Looking at the wear and tear on those bushings I have to wonder what kind of punishment the solid mount lowers are doing to the internals.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bringing the 4lb Caged lower back from the Dead?

- Thread starter cj428mach

- Start date

Here what I found after disassembly.

All 3 bushings were split.

All depends on your setup. Here's my bushings after 400 miles.

Pretty destroyed

That was with a 2.9 Whipple spinning the heck out of it with a high compression motor that wraps up and down RPMs extremely rapidly compare to stock (very crisp throttle response). I switched to the schedule 80 I think it was. It's black and feels rock hard compare to that rubber.

What Mike supplies is very comparable to stock and should work for the majority of people. If you have issues you can upgrade the rubber.

Hey guys,

Got an update with my 4lb lower.

I had noticed my tribar wasnt sitting in the middle of the bushing material anymore.

I removed the lower to look at it better and noticed the bushing material is actually being torn apart.

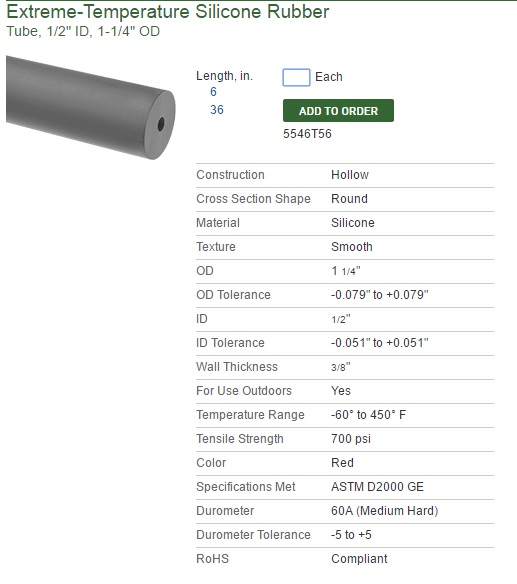

I looked up the part number that we have and the specs are below.

I think the 700 psi rating may be too low for the pressure it gets from the rotating of the engine.

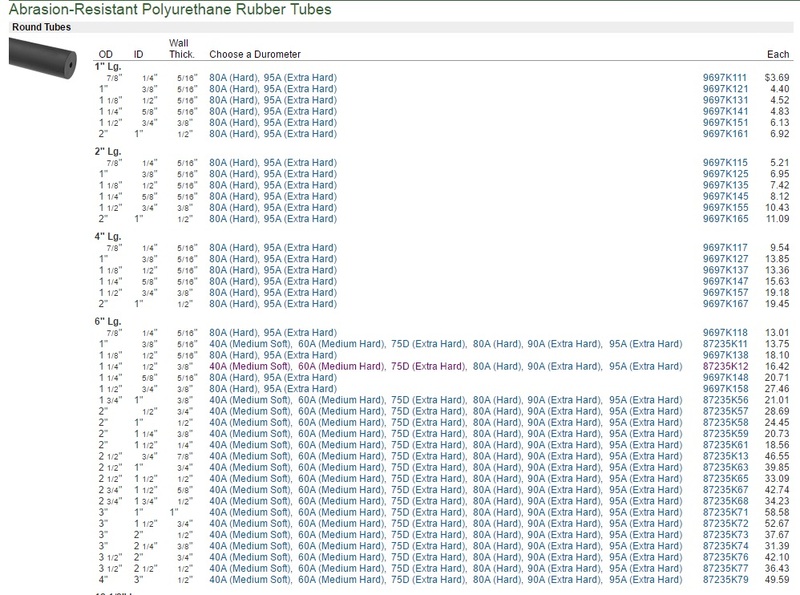

I looked up other material tubing and found a polyurethane tubing that comes in 40A(2000psi) 60A(4400psi) 75d(7500psi).

Part number is 87235K12 on mcmaster carr.

I ordered 6 inches of each to see what might be best.

The only thing you give up is the original material is rated to 450 degrees F where this material is rated to 200 degrees F.

I installed the new bushing material. The 40A was very soft. The 75D is super hard, only way I could compress it was in a vise. I went with the 60A. I have around 300 miles on it now and looks perfect.

If the 60A doesnt work out (i think it will work fine) I will probably try to run the 75D.

Dam, I think I'm gonna hold off on installing my lower. Thanks for sharing guys.

My setup is a 2.9 crusher on 24 lbs right now. I have long tubes, stage 3 cams, and the 4 lb lower sitting in my garage ready to go come Winter. Planning to tear the motor down again and do flat tops with valve reliefs and some billet I beams.

I'm a little skeptical of the bushing material now. Either that or it will need to be replaced frequently since my car is 95% track only.

My setup is a 2.9 crusher on 24 lbs right now. I have long tubes, stage 3 cams, and the 4 lb lower sitting in my garage ready to go come Winter. Planning to tear the motor down again and do flat tops with valve reliefs and some billet I beams.

I'm a little skeptical of the bushing material now. Either that or it will need to be replaced frequently since my car is 95% track only.

So today was the day I really tested the 60A bushing material. Had a huge car meet with a lot of horsing around(launching, powershifting). After all day the bushing material looks just as new. I completely recommend the 60A material.

Also after some research the 75"D" (d is for hard rubber). So that is why it is pretty much solid.

I might order some 80"A"(a is for flexible rubber) to see how that works

Also after some research the 75"D" (d is for hard rubber). So that is why it is pretty much solid.

I might order some 80"A"(a is for flexible rubber) to see how that works

Last edited:

Im interested in a idler if still available to go with my setup. Also you have a part number on the new rubber material you can pm me? Thanks

Anyone have one of these for sale?

Sent from my SM-G930V using Tapatalk

Sent from my SM-G930V using Tapatalk

Im interested in a idler if still available to go with my setup. Also you have a part number on the new rubber material you can pm me? Thanks

I know its a long thread but all your answers are in the thread, I don't have them committed to memory so I'd have to dig through the thread myself. I posted the silicone part numbers and Rymax posted a harder bushing material.

As for the idlers they're all gone, I don't have anymore. There are also several options for idlers that are shown in the thread.

I'm still running the 63mm metco idler and silicone bushings. At over 2500 miles later my setup is still as good as the day I put it on.

Last edited:

CJ428 you sold out of these right?

I still have the 60a in my lower and they still look like new. I have the 80a in the garage for a back up but don't know if it will be required but when I upgrade my blower I may upgrade the bushingsRymax how those upgraded bushings holding up?

Sent from my HTC6545LVW using Tapatalk

CJ428 you sold out of these right?

Kinda sorta lol. I have the protype on my car and a brand new fully assembled "Terminator" engraved lower on the shelf. Plus 2 spare Terminator engraved pulleys in boxes that I plan to keep. I only have 1 Terminator but I have 4 pulleys, well actually its 5 if you count the "reject" one that became a clock in my office.

I don't think anyone would want to pay what it would take for me to part with one of the remaining ones. More than likely the last run was it so there won't ever be anymore.

ONE MORE RUN! ONE MORE RUN! ONE MORE RUN!

How much for the one you have?

How much for the one you have?

Nothing against you Nate but theres always lots of talk until its time to pony up the money then all of a sudden there's only a few buyers. I'm not saying you d be that way but if I had 40 people in here begging me to make more id probably still have to work to get 20 sold.

The thought has crossed my mind to build new drive mechanisms for these lowers one that would be stout enough to replace the original tribar setup and not require a locking hub.

If I did this it would probably stimulate 4lb lower pulley demand for big blower guys. The only problem is im guessing the final product would be close to a grand and I don't think that'll sell well.

I might venture by the machine shop this winter and discuss the beefed up drive mechanism.

The thought has crossed my mind to build new drive mechanisms for these lowers one that would be stout enough to replace the original tribar setup and not require a locking hub.

If I did this it would probably stimulate 4lb lower pulley demand for big blower guys. The only problem is im guessing the final product would be close to a grand and I don't think that'll sell well.

I might venture by the machine shop this winter and discuss the beefed up drive mechanism.

Maybe just sell the upgraded drive mechanisms?

Sent from my SM-N920V using Tapatalk

Sent from my SM-N920V using Tapatalk

Completely understandable. I'd prefer to run a 4lb lower, but looks like I'll have to go back to the stock caged lower, unless I'm lucky enough to score one of these somewhere.

Sent from my SM-G930V using Tapatalk

Sent from my SM-G930V using Tapatalk

Maybe just sell the upgraded drive mechanisms?

Sent from my SM-N920V using Tapatalk

Id think that would make a lot of sense to sell an upgraded drive mechanism. It would work for 4lb caged lowers and stockers as well. Some day as these cars age and stock lowers in good shape are hard to find there will be a need for repair parts. With a new drive system, bearing, a stock lower could be rebuilt better than stock.

The R&D is the most expensive part of the upgraded drive.

Sent from my HTC6545LVW using Tapatalk

Sent from my HTC6545LVW using Tapatalk

CJ428 I've read through the many pages of trials & tribulations of the CJ428 4# caged Cobra lower. I think it would be a shame to put this much effort in to stop now. How many people are willing to put up a deposit so you can see if there's enough interest & need to make another batch assuming you are willing. There was one batch of 5 and one of 20 so far, plus a spare or two. What would the next batch size need to be? Would it be easier for you to just offer the 8.6 caged type pulley. I'm ok with leaving the terminator off and chasing the small parts down myself for mine if it would make your job easier

CJ428 I've read through the many pages of trials & tribulations of the CJ428 4# caged Cobra lower. I think it would be a shame to put this much effort in to stop now. How many people are willing to put up a deposit so you can see if there's enough interest & need to make another batch assuming you are willing. There was one batch of 5 and one of 20 so far, plus a spare or two. What would the next batch size need to be? Would it be easier for you to just offer the 8.6 caged type pulley. I'm ok with leaving the terminator off and chasing the small parts down myself for mine if it would make your job easier

Originally I had the shop make 10 but they made 12. The second run I had them make 20 and they made 30. Once they're setup to make them it costs them next to nothing to make them but I still pay the same price thats one of the turn offs.

When I first contacted them they said the first batch of pulleys would be $XXX's a piece but most of that cost was the design costs and that any future run would be much cheaper. On the second run I ordered double the amount and there were no design costs at that point, and the price was only $20 bucks cheaper. This was disappointing in that I was hoping to get the cost down substantially so I could actually make a little something on them and at the same time drop the selling price considerably.

There was a small group of people that bought the pulleys that were like you, just give me the pulley/basic parts and I'll make it happen attitude. If everyone had that attitude it would make things a lot easier, but the worlds just not that way.

On one of the pulleys the purchaser hit me up about how my pulley was junk and that shortly after startup the snap ring broke, the pulley came loose, walked rearward into the lower pulley bracket and was completely destroyed. After looking at pictures of his install and he had taken it upon himself to weld the press in studs in place and his welds were too tall causing contact with the pulley itself. Then as the tribar self tightened into the dampener it pulled the pulley rearward until the snap ring broke. It was 100% installation error and in the end he agreed it was his mistake. Although for a short while after his first initial contact with me I was pretty concerned I was going to have a big fight on my hand. I knew the pulley, was right they're machined to a way way tighter tolerance than anything the factory pulley ever did.

I had another guy that was concerned because when he spun the pulley by hand he thought it was noisy, so I sent a replacement bearing to him.

On another pulley that was installed it wobbled alittle, apparently the locktite kept the bearing from seating perfectly flush in the bottom so it had a little wobble to it. It was an easy fix but all these things make you sweat bullets when you're selling a product thats over $500 a piece and you make peanuts on. You have to replace a couple of pulleys and pretty soon you're very much in the red.

I'm actually relieved to have made it to the point where I feel any sort of warranty I should give has expired and at this point its every man for himself. I hope that makes sense.

Users who are viewing this thread

Total: 3 (members: 0, guests: 3)