Recently, I installed a Spec 3+ clutch and a Fidanza flywheel (about 2k miles ago). Well the Spec Throwout bearing went out on me so I purchased a FRPP TOB and did the swap in my garage. After doing some research on here, it appears im not the only one with TOB issues so I thought I would document the steps needed to replace it on your own. Access to a lift would make the job A LOT easier, however in reality most of us do work to our Cobras in our own garage. Here it goes.....

1st remove the (-) negative battery terminal (8mm).

Next, inside the car, remove the shifter ball along with the bezel and attached shifter boot. The bezel is snapped into place so just gently pull up on it to remove it.

At this time you can dis-connect the lighter connector behind the bezel.

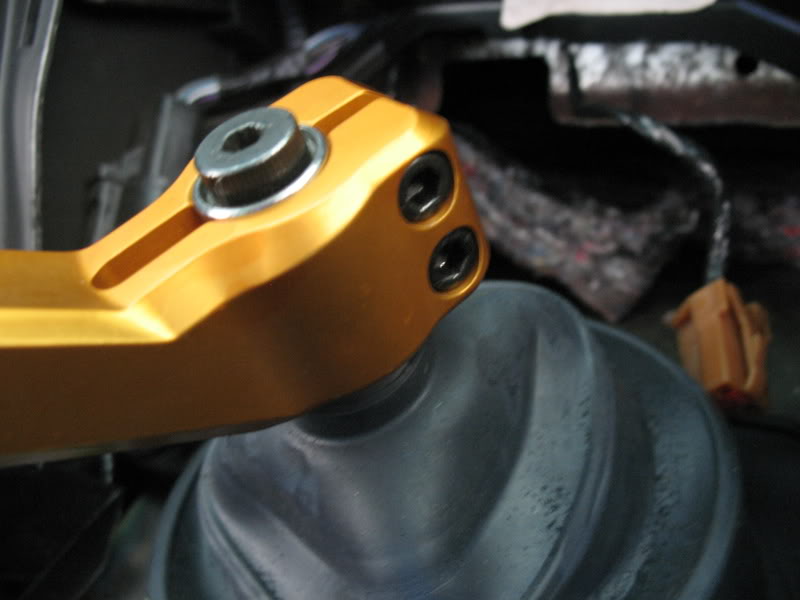

Now, remove the shifter handle. My car is equipped with an MGW so all I had to do was loosen the 2 allen head bolts to remove the handle.

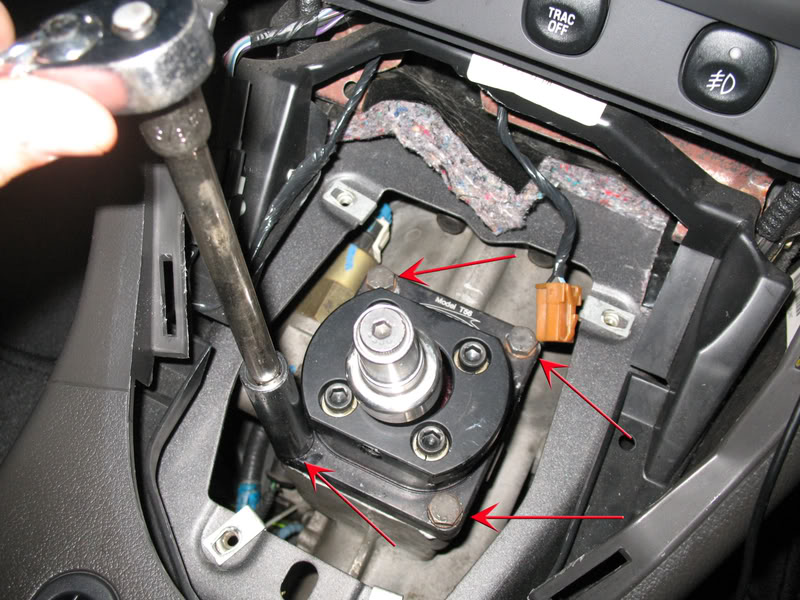

Next, remove the four bolts holding the shiter cover to gain access to the shifter bolts themselves.

Now we can remove the shifter by removing the 4 mounting bolts to the transmission. Once the bolts are out you may have to "wiggle" it to free it from the transmission. This is normal.

With the shifter removed now is a good time to disconnect this plug! Access is limited once your underneath the car.

Safely raise the car and place jack stands on all 4 corners of the car. Take time doing this and get it as high off the ground as safely as possible!! I have subframe connectors which is a VERY good spot to support your car with jack stands.

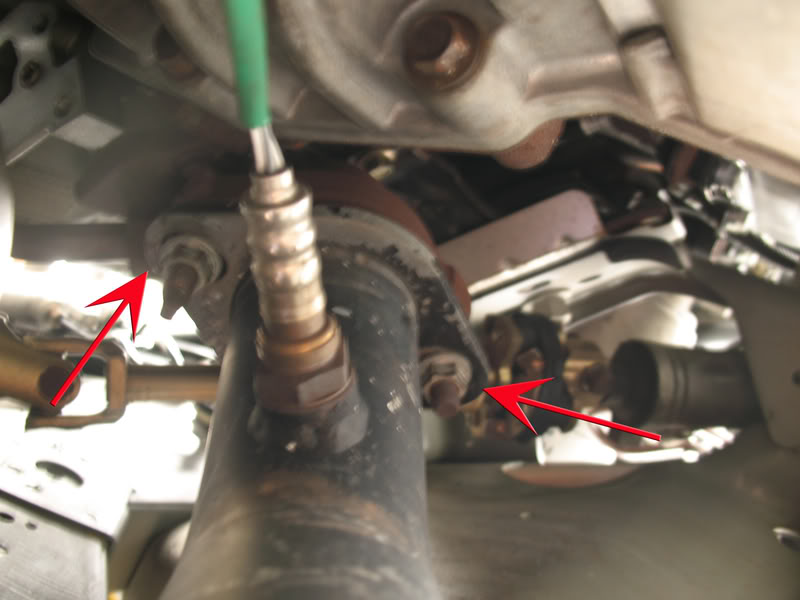

Now, begin removing the mid pipe. Every application will be slightly different but remove the necessary bolts/nuts to remove it and place it off to the side.

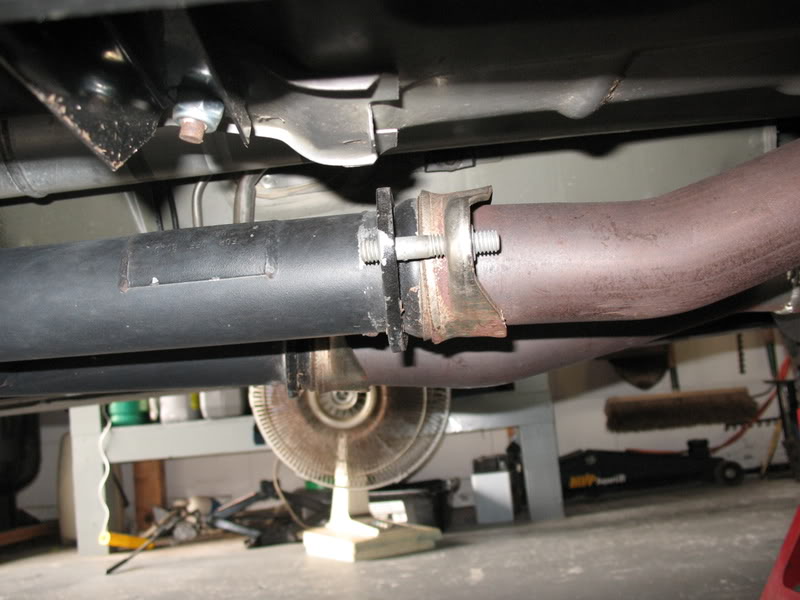

With the mid-pipe out of the way we will remove the driveshaft from the car. BEFORE REMOVING ANY BOLTS FROM THE DRIVESHAFT use a marker and mark the position of the driveshaft and ensure it gets re-installed in the same position. Once you have placed your mark(s) (as shown) remove the 4 12mm 12 point bolts from the driveshaft and remove it. Once again, you may have to tap on the driveshaft with a rubber mallet to free it from the rear end. (this is normal)

At this time you should not loose any fluid out of the transmission tail shaft, however, in the next steps, fluid may begin to come out. You have 2 options. Let the fluid drain into a pan, or place a GOOD quality plastic bag over the tail shaft and secure it with many rubber bands to prevent it from leaking. Thats what I did and it worked very well!

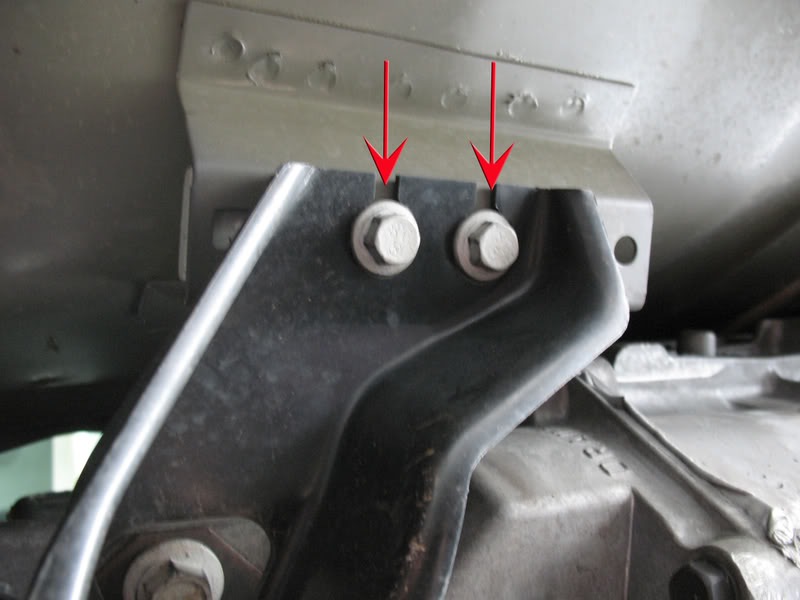

You can now remove the four transmission cross member bolts on either side and set them aside. (note: The transmission will slightly drop when removing these bolts)

Disconnect any harnesses that are attached to the trans and tuck them away in a safe place to prevent them from being snagged.

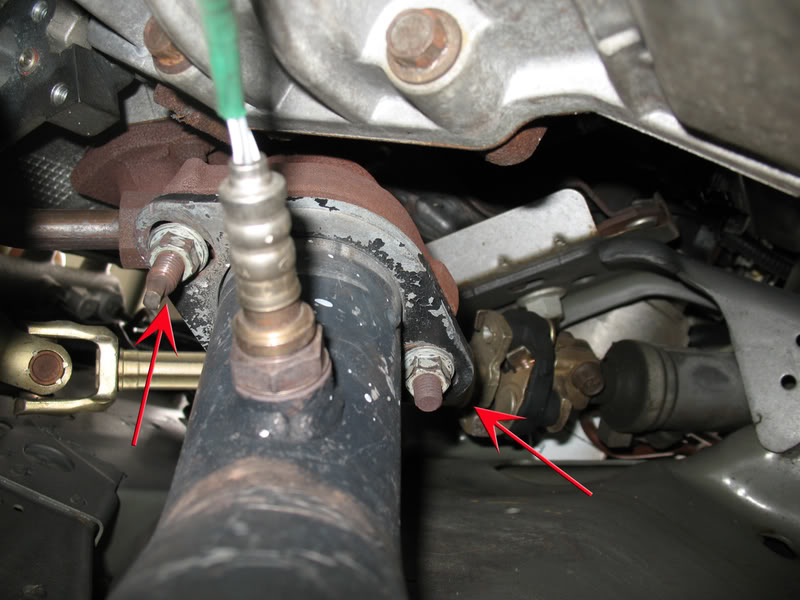

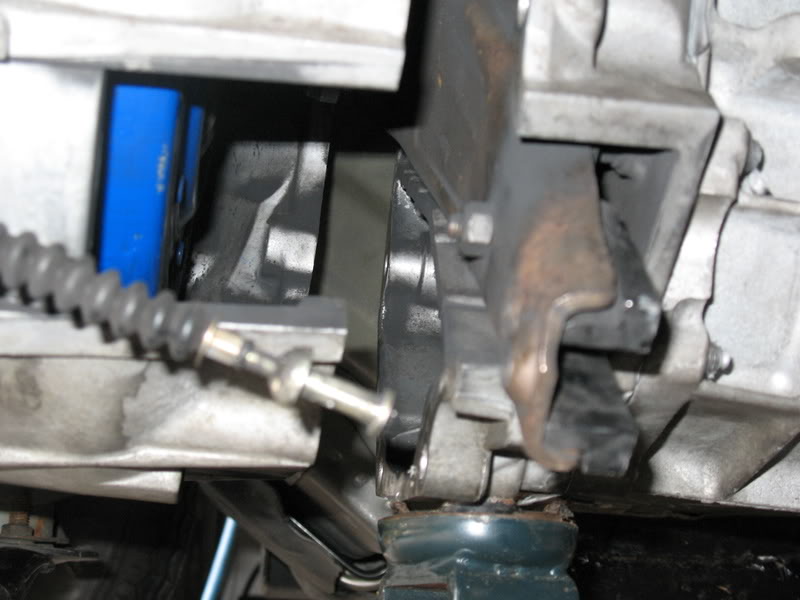

Now, remove the inspection shield to gain access to the clutch cable

With the inspection shield removed, we can now disconnect the clutch cable from the clutch fork. Using a flat headed screw driver, pry on the cable to dislodge it from the mounting slot in the clutch fork.

We can now begin to remove the 8 15mm bolts holding the transmission to the belhousing. Now is a good time to support the front and rear with jacks to prevent the transmission from moving to much.

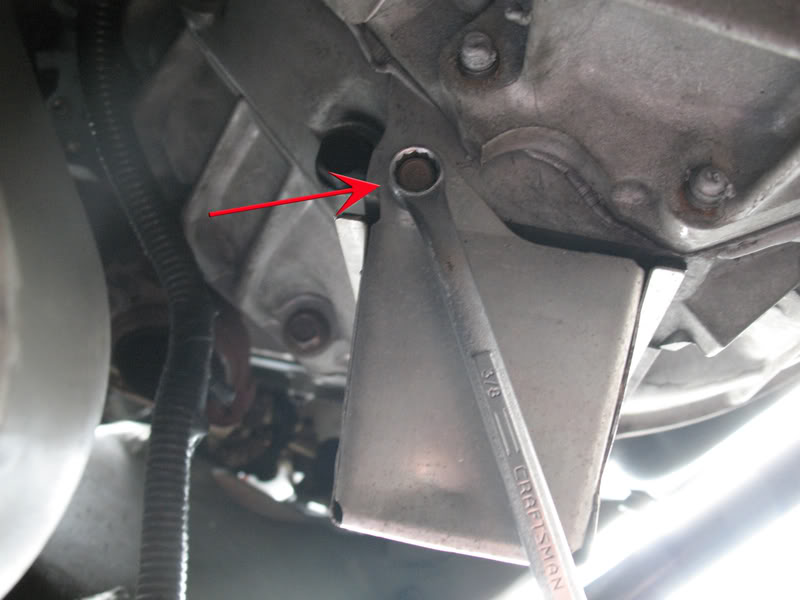

There is one bolt, commonly referred to as the "bitch" bolt. It is one of the 8 bolts holding the trans to the bell housing and it is located on the top passenger side of the transmission. This bolt is in fact a pain in the a$$ but with a little patience and LONG extensions/swivel heads it will come out.

Once all 8 transmission bolts are removed, the transmission is ready to come out. 2 or more people will be needed to help with this. I was by myself so while I waited on a few friends, I took a beer break!

With the help of friends, safely pull back on the trans to pull the input shaft out of the clutch and lower the transmission onto the ground. I placed it on a 4 wheel dolly which made it easy to roll around on.

With your right hand on the clutch fork, give it a firm pull towards you, to disconnect the clip from the ball stud.

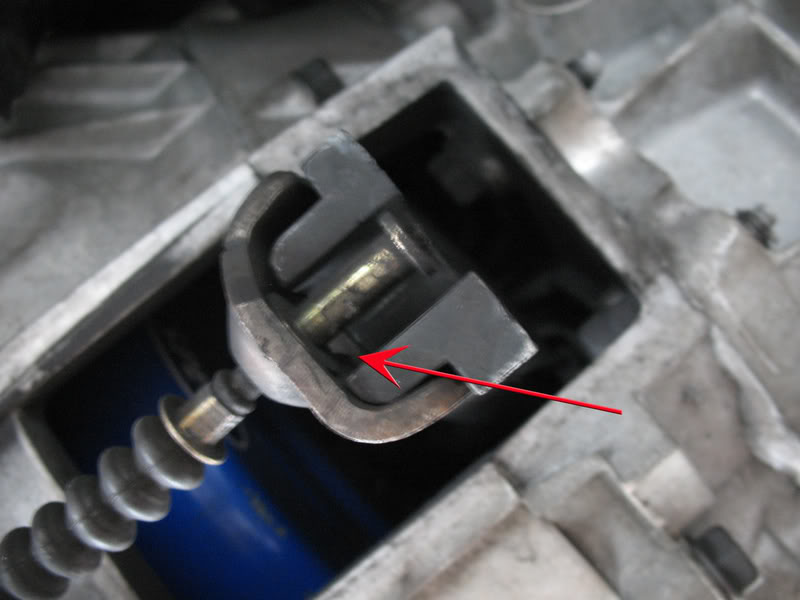

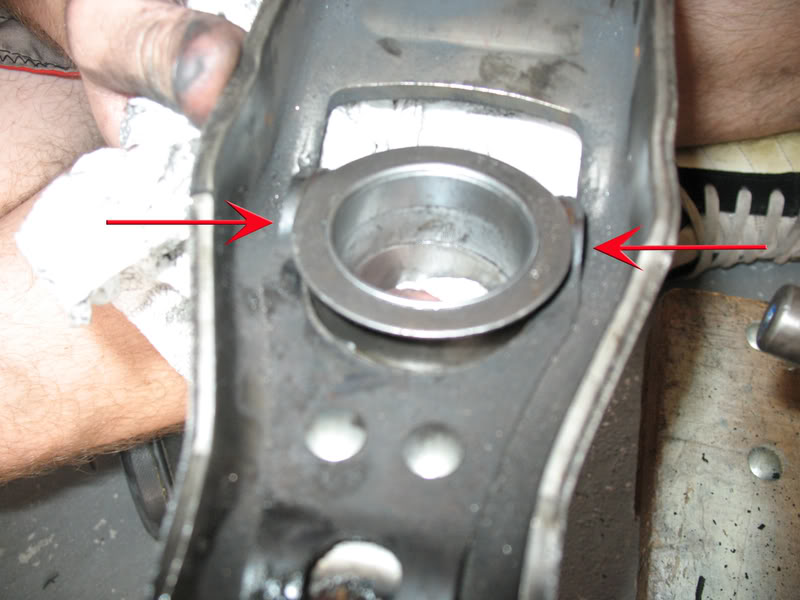

Remove the old TOB and install the new bearing onto the clutch fork as shown. Make sure the bearing is installed on the TOP of the clips like shown in the picture

Before re-installing the clutch fork, check the bearing retainer for any dirt/debris and make sure there are no gouges and the retainer is clean. DO NOT APPLY GREASE TO THE RETAINER!!! Only apply grease to the ball stud!

Once your clutch fork is back into position, make sure your able to move the clutch fork with ease and there is no binding.

Now all thats left to do is reverse the steps and re-install the transmission. As a side not, Remember to re-install the driveshaft in the same position as it was. Line up your marks and USE loctite on the 4 bolts when re-installing the driveshaft!

Good luck and I hope this was helpful. :beer:

1st remove the (-) negative battery terminal (8mm).

Next, inside the car, remove the shifter ball along with the bezel and attached shifter boot. The bezel is snapped into place so just gently pull up on it to remove it.

At this time you can dis-connect the lighter connector behind the bezel.

Now, remove the shifter handle. My car is equipped with an MGW so all I had to do was loosen the 2 allen head bolts to remove the handle.

Next, remove the four bolts holding the shiter cover to gain access to the shifter bolts themselves.

Now we can remove the shifter by removing the 4 mounting bolts to the transmission. Once the bolts are out you may have to "wiggle" it to free it from the transmission. This is normal.

With the shifter removed now is a good time to disconnect this plug! Access is limited once your underneath the car.

Safely raise the car and place jack stands on all 4 corners of the car. Take time doing this and get it as high off the ground as safely as possible!! I have subframe connectors which is a VERY good spot to support your car with jack stands.

Now, begin removing the mid pipe. Every application will be slightly different but remove the necessary bolts/nuts to remove it and place it off to the side.

With the mid-pipe out of the way we will remove the driveshaft from the car. BEFORE REMOVING ANY BOLTS FROM THE DRIVESHAFT use a marker and mark the position of the driveshaft and ensure it gets re-installed in the same position. Once you have placed your mark(s) (as shown) remove the 4 12mm 12 point bolts from the driveshaft and remove it. Once again, you may have to tap on the driveshaft with a rubber mallet to free it from the rear end. (this is normal)

At this time you should not loose any fluid out of the transmission tail shaft, however, in the next steps, fluid may begin to come out. You have 2 options. Let the fluid drain into a pan, or place a GOOD quality plastic bag over the tail shaft and secure it with many rubber bands to prevent it from leaking. Thats what I did and it worked very well!

You can now remove the four transmission cross member bolts on either side and set them aside. (note: The transmission will slightly drop when removing these bolts)

Disconnect any harnesses that are attached to the trans and tuck them away in a safe place to prevent them from being snagged.

Now, remove the inspection shield to gain access to the clutch cable

With the inspection shield removed, we can now disconnect the clutch cable from the clutch fork. Using a flat headed screw driver, pry on the cable to dislodge it from the mounting slot in the clutch fork.

We can now begin to remove the 8 15mm bolts holding the transmission to the belhousing. Now is a good time to support the front and rear with jacks to prevent the transmission from moving to much.

There is one bolt, commonly referred to as the "bitch" bolt. It is one of the 8 bolts holding the trans to the bell housing and it is located on the top passenger side of the transmission. This bolt is in fact a pain in the a$$ but with a little patience and LONG extensions/swivel heads it will come out.

Once all 8 transmission bolts are removed, the transmission is ready to come out. 2 or more people will be needed to help with this. I was by myself so while I waited on a few friends, I took a beer break!

With the help of friends, safely pull back on the trans to pull the input shaft out of the clutch and lower the transmission onto the ground. I placed it on a 4 wheel dolly which made it easy to roll around on.

With your right hand on the clutch fork, give it a firm pull towards you, to disconnect the clip from the ball stud.

Remove the old TOB and install the new bearing onto the clutch fork as shown. Make sure the bearing is installed on the TOP of the clips like shown in the picture

Before re-installing the clutch fork, check the bearing retainer for any dirt/debris and make sure there are no gouges and the retainer is clean. DO NOT APPLY GREASE TO THE RETAINER!!! Only apply grease to the ball stud!

Once your clutch fork is back into position, make sure your able to move the clutch fork with ease and there is no binding.

Now all thats left to do is reverse the steps and re-install the transmission. As a side not, Remember to re-install the driveshaft in the same position as it was. Line up your marks and USE loctite on the 4 bolts when re-installing the driveshaft!

Good luck and I hope this was helpful. :beer: