I was watching Bitchin Rides. After seeing what they do and realizing how much they charge just for labor, I wanted to figure out where I am right now in the cost of labor for my build so far.

Here is my formula.

I started this build in May. I counted 25 weekends from when I started up to this past weekend. Multiply that times 2 days per weekend equals 50 days (This does not include 3 day weekends or the time I was on vacation). So, my days/hours will actually be low.

I do not burn the midnight oil. I work between 4 and 8 hours a day on my car. So, I averaged it and decided to say 6 hours a day.

Multiply 6 hours a day times 50 days equals 300 hours.

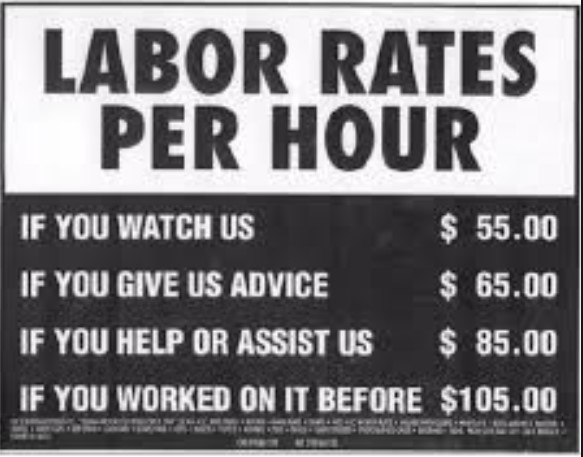

I figure shops charge between $70 to $90 an hour. So, I went with the lower end of a shop that would charge $75 an hour as their labor rate.

Multiply 300 hours times $75 an hour equals $22,500 for labor up to this point in the build and I'm not even half way done.

Damn, I have saved myself $22,500 just in labor by doing it myself. Pretty cool...…

Here is my formula.

I started this build in May. I counted 25 weekends from when I started up to this past weekend. Multiply that times 2 days per weekend equals 50 days (This does not include 3 day weekends or the time I was on vacation). So, my days/hours will actually be low.

I do not burn the midnight oil. I work between 4 and 8 hours a day on my car. So, I averaged it and decided to say 6 hours a day.

Multiply 6 hours a day times 50 days equals 300 hours.

I figure shops charge between $70 to $90 an hour. So, I went with the lower end of a shop that would charge $75 an hour as their labor rate.

Multiply 300 hours times $75 an hour equals $22,500 for labor up to this point in the build and I'm not even half way done.

Damn, I have saved myself $22,500 just in labor by doing it myself. Pretty cool...…