended up using a new technology which I'm all but sure is in-house 3D printing. They used a camera to take about two dozen photos of my teeth from inside my mouth, and later that day presented me with the clear, thin plastic retainers. It had to have been a 3D printing application.

Bob, it is really fun, and not as hard to learn as you would imagine. Though, I will admit I pick up on things pretty quick. I needed custom firmware and software to run my printer, so I learned to code while I was on vacation. I have since written my own wares. I am currently working on some software to manage my streaming library on my home server that will do exactly what I want to do, and not what some guy sitting in a computer lab felt it needed to do. But, you can download a free version of Fusion 360. I recommend watching some tutorials and playing around with it. It isn't so bad once you get your eyes used to seeing a 3d space on a 2d monitor.

I can understand downloading designs for non-custom applications. I more talking about, say, designing a custom part and printing it. That requires engineering and CAD experience. For those that have that some level of expertise (like Jeff), custom making parts is awesome, albeit time consuming. I really find this whole 3D printing topic intriguing.

I went to my orthodontist a couple of months ago to get a new retainer, and they ended up using a new technology which I'm all but sure is in-house 3D printing. They used a camera to take about two dozen photos of my teeth from inside my mouth, and later that day presented me with the clear, thin plastic retainers. It had to have been a 3D printing application.

It had to be, I'd hate to know what that kind of printer costs.

The good things is these machines are CHEAP to run. A huge roll of filament is $20-$25. It uses about the same power as a 60watt bulb to run so even if you design something and isn't right your actual out of pocket expense is literally only a couple bucks so it's a low stakes game. You're not likely to print anything structural as it won't hold up to a whole lot anyway unless you go waaaaay off the deep end and start printing carbon fiber reinforced stuff.

I'll admit I've lost a little interest being so busy and accepting the fact that it would be VERY difficult to make any noteworthy amount of money due to the slow speed and finish quality. That's not to say you can't find some little niche that might do well.

Post a project you do with that new printer. Should be fun for you.

Will do. It'll be awhile. They said 3 weeks for delivery. This company is based on Czechoslovakia. In the meantime, I'm going to familiarize myself with 3d software.Post a project you do with that new printer. Should be fun for you.

Move on, nothing to see here.

Will do. It'll be awhile. They said 3 weeks for delivery. This company is based on Czechoslovakia. In the meantime, I'm going to familiarize myself with 3d software.

Move on, nothing to see here.

I hope they're not based in Czechoslovokia... that printer may only print red things!

I need to get off my butt and get going on one of these.

I dont see it at all as a money making opportunity (although im sure you could).

As a DIY guy, i see this as an absolute must-have tool in your shop to make those one-off parts only you might need for xyz project.

So cool guys... keep the pics/projects coming!

I dont see it at all as a money making opportunity (although im sure you could).

As a DIY guy, i see this as an absolute must-have tool in your shop to make those one-off parts only you might need for xyz project.

So cool guys... keep the pics/projects coming!

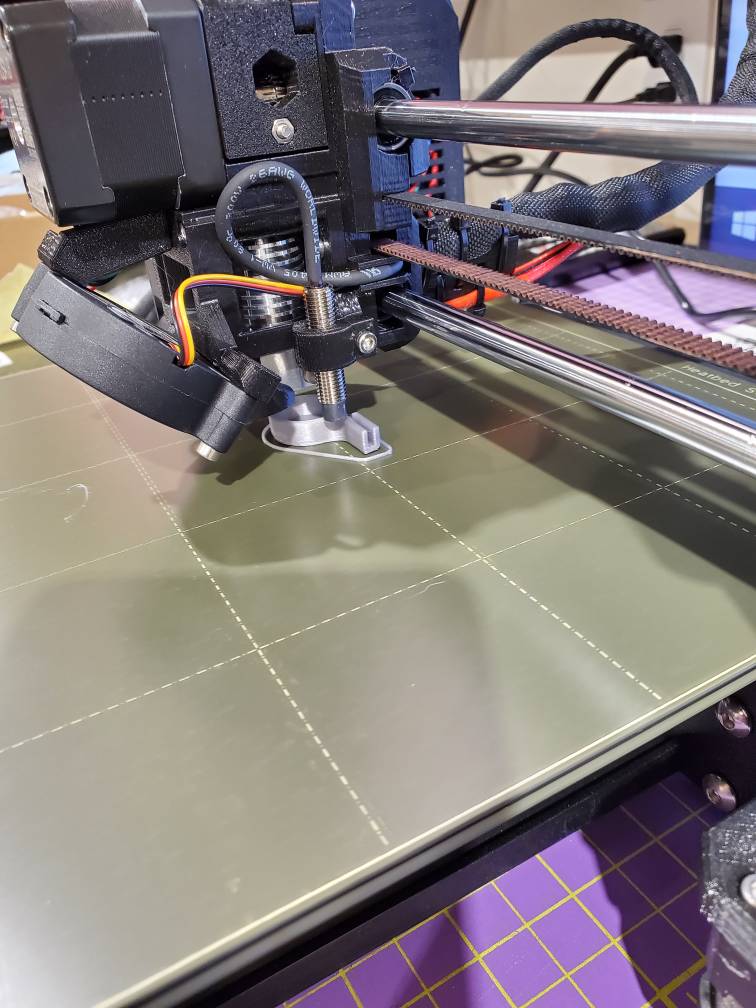

We bought our 13 year old one. He had some out of the box issues from the introductory model, but upgrades hardware. His latest accomplishment is a CV joint that he made for a remote controlled RC that had broken.

The possibilities are endless. Can you imagine just as a hobbyist being able to print parts for RC's on the go.

The possibilities are endless. Can you imagine just as a hobbyist being able to print parts for RC's on the go.

I would highly recommend watching some of the set up videos on YouTube before assembling, there are some additional steps recommended to help ensure things are square/level that aren't really covered in the instructions. I think we got somewhat lucky with ours that we didn't any of the common issues. I would assume this is true of all brands and not just Creality

^^good idea.

I've been reading their forums and picking up some info there.

Move on, nothing to see here.

I've been reading their forums and picking up some info there.

Move on, nothing to see here.

Got it put together. First print turned out ok. With a few minutes left, it came loose from the table. I'll have to look into that.

Move on, nothing to see here.

Move on, nothing to see here.

- Status

- Not open for further replies.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)