The following is an installation I performed for a customer among other installations which he would not like me to elaborate on as he plans on street racing this car. All you need to know is that it makes enough power to need a kit like this to even have a chance of hauling it back down to speed. 1996 Cobra convertible.

TCE offered my customer, as I do, a huge discount for military service. I would encourage you to order kits such as this through companies that have this policy. Keep in mind that the only reason you have the opportunity to modify your car as you see fit is because these guys get shot at for a job.

Unpackage the kit:

Read the directions. I consider myself an above average mechanic - ASE, Acura, and Ford Master Technician, diesel and SVT certifications working out of a full two car garage with ~$100K worth of tools and even I benefited by reading first.

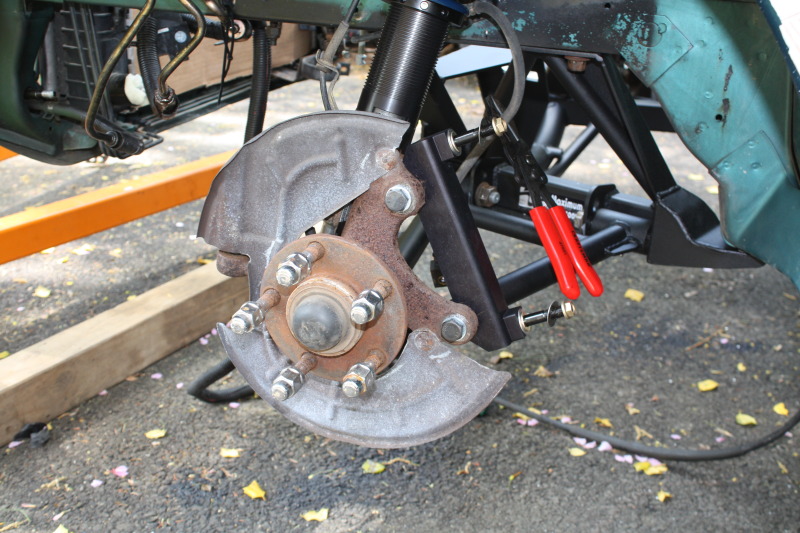

Begin by removing the wheel, stock caliper, caliper bracket, and rotor. If you need pictures up to this point, you should put the car back together and take it to a trained professional for the installation.

Install the radial bracket. They are not side specific. Install it in such an orientation that it puts the caliper farther forward, rather than farther inboard of the stock caliper bracket. NOTE: This was not part of the directions, and this picture is the INCORRECT way of installing which I figured out later.

This second, fuzzy picture is the correct orientation. The nut and bolt is 19mm or 3/4", and one large washer should be placed beneath the bolt head and the nut head.

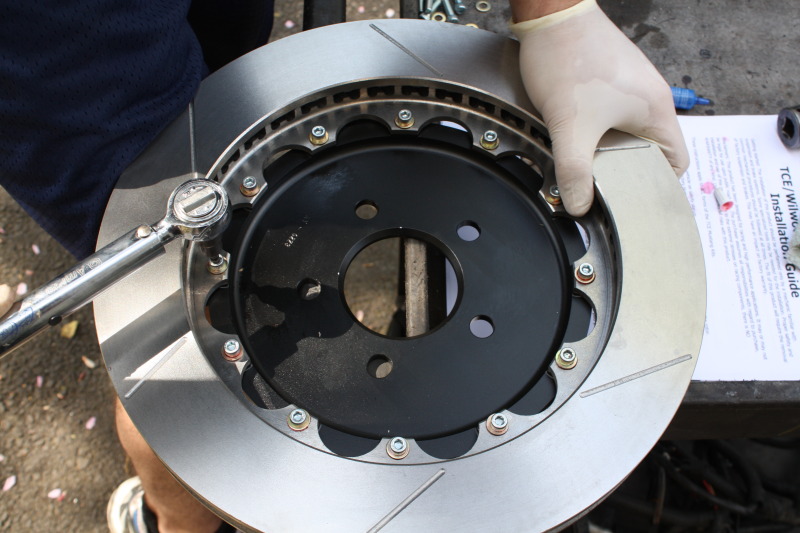

Flip the rotor over to the "back", then install the 12 allen headed bolts into each with washers underneath and red loctite. Not pictured, I put these in with my trusty electric impact gun to save time. The threads have paint/powdercoat on them, so they will offer some resistance. Start the first two directly across from each other to ensure you are aligned.

Torque to 14 ft/lb in a cross pattern

Install the rotor to the hub. Use two large nuts on two opposing lug studs, then install the lug nuts and torque to 100lb/ft.

Make absolutely sure the rotor sits completely flush to the hub face. Orient the rotor as pictured, then spin it. If there is any visible runout, take it off an examine. Some possible causes are:

rotor inner circle diameter is too tight to the hub

rotor inner lug stud diameter is too tight to the studs

buildup of rust, corrosion on the hub or studs

Since this car has seen the road a bit, on both sides I had to EXTENSIVELY clean the hub mating surface and enlarge the bores in the rotor center hole and lug stud holes

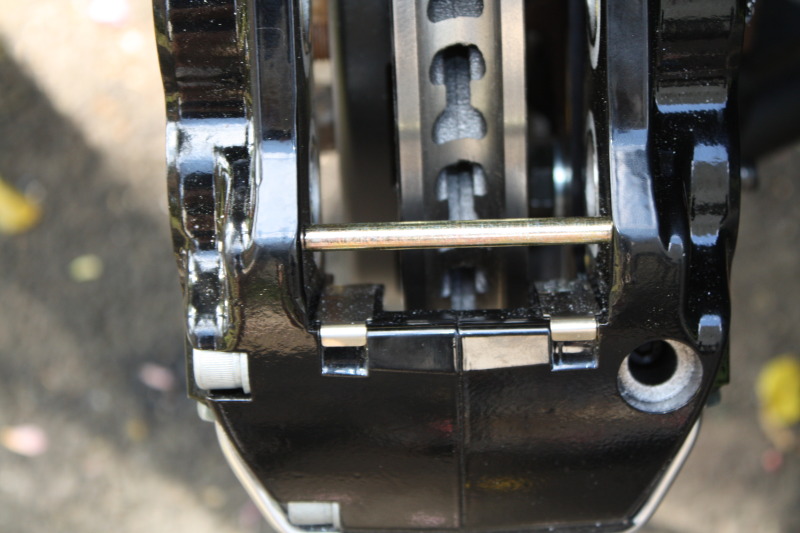

Install the caliper as a test fit. If it fits without hitting the rotor, spin the rotor again and ensure it is not wobbling side to side or touching the caliper at any point in revolution. This was my first test fit.

Remove the radial bracket, and install the .030" or .015" as needed to center the caliper on the rotor. If you are using a different spacer setup from top to bottom hole, you have a problem and need to go back to the rotor flush step.

When you are finally set up correctly, torque the two caliper to bracket bolts with a thin walled 13mm socket. Remove the pin retainers with a needle nose plier. Remove the pins, and install the top loading brake pads. Reinstall the pins, then reinstall the retainers with the same pliers.

Put a small bit of thread sealant on the NPT to AN fittings into the back of the caliper - 13mm open ended wrench.

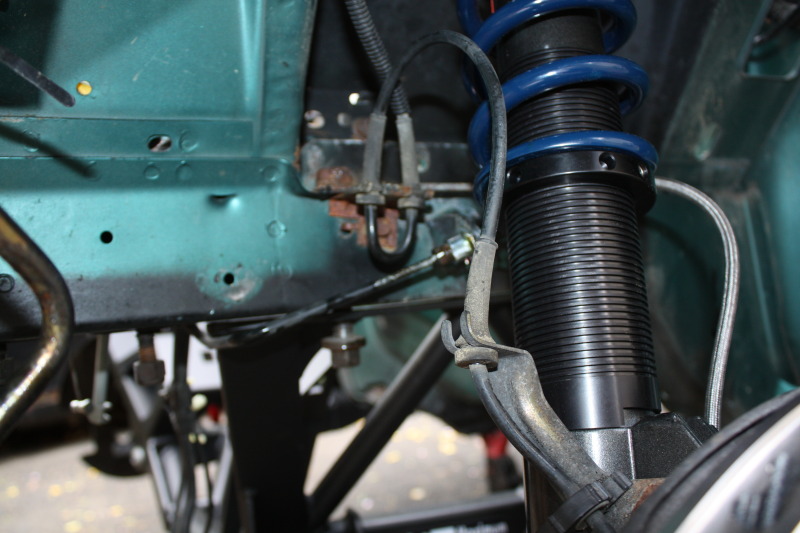

Select the appropriately sided brake line, and route it in such a way that it will not bind against the tire, coilover, or caliper.

At this point, use a 11mm open ended wrench to loosen the hardline to softline OEM connection. The needle nose plier will pull out the retaining clip. The supplied SS brake line will slide into place - thread it into the hardline before reinstalling the STOCK retainer clip, not the supplied one which fits loosely and poorly.

Bleed the brake system and reinstall the wheel - in the case of 14" rotor setup, 18" wheels are required.

Things I would like to see improved about the kit:

1. more specific directions, and pictures. I had to trial/error the orientation of the radial bracket, as well as the location of the washers.

2. the rotor hat - the tolerances for the lug studs were too tight for a realistically driven, rusted car. the tolerances for the center hole were too tight. the powdercoat/paint buildup in the threads was extreme and almost made it feel like you were cross-threading the ring-to-hub bolts. why could these have not been preassembled, loctite'd, and torqued?

3. I would like to see a larger, and LABELED, selection of shims. with only two choices, I had to settle on the best compromise and could visually estimate that the rotor was not perfectly centered on the caliper, though it was close.

4. instructions on how, and what type, of lubricant to put on the pads to avoid squeeling issues in the future.

Estimated time to completion:

first side - 2 hrs

second side - 30 minutes

TCE offered my customer, as I do, a huge discount for military service. I would encourage you to order kits such as this through companies that have this policy. Keep in mind that the only reason you have the opportunity to modify your car as you see fit is because these guys get shot at for a job.

Unpackage the kit:

Read the directions. I consider myself an above average mechanic - ASE, Acura, and Ford Master Technician, diesel and SVT certifications working out of a full two car garage with ~$100K worth of tools and even I benefited by reading first.

Begin by removing the wheel, stock caliper, caliper bracket, and rotor. If you need pictures up to this point, you should put the car back together and take it to a trained professional for the installation.

Install the radial bracket. They are not side specific. Install it in such an orientation that it puts the caliper farther forward, rather than farther inboard of the stock caliper bracket. NOTE: This was not part of the directions, and this picture is the INCORRECT way of installing which I figured out later.

This second, fuzzy picture is the correct orientation. The nut and bolt is 19mm or 3/4", and one large washer should be placed beneath the bolt head and the nut head.

Flip the rotor over to the "back", then install the 12 allen headed bolts into each with washers underneath and red loctite. Not pictured, I put these in with my trusty electric impact gun to save time. The threads have paint/powdercoat on them, so they will offer some resistance. Start the first two directly across from each other to ensure you are aligned.

Torque to 14 ft/lb in a cross pattern

Install the rotor to the hub. Use two large nuts on two opposing lug studs, then install the lug nuts and torque to 100lb/ft.

Make absolutely sure the rotor sits completely flush to the hub face. Orient the rotor as pictured, then spin it. If there is any visible runout, take it off an examine. Some possible causes are:

rotor inner circle diameter is too tight to the hub

rotor inner lug stud diameter is too tight to the studs

buildup of rust, corrosion on the hub or studs

Since this car has seen the road a bit, on both sides I had to EXTENSIVELY clean the hub mating surface and enlarge the bores in the rotor center hole and lug stud holes

Install the caliper as a test fit. If it fits without hitting the rotor, spin the rotor again and ensure it is not wobbling side to side or touching the caliper at any point in revolution. This was my first test fit.

Remove the radial bracket, and install the .030" or .015" as needed to center the caliper on the rotor. If you are using a different spacer setup from top to bottom hole, you have a problem and need to go back to the rotor flush step.

When you are finally set up correctly, torque the two caliper to bracket bolts with a thin walled 13mm socket. Remove the pin retainers with a needle nose plier. Remove the pins, and install the top loading brake pads. Reinstall the pins, then reinstall the retainers with the same pliers.

Put a small bit of thread sealant on the NPT to AN fittings into the back of the caliper - 13mm open ended wrench.

Select the appropriately sided brake line, and route it in such a way that it will not bind against the tire, coilover, or caliper.

At this point, use a 11mm open ended wrench to loosen the hardline to softline OEM connection. The needle nose plier will pull out the retaining clip. The supplied SS brake line will slide into place - thread it into the hardline before reinstalling the STOCK retainer clip, not the supplied one which fits loosely and poorly.

Bleed the brake system and reinstall the wheel - in the case of 14" rotor setup, 18" wheels are required.

Things I would like to see improved about the kit:

1. more specific directions, and pictures. I had to trial/error the orientation of the radial bracket, as well as the location of the washers.

2. the rotor hat - the tolerances for the lug studs were too tight for a realistically driven, rusted car. the tolerances for the center hole were too tight. the powdercoat/paint buildup in the threads was extreme and almost made it feel like you were cross-threading the ring-to-hub bolts. why could these have not been preassembled, loctite'd, and torqued?

3. I would like to see a larger, and LABELED, selection of shims. with only two choices, I had to settle on the best compromise and could visually estimate that the rotor was not perfectly centered on the caliper, though it was close.

4. instructions on how, and what type, of lubricant to put on the pads to avoid squeeling issues in the future.

Estimated time to completion:

first side - 2 hrs

second side - 30 minutes