We have a 2012 Mustang 5.0 Automatic bolt ons with JLT Plastic Air intake, LT headers with x-pipe and cat-back, and 2018 Intake manifold.

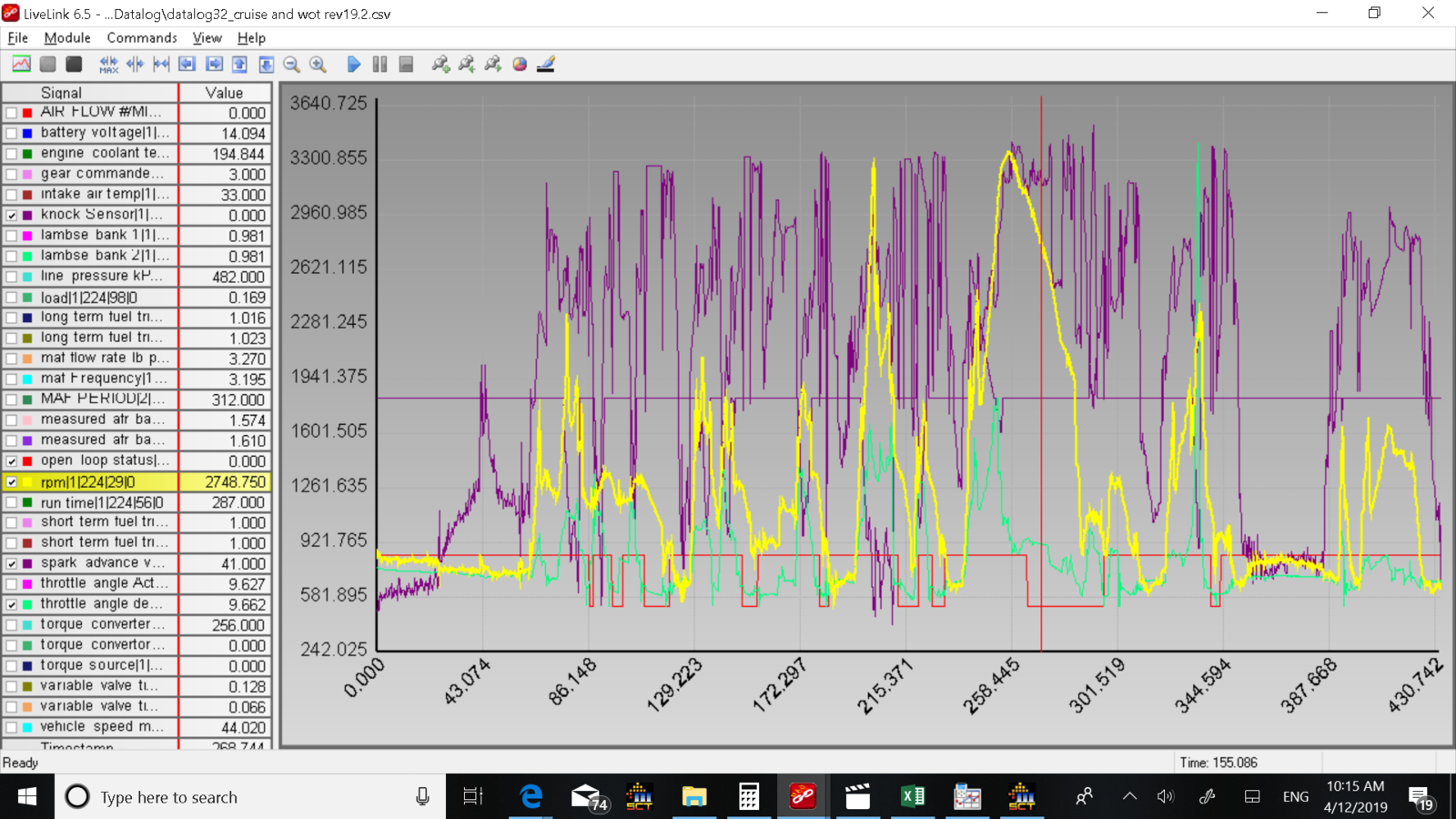

We're in the process of tuning it, the car at cruise when we hold it in 3rd gear at 3000-4000 RPM will shift from OP loop to CL loop and once it goes to CL the Check Engine light will flash rapidly and cause the car have random misfire to cut fuel and after couple of seconds will go OP loop and check engine will go and everything goes fine.

I would like to know why it's doing this and how to tackle this issue and fix it? The code we received P0300. we checked spark plugs and coils and everything is ok. We changed the Purge valve and still the issue there. Do you think is tuning issue or mechanical issue? Please help

here you go the datalog for reference.

We're in the process of tuning it, the car at cruise when we hold it in 3rd gear at 3000-4000 RPM will shift from OP loop to CL loop and once it goes to CL the Check Engine light will flash rapidly and cause the car have random misfire to cut fuel and after couple of seconds will go OP loop and check engine will go and everything goes fine.

I would like to know why it's doing this and how to tackle this issue and fix it? The code we received P0300. we checked spark plugs and coils and everything is ok. We changed the Purge valve and still the issue there. Do you think is tuning issue or mechanical issue? Please help

here you go the datalog for reference.