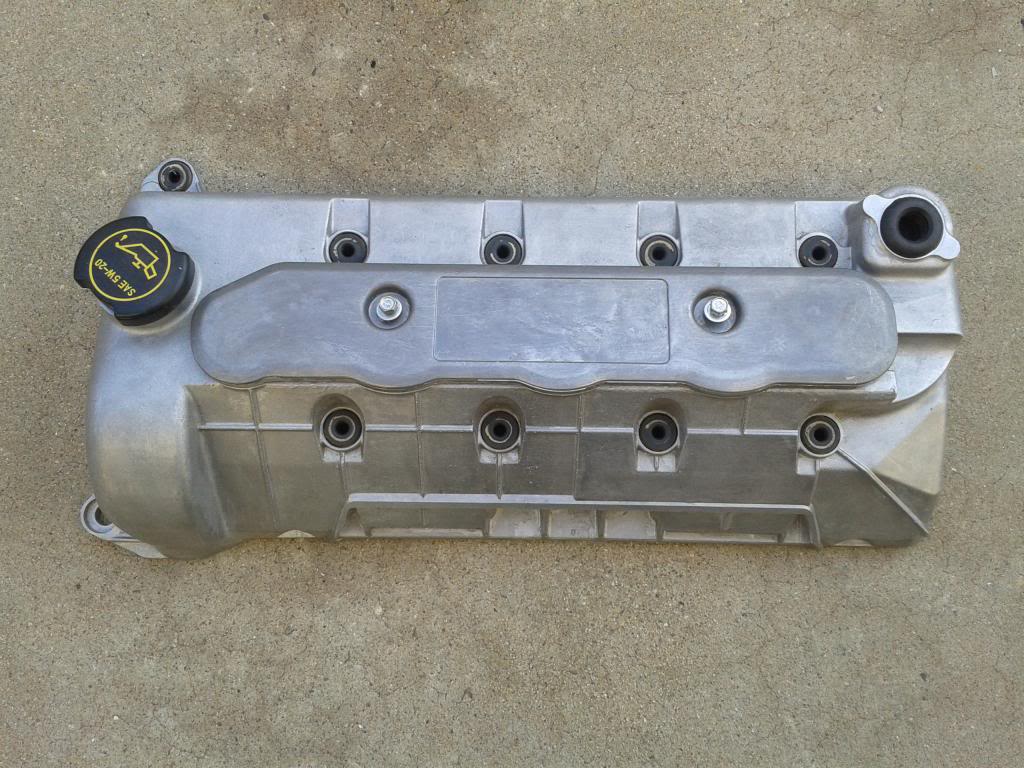

Wasn't sure if most are just using locals or if there is someone (maybe a forum member) that people are recommending/using. I have some local places here in Tampa but I know nothing about them. While motor is out was going to go ahead and do the valve covers, front cover, accessory bracket, etc...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any recommendations on who to use for powdercoating?

- Thread starter Hone03

- Start date

Powder coating is a pretty straight forward process; I don't think it will make much difference who you take it to.

As a design engineer when choosing a finish for hot engine components powder coating is not the first thing that comes to mind. Nothing wrong with it and your engine won't overheat because of it but keep in mind your covering a lot of the engine surface with a fairly thick polymer coating. About 30% if the heat produced by an engine is radiated directly off the surfaces and on this engine that is mainly aluminum which moves heat like a freight train. Powder coating will impeded that process to a fair degree. In a high output FI engine heat is something you want to get rid of at all cost.

I stripped the factory powder coating off my valve covers and am leaving the all exposed aluminum bare. The funny thing is after I stripped the powder coat off I could hardly tell the difference.

Oxides that form turn the surface that nice dull gray and prevents further corrosion while providing maximum heat transfer. If it stains a couple of swipes with scotch brite cleans it up and in no time at all it blends in to the surrounding metal like it never happened. Besides, I like the Factory Worx look engine appearance that is "all business" :rockon:

Powder coating does look great and is tough as nails. A textured finish will provide the better surface than a gloss one but it traps dirt and is harder to clean. Black will dissipate heat better than a lighter color and hides any dirt that gets imbedded in there.

Just something to consider :burnout:

As a design engineer when choosing a finish for hot engine components powder coating is not the first thing that comes to mind. Nothing wrong with it and your engine won't overheat because of it but keep in mind your covering a lot of the engine surface with a fairly thick polymer coating. About 30% if the heat produced by an engine is radiated directly off the surfaces and on this engine that is mainly aluminum which moves heat like a freight train. Powder coating will impeded that process to a fair degree. In a high output FI engine heat is something you want to get rid of at all cost.

I stripped the factory powder coating off my valve covers and am leaving the all exposed aluminum bare. The funny thing is after I stripped the powder coat off I could hardly tell the difference.

Oxides that form turn the surface that nice dull gray and prevents further corrosion while providing maximum heat transfer. If it stains a couple of swipes with scotch brite cleans it up and in no time at all it blends in to the surrounding metal like it never happened. Besides, I like the Factory Worx look engine appearance that is "all business" :rockon:

Powder coating does look great and is tough as nails. A textured finish will provide the better surface than a gloss one but it traps dirt and is harder to clean. Black will dissipate heat better than a lighter color and hides any dirt that gets imbedded in there.

Just something to consider :burnout:

I'm sending off a bunch of stuff next week to Brian, aka blkGT500inca, next week to be powder coated. Granted he's in CA and that's quite a ways away from you but if you search for his name and view his finished pieces they are top notch!

I'm sending off a bunch of stuff next week to Brian, aka blkGT500inca, next week to be powder coated. Granted he's in CA and that's quite a ways away from you but if you search for his name and view his finished pieces they are top notch!

:beer:

Powder coating is a pretty straight forward process; I don't think it will make much difference who you take it to.

Yes and no. There's a little more to it than that. It's all in the prep! A guy that powder coats things in his home oven while his wife is at the grocery store is not going to get the same durable product that a full time production facility will.

Chemically stripping off the old finish with a paint remover like you did is the first step. Careful stripping magnesium! This is where a novice may call it good and move on to the coating. But on something cast aluminum like these valve covers, they suck up quite a bit of oils.

The next step is to outgas the covers by baking them in the oven at a higher temp that what the powder coating needs to cure. Usually around 450-500. This will bring all of the deep imbedded oils to the surface to be re-cleaned.

Up next is media blasting. You'd be surprised by how many reputable shops skip this step. To completely clean the part and to get the surface ready for it's coating, it is highly recommended that the part be media blasted with the proper media, at the correct pressure. Not every part is the same.

On steel parts, I like to go a step further and chemically etch the metal with iron phosphate. The phosphate also makes the steel so it won't rust.

Shooting the powder isn't the same for everyone either. The type of gun your coater uses can greatly effect the outcome of certain candy and textured powders. A $200 gun from harbor freight or Eastwood is NOT going to give you the same results as say, a $5k system from one of the leading manufacturers.

As a design engineer when choosing a finish for hot engine components powder coating is not the first thing that comes to mind. Nothing wrong with it and your engine won't overheat because of it but keep in mind your covering a lot of the engine surface with a fairly thick polymer coating. About 30% if the heat produced by an engine is radiated directly off the surfaces and on this engine that is mainly aluminum which moves heat like a freight train. Powder coating will impeded that process to a fair degree. In a high output FI engine heat is something you want to get rid of at all cost.

While the powder will insulate some of the heat...on a daily driven street car or even a mild track toy, I wouldn't worry about it. You are certainly right about better coatings though.

I do a lot of high temp ceramic coatings on a lot of exhaust components that would certainly be a better choice. There's about a dozen different ceramic colors, compared to the 1,000's of different powder colors though, highly limiting your choices.

I stripped the factory powder coating off my valve covers and am leaving the all exposed aluminum bare. The funny thing is after I stripped the powder coat off I could hardly tell the difference.

Oxides that form turn the surface that nice dull gray and prevents further corrosion while providing maximum heat transfer. If it stains a couple of swipes with scotch brite cleans it up and in no time at all it blends in to the surrounding metal like it never happened. Besides, I like the Factory Worx look engine appearance that is "all business" :rockon:

Agreed. :beer:

Powder coating does look great and is tough as nails. A textured finish will provide the better surface than a gloss one but it traps dirt and is harder to clean. Black will dissipate heat better than a lighter color and hides any dirt that gets imbedded in there.

This guy knows. lol

Just something to consider :burnout:

Your milage may vary.

-Brian

The Powder House

Last edited:

See what I mean. Some coaters have a hard time getting down in the coil pack holes. Is it a big deal? Maybe not, but to some, IT MATTERS.

I assure you, not every powder coater can do this.... These are all powder with hydro graphics!

Or this 100% powder coated logo.

-Brian

The Powder House

I assure you, not every powder coater can do this.... These are all powder with hydro graphics!

Or this 100% powder coated logo.

-Brian

The Powder House

Last edited:

Ok now that's some nice work!

Yea that was one of our first sets we did. It was a pain in the dick first starting out, once we bought a nice oven, spray booth, and a nicer gun it came together for us. It takes time to get good despite how easy some make it look.

So you guys are deleting all my post now? That seems logical....I suppose that no one is allowed to give any kind of input? Changed my sig too. I'm not selling anything, not giving prices or anything, I was actually trying to give some input on getting some covers done. But you moderators do whatever you want. Feel free to send me a PM and let me know what I am doing wrong.

Stuff looks great Brian. Hope that we are able to do some business. Awaiting your cover samples.

Stuff looks amazing man. I need to work out a deal with you

Stuff looks amazing man. I need to work out a deal with you

..........and how!

I am curious how they produce those patterns. Innovation is a wonderful thing. What's next?

Are you asking how they do the hydro film?

Wow, that is some really impressive work.

Wow, that is some really impressive work.

Agreed :thumbsup:

WoW!!! PM sent

I'm sending off a bunch of stuff next week to Brian, aka blkGT500inca, next week to be powder coated. Granted he's in CA and that's quite a ways away from you but if you search for his name and view his finished pieces they are top notch!

First name that came to my mind. Never dealt with him, but have seen his posts with his and Zak's work.

Thanks Fellas!

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)