i dont know if people have posted this before, but i thought this saved a lot of work.

im in the process of assembling my motor and thought this was pretty neat. its an easy way to keep you imrcs wide open.

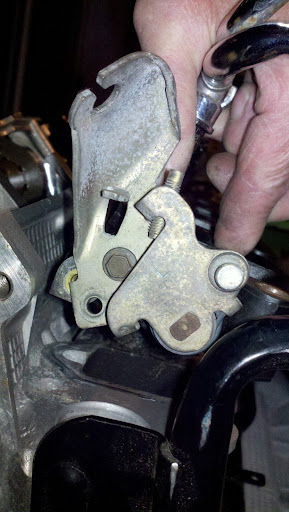

this is what a regular imrc looks like from the rear:

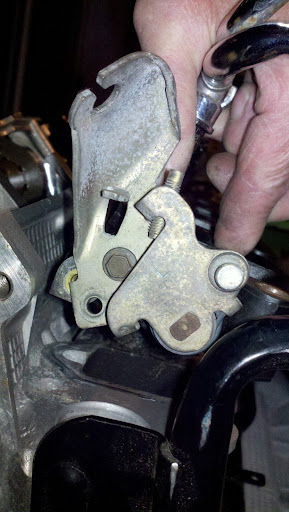

and a regular imrc at wide open notice the stop on the cable mount:

loosen the two 8mm bolts as seen here:

reposition the imrc blade wheel behind the cable mount stop so that the stop actually holds the imrcs open:

in the works:

repositioned:

finished product:

enjoy your now open imrcs (dont forget your tune!). no deletes needed, no jb weld. im doing this with the motor in my sunroom, but it may be possible with the motor and intake manifold still in the car. hope this makes sense.

im in the process of assembling my motor and thought this was pretty neat. its an easy way to keep you imrcs wide open.

this is what a regular imrc looks like from the rear:

and a regular imrc at wide open notice the stop on the cable mount:

loosen the two 8mm bolts as seen here:

reposition the imrc blade wheel behind the cable mount stop so that the stop actually holds the imrcs open:

in the works:

repositioned:

finished product:

enjoy your now open imrcs (dont forget your tune!). no deletes needed, no jb weld. im doing this with the motor in my sunroom, but it may be possible with the motor and intake manifold still in the car. hope this makes sense.