I've had the Aeroforce Interceptor Gauge for a while now and I absolutely love it! When I purchased it, I also bought one of the oil pressure kits to use with one of the Interceptros two analog inputs since oil pressure isn't read through the computer. I finally got around to installing the oil pressure kit and here's how it went...

These are the items that came with the kit...

The harness with the 3 black wires is for the pressure sender and the other harness with the colored wires plugs into the back of the Interceptor. The WHITE wire is Analog 2 and the GREEN wire is Analog 1. The red wire isn't used since the Interceptor gets it's power from the OBDII port on Ford applications...

This is the 0-100 PSI AC Delco pressure sender that came with the kit...

This sender calls for a 5V power source. Initially, I didn't know of a 5V power source on the truck so I bought a voltage reducer from Lew. But I ended up finding out through one of Fade 2 Black's How-To's that the EGR power wire is 5V. So I used it instead of the reducer. Here's what the reducer looks like...

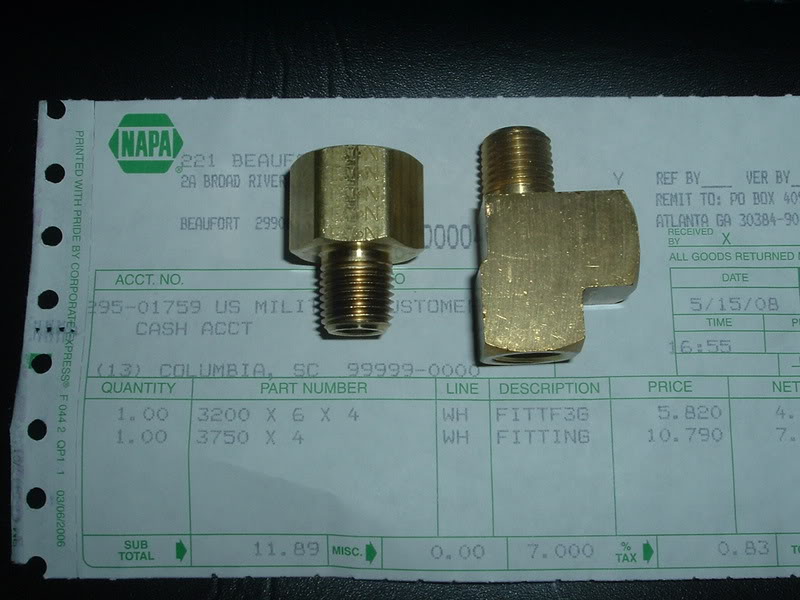

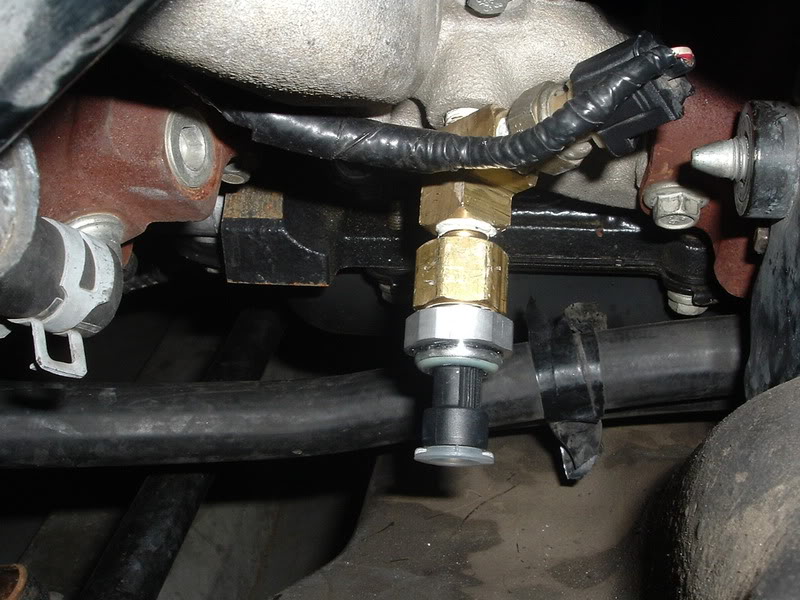

I had to buy some fittings from NAPA in order to adapt this sender to my Lightning. The stock oil sender/switch is 1/4" NPT and the AC Delco sender is 3/8". I wanted to retain the stock switch so here's the fittings I got. The fitting on the left is a 1/4" Male - 3/8" Female reducer fitting and the one on the right is a 1/4" Male X 1/4" Female X 1/4" Female 90 degree fitting.

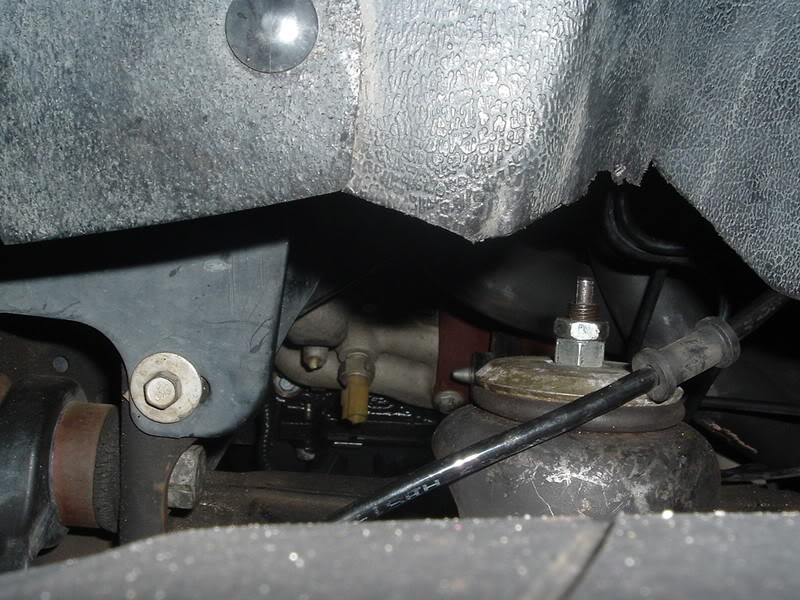

Here's a couple pics from the drivers side front fender well that'll help you locate the stock sender switch...

Once I unplugged the harness, I used a 13/16" socket to remove the stock switch...

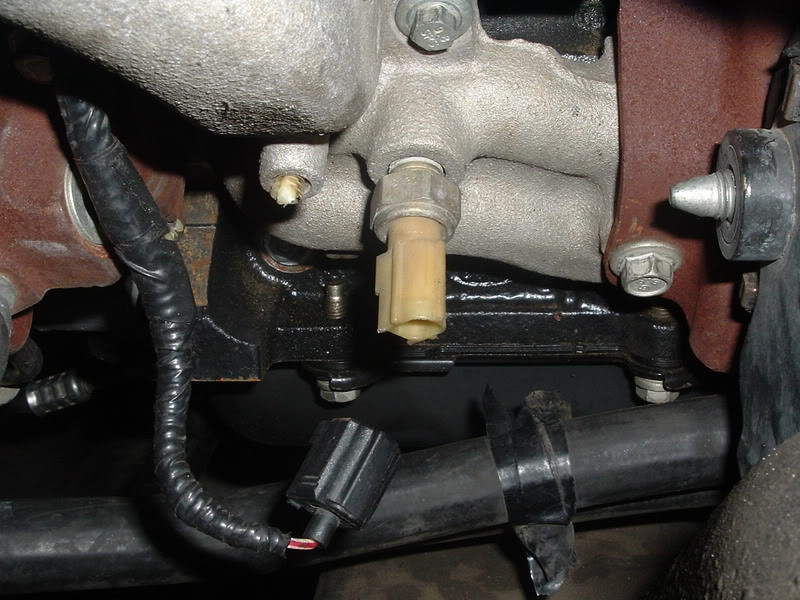

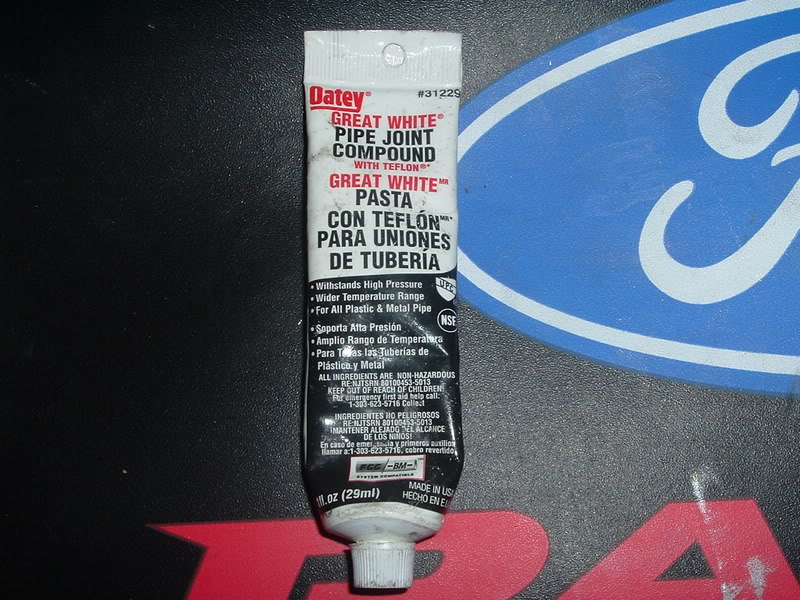

Then I applied some pipe joint compound to the threads of the 90 degree fitting and used an adjustable wrench to install it...

Then I applied some pipe joint compound to the threads of the AC Delco sender and used a 27MM socket on the sender and an adjustable wrench on the 1/4" - 3/8" reducer fitting to fit them together...

Then I applied some pipe joint compound to the threads of the 1/4" male end of the reducer fitting and the stock switch and installed them into the 90 degree fitting. I could have installed the senders differently, but this will work...

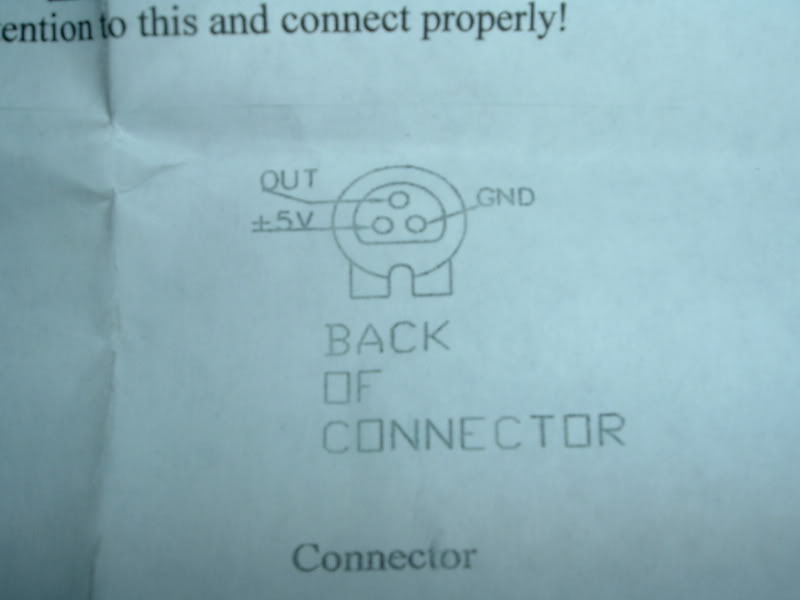

Next I had to wire everything up. I started with the harness for the AC Delco sender. Here's a diagram that came with it from AI that explains what each wire is...

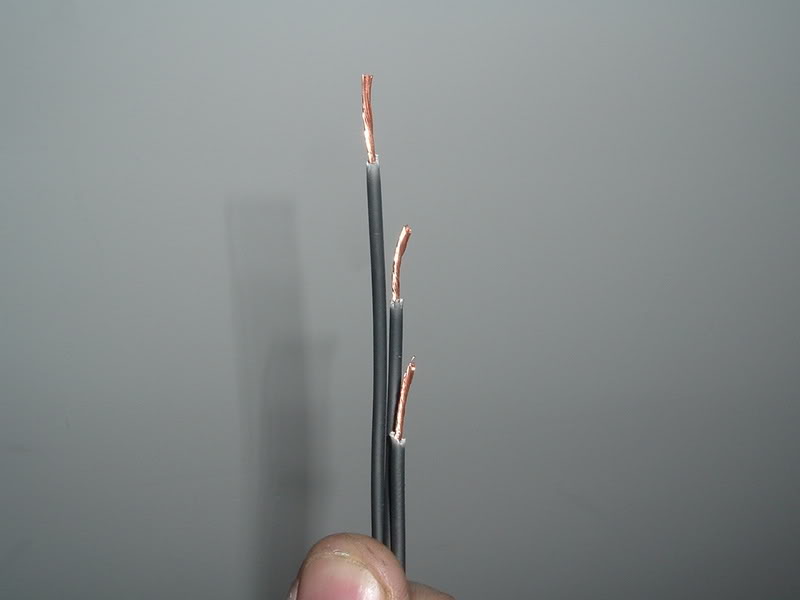

I cut the harness wires at different length so they would fit in the convoluted tubing I planned to put around them better. This way there won't be a bulge in one spot...

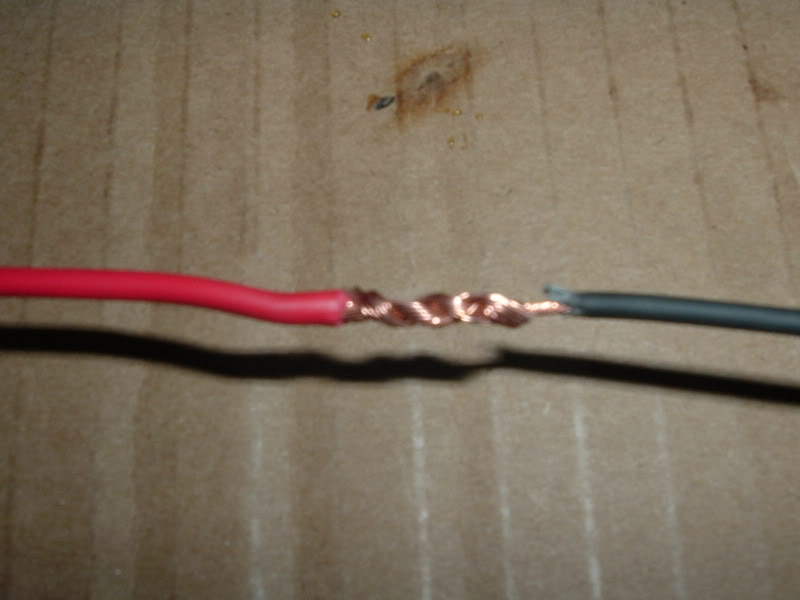

Next I cut some long sections of wire for the harness. I cut them extra long just in case. It's better to start with a longer wire than realizing later you didn't use enough. I used RED for the power, BLACK for the ground and BLACK for the signal. I just cut a little longer piece of black for the signal so I wouldn't get it confused with the ground. I soldered all of these wires together and used heat shrink tubing to cover them...

Here's my little tackle box with some of my wiring supplies and the heat gun I got from Summit a while ago...

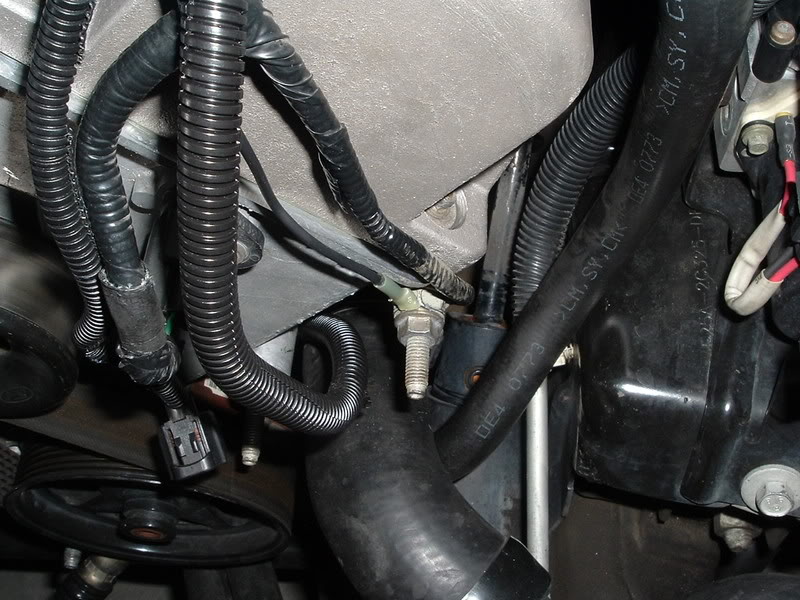

Then I surrounded the wires with some convoluted tubing and ran them up to the top of the engine. I followed the same path as the wires for the stock switch and used tie-wraps to secure them together. The first wire I worked on was the sender ground. I used a ring connector and grounded it to one of the studs that secures the chain cover to the block...

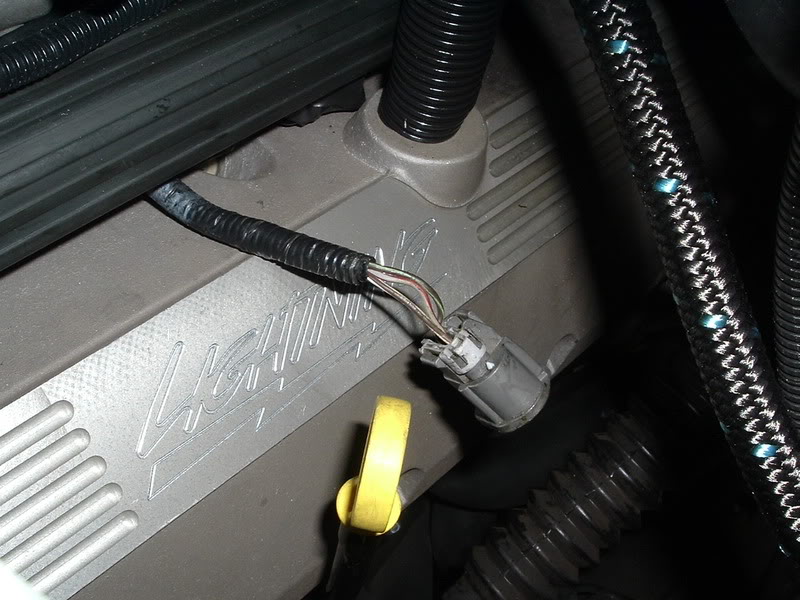

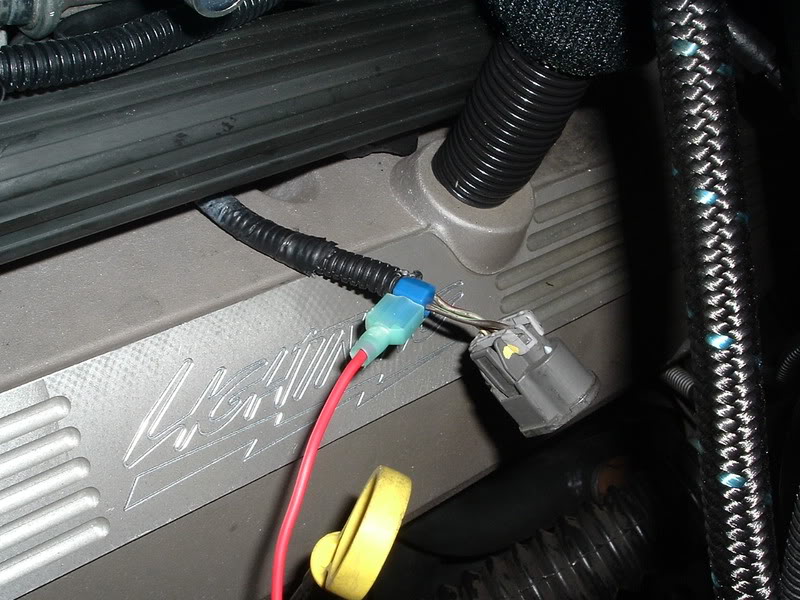

Next I found my power source. I used a Multi-Meter to find which wire I needed on the EGR harness. There are three wires for this harness and both of the outside wires read 5V. But I found out when I initially tried to set everything up that one must be a falling signal because the one I tapped into was reading negative 9-something on the Interceptor. So I switched to the other outside wire and it worked fine...

Next I needed to get the last wire, the signal wire, to the Interceptor. I went into the cab through the large grommet on the fire wall. I had previously ran several wires through this location so I just pushed this one through...

I pulled the kick panel out so I would have better access and ran the signal wire up to the Interceptor. I tie-wrapped this wire to the Interceptors harness cable just to keep them together...

Next, I had to connect this wire to the harness I mentioned earlier. I decided to use Analog 2 (WHITE wire) which is the LEFT pin on the back of the Interceptor. So I connected the signal wire I ran up to the gauge to the WHITE wire of the harness and plugged it into the Interceptor. Then I re-installed the Interceptor back into my gauge pod...

Then I wanted to make sure everything worked before I put the cab back together and hid the wires under the hood. The kit also came with instruction on programming the Interceptor for this sender. These instructions are extremely clear but I'll list the steps to program the Interceptor anyway...

1. Turn the key forward to power-up the Interceptor.

2. Push both buttons on the face of Interceptor at the same time. This takes you to the MENU.

3. Push the LEFT button and scroll through the menu until to get to "Analog 2" and push the right button to select it. (I used Analog 2 but you can use Analog 1 if you want)

4. You'll then be able to enter the conversion. The first setting that will pop up is "SLOPE". Enter 031.9 for this setting. Use the left button to change the numbers and the right button to move onto the next number. Once you're done with the last number, push the right button again to be taken to the next setting to modify.

5. The next setting is "INTERCEPT". Set this value to -09.7. The negative sign needs to be entered in the first position on the left, so it will look like "-09.7". Once you're done with the last number, push the right button again.

6. You'll be taken to the Analog Menu where you can select what you want this Analog to be called. Use the left button to scroll through the menu and the right button to select the name you want. There are several different names on this menu such as; Analog 1, Analog 2, Air Fuel, Fuel Pressure, Oil Pressure, Fluid Temperature, EGT, and a few others that I can't remember right now. I just installed an Oil Pressure Kit, so naturally I chose Oil Pressure. Once you've selected the name, scroll through the menu with the left button until you come to "EXIT".

7. Press the right button and you'll be taken back to the main menu. Select "SCAN" and you're good to go!

I started up my engine to check everything out and I was seeing 79-80 PSI of oil pressure. This seems normal since the engine was cold and I have a Melling High Volume Oil Pump. Then I buttoned everything up and called it a day.

These are the items that came with the kit...

The harness with the 3 black wires is for the pressure sender and the other harness with the colored wires plugs into the back of the Interceptor. The WHITE wire is Analog 2 and the GREEN wire is Analog 1. The red wire isn't used since the Interceptor gets it's power from the OBDII port on Ford applications...

This is the 0-100 PSI AC Delco pressure sender that came with the kit...

This sender calls for a 5V power source. Initially, I didn't know of a 5V power source on the truck so I bought a voltage reducer from Lew. But I ended up finding out through one of Fade 2 Black's How-To's that the EGR power wire is 5V. So I used it instead of the reducer. Here's what the reducer looks like...

I had to buy some fittings from NAPA in order to adapt this sender to my Lightning. The stock oil sender/switch is 1/4" NPT and the AC Delco sender is 3/8". I wanted to retain the stock switch so here's the fittings I got. The fitting on the left is a 1/4" Male - 3/8" Female reducer fitting and the one on the right is a 1/4" Male X 1/4" Female X 1/4" Female 90 degree fitting.

Here's a couple pics from the drivers side front fender well that'll help you locate the stock sender switch...

Once I unplugged the harness, I used a 13/16" socket to remove the stock switch...

Then I applied some pipe joint compound to the threads of the 90 degree fitting and used an adjustable wrench to install it...

Then I applied some pipe joint compound to the threads of the AC Delco sender and used a 27MM socket on the sender and an adjustable wrench on the 1/4" - 3/8" reducer fitting to fit them together...

Then I applied some pipe joint compound to the threads of the 1/4" male end of the reducer fitting and the stock switch and installed them into the 90 degree fitting. I could have installed the senders differently, but this will work...

Next I had to wire everything up. I started with the harness for the AC Delco sender. Here's a diagram that came with it from AI that explains what each wire is...

I cut the harness wires at different length so they would fit in the convoluted tubing I planned to put around them better. This way there won't be a bulge in one spot...

Next I cut some long sections of wire for the harness. I cut them extra long just in case. It's better to start with a longer wire than realizing later you didn't use enough. I used RED for the power, BLACK for the ground and BLACK for the signal. I just cut a little longer piece of black for the signal so I wouldn't get it confused with the ground. I soldered all of these wires together and used heat shrink tubing to cover them...

Here's my little tackle box with some of my wiring supplies and the heat gun I got from Summit a while ago...

Then I surrounded the wires with some convoluted tubing and ran them up to the top of the engine. I followed the same path as the wires for the stock switch and used tie-wraps to secure them together. The first wire I worked on was the sender ground. I used a ring connector and grounded it to one of the studs that secures the chain cover to the block...

Next I found my power source. I used a Multi-Meter to find which wire I needed on the EGR harness. There are three wires for this harness and both of the outside wires read 5V. But I found out when I initially tried to set everything up that one must be a falling signal because the one I tapped into was reading negative 9-something on the Interceptor. So I switched to the other outside wire and it worked fine...

Next I needed to get the last wire, the signal wire, to the Interceptor. I went into the cab through the large grommet on the fire wall. I had previously ran several wires through this location so I just pushed this one through...

I pulled the kick panel out so I would have better access and ran the signal wire up to the Interceptor. I tie-wrapped this wire to the Interceptors harness cable just to keep them together...

Next, I had to connect this wire to the harness I mentioned earlier. I decided to use Analog 2 (WHITE wire) which is the LEFT pin on the back of the Interceptor. So I connected the signal wire I ran up to the gauge to the WHITE wire of the harness and plugged it into the Interceptor. Then I re-installed the Interceptor back into my gauge pod...

Then I wanted to make sure everything worked before I put the cab back together and hid the wires under the hood. The kit also came with instruction on programming the Interceptor for this sender. These instructions are extremely clear but I'll list the steps to program the Interceptor anyway...

1. Turn the key forward to power-up the Interceptor.

2. Push both buttons on the face of Interceptor at the same time. This takes you to the MENU.

3. Push the LEFT button and scroll through the menu until to get to "Analog 2" and push the right button to select it. (I used Analog 2 but you can use Analog 1 if you want)

4. You'll then be able to enter the conversion. The first setting that will pop up is "SLOPE". Enter 031.9 for this setting. Use the left button to change the numbers and the right button to move onto the next number. Once you're done with the last number, push the right button again to be taken to the next setting to modify.

5. The next setting is "INTERCEPT". Set this value to -09.7. The negative sign needs to be entered in the first position on the left, so it will look like "-09.7". Once you're done with the last number, push the right button again.

6. You'll be taken to the Analog Menu where you can select what you want this Analog to be called. Use the left button to scroll through the menu and the right button to select the name you want. There are several different names on this menu such as; Analog 1, Analog 2, Air Fuel, Fuel Pressure, Oil Pressure, Fluid Temperature, EGT, and a few others that I can't remember right now. I just installed an Oil Pressure Kit, so naturally I chose Oil Pressure. Once you've selected the name, scroll through the menu with the left button until you come to "EXIT".

7. Press the right button and you'll be taken back to the main menu. Select "SCAN" and you're good to go!

I started up my engine to check everything out and I was seeing 79-80 PSI of oil pressure. This seems normal since the engine was cold and I have a Melling High Volume Oil Pump. Then I buttoned everything up and called it a day.