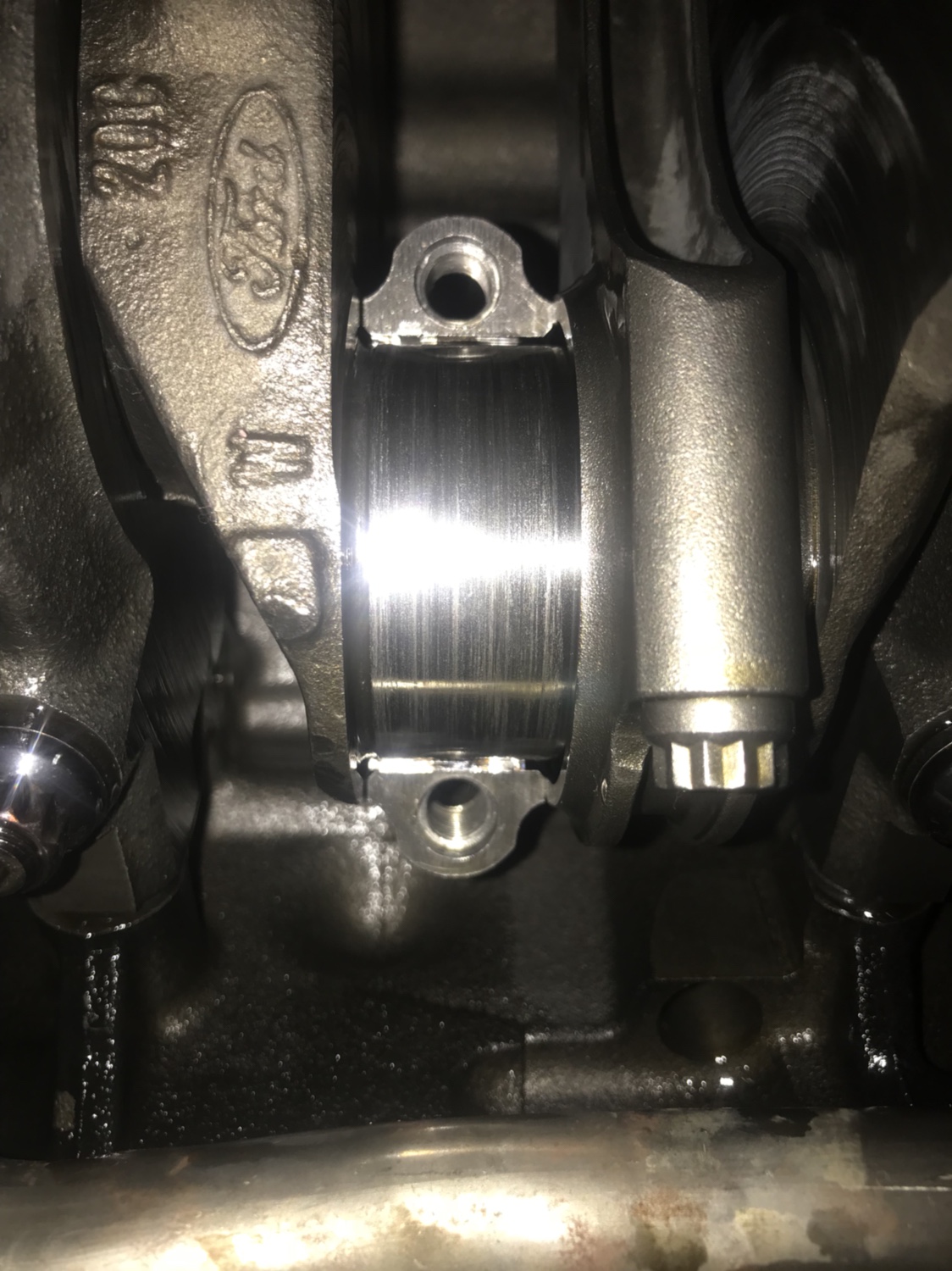

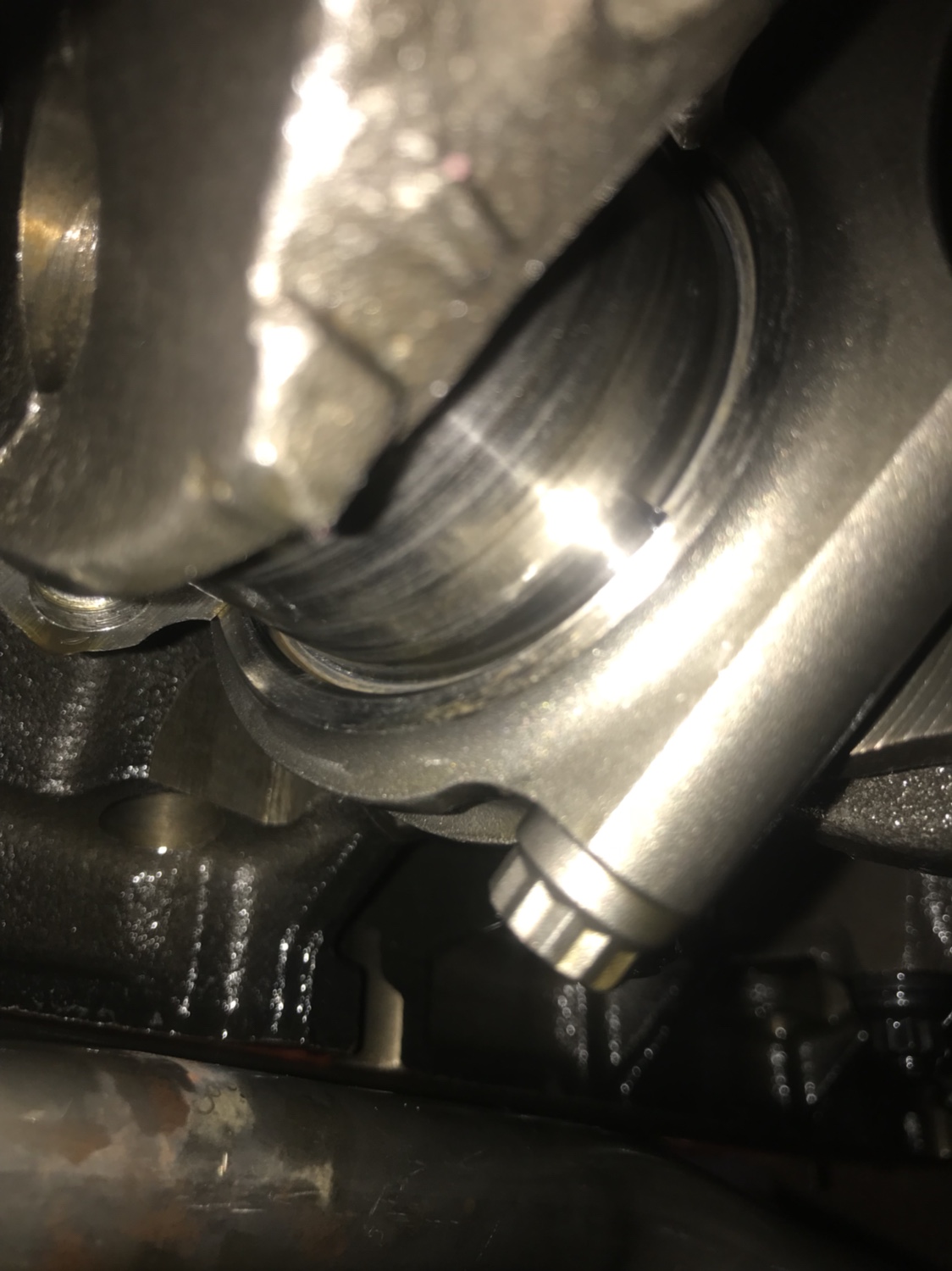

Hey all. Had my shortblock forged a year ago and been driving it for that long too. Well last weekend I heard a knocking sound. Heard it was coming from the motor and dropped the next day. I never lost oil pressure, motor was primed before first start, new oil pump was installed, always full on oil and changed regularly. Well this is what I found. Cylinders 1 and 5’s connecting rods are installed backwards and the bearings are riding on the crank fillets. The bearing on cylinder 1’s connecting rod wasn’t installed properly either. Monday can’t get here quick enough.

Sent from my iPhone using Tapatalk Pro

Sent from my iPhone using Tapatalk Pro