fairly new to the turbo side and currently building an auto twin turbo car with a fully built stroker boss block 9.5:1. been looking into either the precision 6466 or 6766 but get lost when it comes to AR's. any input or experience is greatly appreciated. car will be stand alone as well and currently looking into the haltec or proefi units. looking to make over 1200 to the wheels.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to pick AR for 1000+ twin turbo 4v?

- Thread starter 00saleens281

- Start date

I would look into Borg Warner also. Give Work Turbochargers and Forced Inductions a call. They will each get you set up with the right turbos.

Look into the Holley EFI as well. Join the Mod Motor W/Holley EFI group on FaceBook for lots of great info and base tune file to work from.

Look into the Holley EFI as well. Join the Mod Motor W/Holley EFI group on FaceBook for lots of great info and base tune file to work from.

I would look into Borg Warner also. Give Work Turbochargers and Forced Inductions a call. They will each get you set up with the right turbos.

Look into the Holley EFI as well. Join the Mod Motor W/Holley EFI group on FaceBook for lots of great info and base tune file to work from.

just requested to join the group on FB. i will look into those turbos as well. another one i was looking into were bullseye since the guy building my car has told me about them and friends with him.

drag but will be turned down for occasional street use.

I went with comp turbo ct4 62/65's, .70 a/r, triple ball bearing, divided flange.

Even with stage 3 cams and stage 3 ported ford gt/gt500 heads (cavernous, 375cfm@~.500 lift), anywhere above 4000rpm, I get 9-10psi within half a second.

I'm making 720whp on 9psi as well. I was going to upload a video of the spool but it keeps saying the source (my camera reel on my iPhone) isn't a safe source.

Basically, if I'm above 4K rpms, and floor it, I have 9-10psi in a quarter of a second or less it feels like.

I'm running 3.73 rear, manual t56, and hyper aggressive heads and cams for a street car. .70 a/r is perfect for twins on a modular seeing 6750-7500rpm.

If you plan to run 6000-7250rpm, maybe a .58-.62 a/r.

Even with stage 3 cams and stage 3 ported ford gt/gt500 heads (cavernous, 375cfm@~.500 lift), anywhere above 4000rpm, I get 9-10psi within half a second.

I'm making 720whp on 9psi as well. I was going to upload a video of the spool but it keeps saying the source (my camera reel on my iPhone) isn't a safe source.

Basically, if I'm above 4K rpms, and floor it, I have 9-10psi in a quarter of a second or less it feels like.

I'm running 3.73 rear, manual t56, and hyper aggressive heads and cams for a street car. .70 a/r is perfect for twins on a modular seeing 6750-7500rpm.

If you plan to run 6000-7250rpm, maybe a .58-.62 a/r.

The car is a mainly race car, I wouldn't go under .082 A/R on the exhaust. No one I know makes a .70 A/R exhaust housing, that's usually the compressor housing size.

Race or street, the rpm range, displacement, turbo size and driving characteristics are what will matter. If the goal is power production at xyz rpm, spec the a/r accordingly.

Obviously we are talking about area ratio relative to the compressor wheel.

If the op will need the car to run strong from 7000-9000rpm, then yes, a .83 a/r, or possibly even .88 a/r (or what the turbo manufacturer has closest to those values) is a great choice.

Op, what will you rev this engine to, and what rear ratio, tire height, and auto will you be running?

Take those numbers, calculate your rpm range per gear, and tailer your a/r accordingly.

Example:

28" tire

4.10 rear

th400

8000rpm

Running a .83 is an excellent choice because you'll be between 7100-8000rpm most of the strip.

28" tire

4.56

C4

9200rpm

Running a larger .88 a/r makes sense because you'll be between roughly 7700-9200rpm most of the strip.

26" tire

3.73

4r70w

7500rpm

A .70 ar is great because this is a street car setup that likes 6000-7500rpm.

26" tire

3.55

4r70w

6500rpm

.60 ar is great.

Ar is area ratio. Discharge relative to compresser opening. The closer/larger than 1:1 you go, the more rpm needed to reach optimal flow.

A 12,000 rpm cbr1000 will run a 1.5+ a/r.

A 5000rpm stock turbo car will run a tiny .30-.50 a/r.

There's plenty of good YouTube videos that explain the science, and the way to calculate what you'll need.

Obviously we are talking about area ratio relative to the compressor wheel.

If the op will need the car to run strong from 7000-9000rpm, then yes, a .83 a/r, or possibly even .88 a/r (or what the turbo manufacturer has closest to those values) is a great choice.

Op, what will you rev this engine to, and what rear ratio, tire height, and auto will you be running?

Take those numbers, calculate your rpm range per gear, and tailer your a/r accordingly.

Example:

28" tire

4.10 rear

th400

8000rpm

Running a .83 is an excellent choice because you'll be between 7100-8000rpm most of the strip.

28" tire

4.56

C4

9200rpm

Running a larger .88 a/r makes sense because you'll be between roughly 7700-9200rpm most of the strip.

26" tire

3.73

4r70w

7500rpm

A .70 ar is great because this is a street car setup that likes 6000-7500rpm.

26" tire

3.55

4r70w

6500rpm

.60 ar is great.

Ar is area ratio. Discharge relative to compresser opening. The closer/larger than 1:1 you go, the more rpm needed to reach optimal flow.

A 12,000 rpm cbr1000 will run a 1.5+ a/r.

A 5000rpm stock turbo car will run a tiny .30-.50 a/r.

There's plenty of good YouTube videos that explain the science, and the way to calculate what you'll need.

I went with comp turbo ct4 62/65's, .70 a/r, triple ball bearing, divided flange.

Even with stage 3 cams and stage 3 ported ford gt/gt500 heads (cavernous, 375cfm@~.500 lift), anywhere above 4000rpm, I get 9-10psi within half a second.

I'm making 720whp on 9psi as well. I was going to upload a video of the spool but it keeps saying the source (my camera reel on my iPhone) isn't a safe source.

Basically, if I'm above 4K rpms, and floor it, I have 9-10psi in a quarter of a second or less it feels like.

I'm running 3.73 rear, manual t56, and hyper aggressive heads and cams for a street car. .70 a/r is perfect for twins on a modular seeing 6750-7500rpm.

If you plan to run 6000-7250rpm, maybe a .58-.62 a/r.

How does your FR-500C perform in the upper RPM? Worried about mine holding back RPM.

Edit: I use twin 62/74's with .96 ar's. I used a smaller turbo with larger AR to keep the exhaust side smooth allowing me to run a much larger more aggressive cam with more overlap than allowed with a exhaust restricted setup.

Race or street, the rpm range, displacement, turbo size and driving characteristics are what will matter. If the goal is power production at xyz rpm, spec the a/r accordingly.

Obviously we are talking about area ratio relative to the compressor wheel.

If the op will need the car to run strong from 7000-9000rpm, then yes, a .83 a/r, or possibly even .88 a/r (or what the turbo manufacturer has closest to those values) is a great choice.

Op, what will you rev this engine to, and what rear ratio, tire height, and auto will you be running?

Take those numbers, calculate your rpm range per gear, and tailer your a/r accordingly.

Example:

28" tire

4.10 rear

th400

8000rpm

Running a .83 is an excellent choice because you'll be between 7100-8000rpm most of the strip.

28" tire

4.56

C4

9200rpm

Running a larger .88 a/r makes sense because you'll be between roughly 7700-9200rpm most of the strip.

26" tire

3.73

4r70w

7500rpm

A .70 ar is great because this is a street car setup that likes 6000-7500rpm.

26" tire

3.55

4r70w

6500rpm

.60 ar is great.

Ar is area ratio. Discharge relative to compresser opening. The closer/larger than 1:1 you go, the more rpm needed to reach optimal flow.

A 12,000 rpm cbr1000 will run a 1.5+ a/r.

A 5000rpm stock turbo car will run a tiny .30-.50 a/r.

There's plenty of good YouTube videos that explain the science, and the way to calculate what you'll need.

thank you for the info.

its a stroker 323ci 5.3L boss block. L&M fully built with their custom cams.

28" tire

3.73 currently

4r70w

7500-8000rpm depending where it makes power to.

planning on having Lund racing tune it

Upper rpm power is almost flat but slowly gains. Very happy with the fr500c so far. I'm running the normal plumes, but I could fit the 3/4" shorter ones if I wanted even more top end. It won't match a Sullivan for peak power, but if I had a Sullivan on my current combo it would be very laggy.

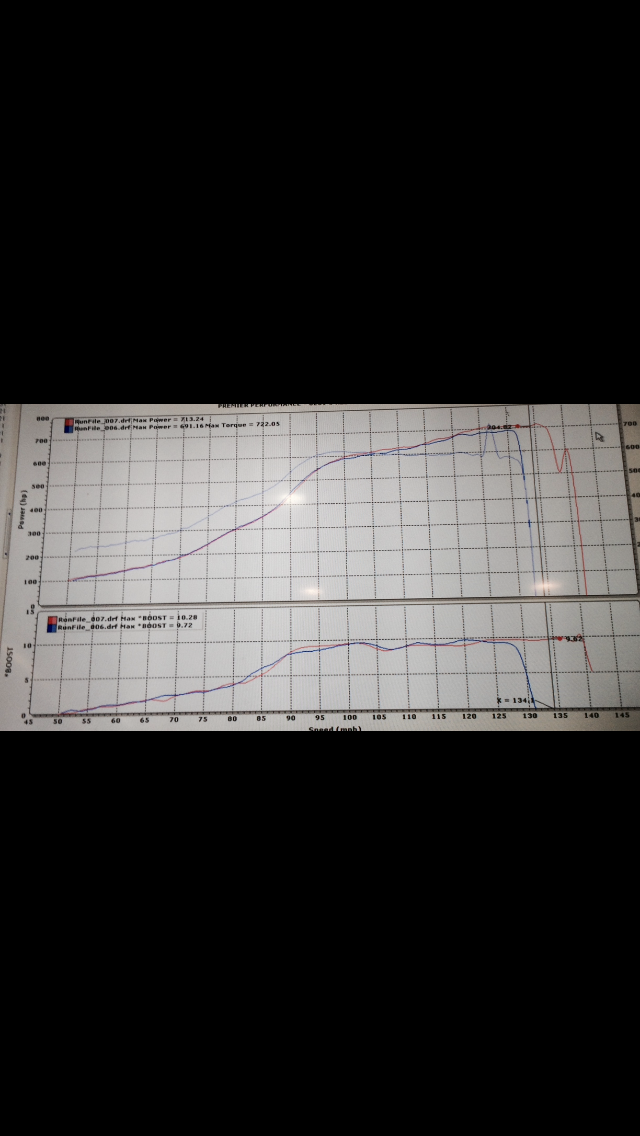

I'll attach an old dyno from a break in tune that was only spun to 6700rpm. We're now working on 12-30psi tunes and 7500-8000rpm.

To the op, if you plan to keep redline rpm to 8000rpms, anything from a .70-.83 will work nicely. The .83 will complement 7000-8000 better, but the .70 won't be far behind, yet it will likely spool noticeably faster. 4r70w gearing is

1. 2.84

2. 1.55

3. 1.00

4. .70

Using Wallace racings calculator, you'll click 62mph in 1st at 8k and drop to about 4300rpm in second, reach 115mph, drop to about 5500rpm in 3rd, and reach 178mph at 8000rpm.

If you get 1200whp to hook and book a 1.2 60ft in a 2750-2900lbs car, you'd be about a 175mph trap speed so the 3.73 is great, but I'd run a .70 a/r. You're spending tons of time below 7000-8000rpm.

If you had a 6r80e 6spd auto and 4.10's with 28" tires and the same engine, the. A .83 ar makes sense.

I haven't built a 4r70w car with 1200whp and just running the numbers, I don't know how robust it would be with that kind of load.

Another option if trap speed is closer to 155mph and you end up running a safer 800-1000whp is to step to a 4.30 rear. With a 4.30, you'll drop to about 4750rpm 1-2, 6000rpm 2-3. At that point, something like a .75-.80 ar starts to make sense since you'll be about half the time above 7000rpm.

I'll attach an old dyno from a break in tune that was only spun to 6700rpm. We're now working on 12-30psi tunes and 7500-8000rpm.

To the op, if you plan to keep redline rpm to 8000rpms, anything from a .70-.83 will work nicely. The .83 will complement 7000-8000 better, but the .70 won't be far behind, yet it will likely spool noticeably faster. 4r70w gearing is

1. 2.84

2. 1.55

3. 1.00

4. .70

Using Wallace racings calculator, you'll click 62mph in 1st at 8k and drop to about 4300rpm in second, reach 115mph, drop to about 5500rpm in 3rd, and reach 178mph at 8000rpm.

If you get 1200whp to hook and book a 1.2 60ft in a 2750-2900lbs car, you'd be about a 175mph trap speed so the 3.73 is great, but I'd run a .70 a/r. You're spending tons of time below 7000-8000rpm.

If you had a 6r80e 6spd auto and 4.10's with 28" tires and the same engine, the. A .83 ar makes sense.

I haven't built a 4r70w car with 1200whp and just running the numbers, I don't know how robust it would be with that kind of load.

Another option if trap speed is closer to 155mph and you end up running a safer 800-1000whp is to step to a 4.30 rear. With a 4.30, you'll drop to about 4750rpm 1-2, 6000rpm 2-3. At that point, something like a .75-.80 ar starts to make sense since you'll be about half the time above 7000rpm.

Break in tune on 9psi with 12* of timing, and 6700rpm. We've picked up torque and spool characteristics since this dyno run. The fr500c isn't too soft up top though. I'll rarely run much over 7500rpm. My t56 won't shift much past 7300.

I've removed the trumpets and rounded the attachment points to give it the shortest runners possible. Aiming for 1200-1300rwhp and 7500 rpm.

To OP: Your cam selection will have a large amount to do with your A/R.

To OP: Your cam selection will have a large amount to do with your A/R.

Nice work nightmare302, I was contemplating doing so as well.

I street drive the car so I like the torque production the fr500c offers between 2500-6500 with the longer plumes.

I've made 720whp on 9psi so I'm pretty confident it'll reach 1200+ on 25-30psi. My guestimation is my na mill is making 450whp based on what we've seen with 9psi. I just don't think I'll need to go too custom with the fr500c to make my power goals. If it falls short, I'll have a back up plan though.

I street drive the car so I like the torque production the fr500c offers between 2500-6500 with the longer plumes.

I've made 720whp on 9psi so I'm pretty confident it'll reach 1200+ on 25-30psi. My guestimation is my na mill is making 450whp based on what we've seen with 9psi. I just don't think I'll need to go too custom with the fr500c to make my power goals. If it falls short, I'll have a back up plan though.

Upper rpm power is almost flat but slowly gains. Very happy with the fr500c so far. I'm running the normal plumes, but I could fit the 3/4" shorter ones if I wanted even more top end. It won't match a Sullivan for peak power, but if I had a Sullivan on my current combo it would be very laggy.

I'll attach an old dyno from a break in tune that was only spun to 6700rpm. We're now working on 12-30psi tunes and 7500-8000rpm.

To the op, if you plan to keep redline rpm to 8000rpms, anything from a .70-.83 will work nicely. The .83 will complement 7000-8000 better, but the .70 won't be far behind, yet it will likely spool noticeably faster. 4r70w gearing is

1. 2.84

2. 1.55

3. 1.00

4. .70

Using Wallace racings calculator, you'll click 62mph in 1st at 8k and drop to about 4300rpm in second, reach 115mph, drop to about 5500rpm in 3rd, and reach 178mph at 8000rpm.

If you get 1200whp to hook and book a 1.2 60ft in a 2750-2900lbs car, you'd be about a 175mph trap speed so the 3.73 is great, but I'd run a .70 a/r. You're spending tons of time below 7000-8000rpm.

If you had a 6r80e 6spd auto and 4.10's with 28" tires and the same engine, the. A .83 ar makes sense.

I haven't built a 4r70w car with 1200whp and just running the numbers, I don't know how robust it would be with that kind of load.

Another option if trap speed is closer to 155mph and you end up running a safer 800-1000whp is to step to a 4.30 rear. With a 4.30, you'll drop to about 4750rpm 1-2, 6000rpm 2-3. At that point, something like a .75-.80 ar starts to make sense since you'll be about half the time above 7000rpm.

Wouldn't these calculations be off, consider it does not factor in converter slip? I used a calculator when I went th400 that showed 7000 rpm to be 164mph. However, I crossed the traps around 7300 and my best mph was 154. I realize that trap speed isnt exact, and likely was a tad higher, but it was still off a good bit.

Converter slip is problematic, but the major reason that such calculators don't seem accurate is because a tire grow in size by the big end of the track.

About 2" of growth to be honest (stretching really).

So if you had a 28" tire, it's going to grow about an inch ever 75mph rough. At 150mph, it's about a 30" tall tire.

If you redo calculations with 30" (assuming your calculating trap speed) it'll be bang on.

Converter slip is a factor in the 1/8th and 1/16th for sure, but by the 1/4, and beyond its usually pretty well locked and loaded.

About 2" of growth to be honest (stretching really).

So if you had a 28" tire, it's going to grow about an inch ever 75mph rough. At 150mph, it's about a 30" tall tire.

If you redo calculations with 30" (assuming your calculating trap speed) it'll be bang on.

Converter slip is a factor in the 1/8th and 1/16th for sure, but by the 1/4, and beyond its usually pretty well locked and loaded.

Nice work nightmare302, I was contemplating doing so as well.

I street drive the car so I like the torque production the fr500c offers between 2500-6500 with the longer plumes.

I've made 720whp on 9psi so I'm pretty confident it'll reach 1200+ on 25-30psi. My guestimation is my na mill is making 450whp based on what we've seen with 9psi. I just don't think I'll need to go too custom with the fr500c to make my power goals. If it falls short, I'll have a back up plan though.

Interesting guess. I'm running the Fr500 intake I put down just under 460rwhp with the switchover flaps removed and the top plate modded for a SVO big oval TB. So your 450rwhp is right on the money. I just posted a thread and I'm thinking about running a single gtx4508R as it seems like the map will match my build perfectly.

5.3L 4v ported heads and custom cams my dyno pull made 450rwhp+ from 6300ish rpm too 7500ish. It was flat HP from there on so we didn't wind it out any further.

Last edited:

Nice work nightmare302, I was contemplating doing so as well.

I street drive the car so I like the torque production the fr500c offers between 2500-6500 with the longer plumes.

I've made 720whp on 9psi so I'm pretty confident it'll reach 1200+ on 25-30psi. My guestimation is my na mill is making 450whp based on what we've seen with 9psi. I just don't think I'll need to go too custom with the fr500c to make my power goals. If it falls short, I'll have a back up plan though.

My tq came in at 300+ at about 2500 and pulled 300+ till the pull stopped at 7500 and it peaked right around 390ish at the usual 5250 mark.

Interesting I was just doing the calcs and figured about 8psi would give me roughly 830ish flwhp fuel limited at this point.

Converter slip is problematic, but the major reason that such calculators don't seem accurate is because a tire grow in size by the big end of the track.

About 2" of growth to be honest (stretching really).

So if you had a 28" tire, it's going to grow about an inch ever 75mph rough. At 150mph, it's about a 30" tall tire.

If you redo calculations with 30" (assuming your calculating trap speed) it'll be bang on.

Converter slip is a factor in the 1/8th and 1/16th for sure, but by the 1/4, and beyond its usually pretty well locked and loaded.

Are you suggesting that even radial tires will grow that far? I have not heard of such (which means absolutely nothing) .. also, converter slip would still have to be a factor in something like a th400 where there is no lock up, correct?

I will also be running a Sullivan lower with an 90 elbow, possibly a Wilson or a 6061.

PTE makes the 6466 turbos in a .68 and .81 AR or divided in a .84 AR.

i thought turbos like longer gear ratios for the load and with an auto once you shift to 2nd wouldn't the power be different since the turbos are already spooled and don't loose boost as compared with a stick?

PTE makes the 6466 turbos in a .68 and .81 AR or divided in a .84 AR.

i thought turbos like longer gear ratios for the load and with an auto once you shift to 2nd wouldn't the power be different since the turbos are already spooled and don't loose boost as compared with a stick?

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)