For those of you who would like to have your existing intercooler (stock or KB Bigun) mod by J2Fab. Make sure you read this first ESPECIALLY for those who is running KB 3.6 / 4.2.

Last year I have my KB Bigun (the early version) IC removed and sent back to KB to have it revised to the newer revision mounting flanges updated. I also decided to have the 1" (inlet and outlet) intercooler mod from J2Fab. The J2Fab IC mod bored out the intercooler inlet and outlet and includes a CNC billet aluminum water manifold machined to accept (2) -16AN caps.

As a result, the J2Fab IC mod will provides more than 2X the cross sectional area than the stock (212% to be exact).

This IC mod from J2Fab ONLY provides HALF of the solution which is on the intercooler side. The other half of the solution which is the plumbing portion really depends on the end user to figure out. And since I have the KB 3.6 LC supercharger with a 3.75" upper pulley and stock lower pulley. Thing does NOT look good. It REQUIES a special solution ESPECISLLY on the upper intercooler outlet in order to provides enough clear for the supercharger belt.

Since the biggest concern is the upper outlet so I decided to tackle that first. I started by using an Earl's -16AN fitting (P/N AT704616ERL) with a 45 degree barb outlet and a 45 degree 16 gage aluminum tubing. I cut off the barb outlet portion and welded in a 45 degree aluminum tubing but the result is NOT something I really like.

So back to the drawing board. I started by utilizing (2) Earl's -16AN caps and taking LOTS of measurements and transfer all those measurements into CAD - I used to be a Catia CAD modeler / designer for more than a decade. Things started to look good as CAD models getting more mature. I sent out the shorter (more cost effective) CAD version to a 3D printing shop and have it printed in aluminum. This shorter (more cost effective) 3D printed aluminum elbow would welds to a 3" long 16 gage aluminum tubing as shown in the below picture.

I then started working on the (2) -16 AN caps. I first drilled out the blocked caps with a final hole size of 7/8". Then 1 of the cap needs to mill down by 3.3mm (my originally calculation only requires 2.5mm) and this milled down cap is used on the upper IC outlet. With all the necessary parts in place including the KB 3.6 installed. The end result is I have 8.5mm of clearance between the outlet fitting and the supercharger belt - remember I am using the 3.75" upper pulley. If I switch to 3.625" upper pulley, the clearance increase to ~ 9.25mm. A 3.5" upper pulley will results in ~10mm clearance.

Things starts to fall into places so I switch attention to the lower IC inlet. I started out a shorter (more cost effective) CAD version and have it 3D printed in aluminum. This shorter (more cost effective) 3D printed aluminum elbow would welds to a ~ 5" long 45 degree 16 gage aluminum tubing and a 1/4" NPT weld bung as shown in the below picture.

These 2 short (more cost effective) printed pieces work out great but I just don't like all these welds. So I re-visit the CAD models and have everything 3D printed in 1 single piece. While revising on the CAD models, I discovered the upper outlet elbow can be moved backward by another 1mm. As a result, I end up having 9.5mm of clearance between the outlet fitting and the supercharger belt - remember I am using the 3.75" upper pulley. If I switch to 3.625" upper pulley, the clearance increase to ~ 10.25mm. A 3.5" upper pulley will results in ~11mm clearance. The below picture shows the 1 piece 3D printed inlet and outlet welded to the -16 AN caps.

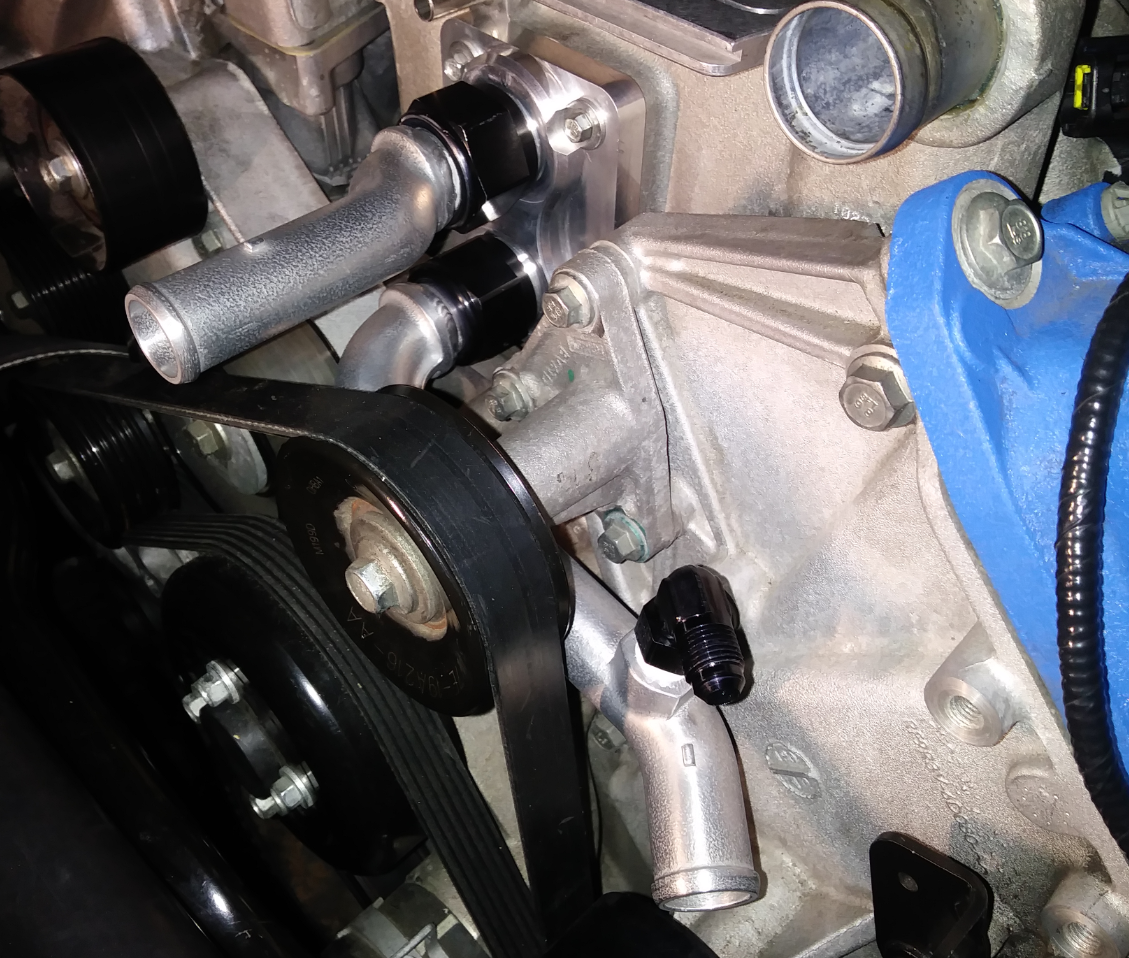

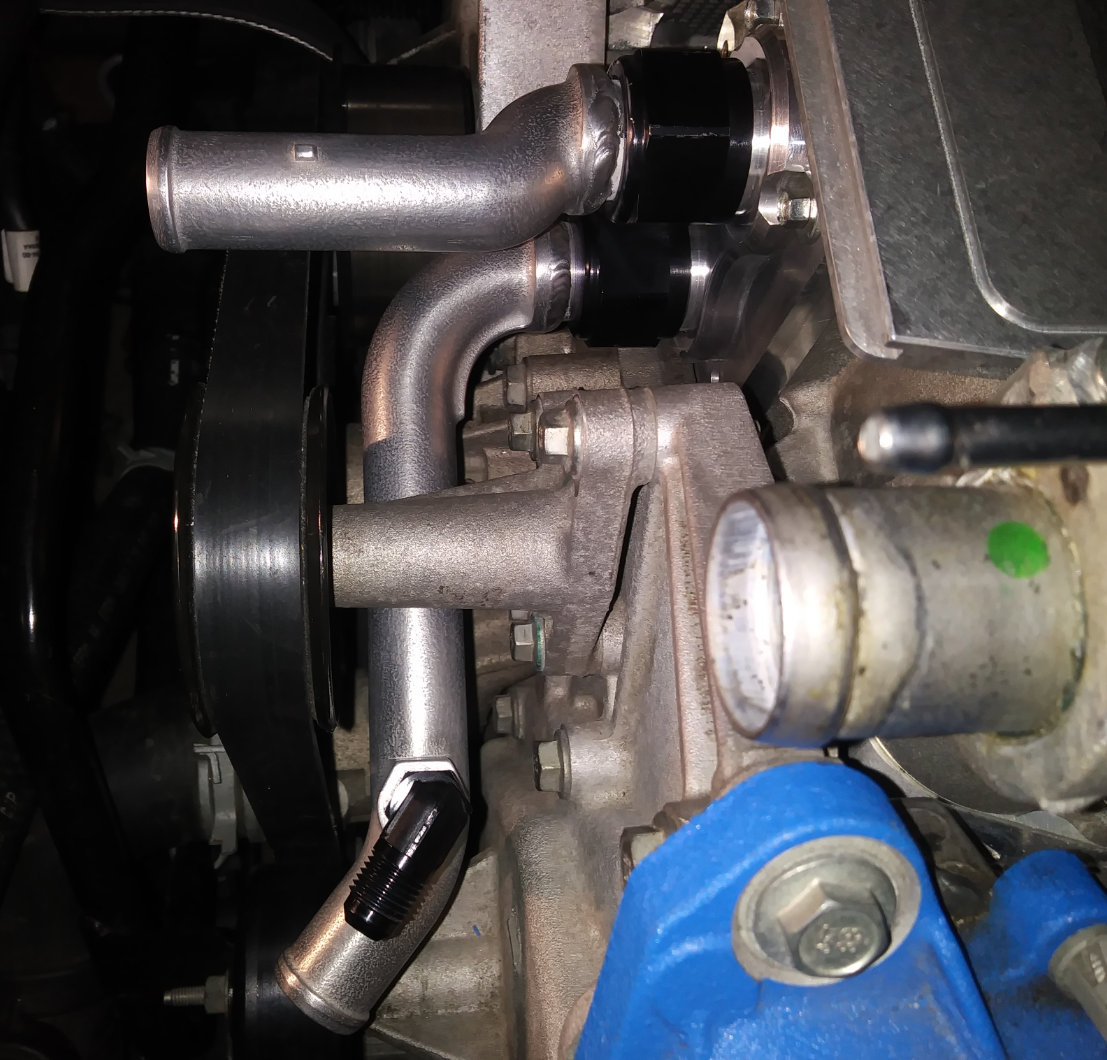

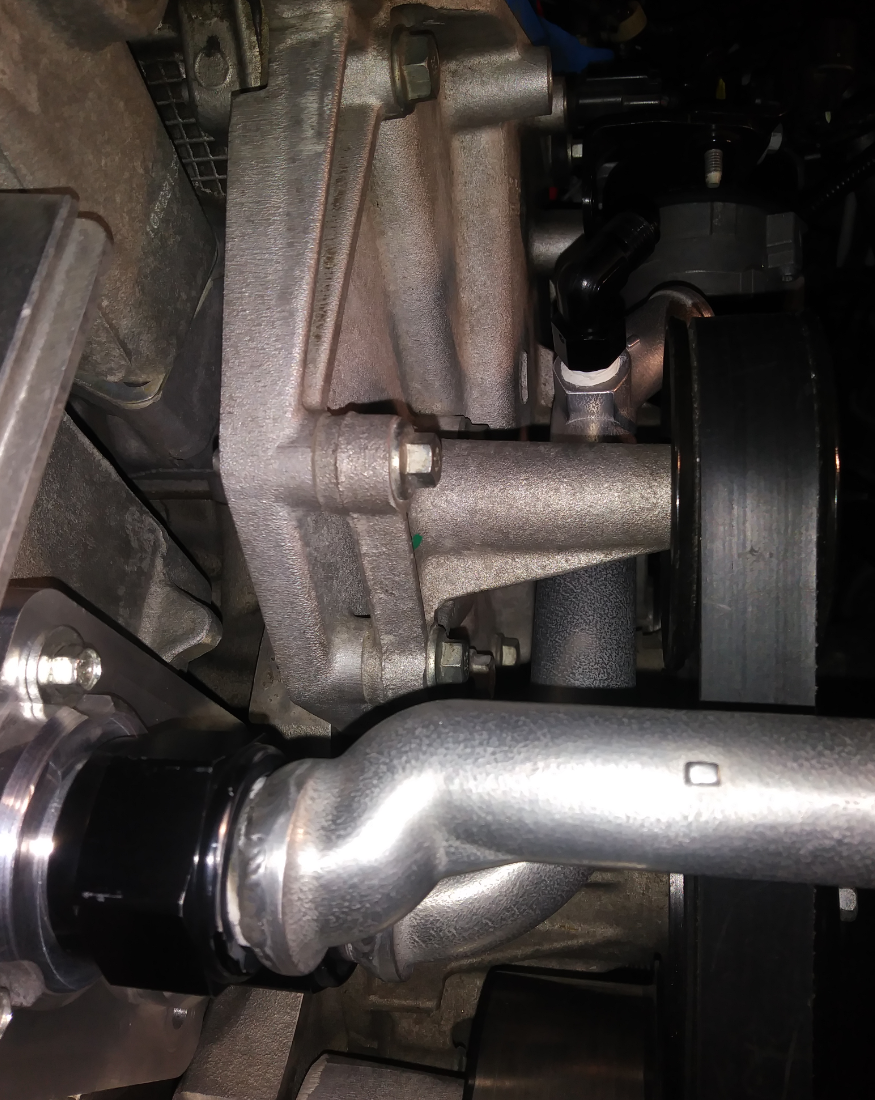

Pictures below show everything installed on the engine.

So at the end, it cost me 1K to 3D printed everything (total 4 pieces - 1" lower IC inlet with integrated 1/4" NPT bung, 1" IC upper outlet, 1" T with a 3/4" spout and integrated 1/4" NPT bung and flow restrictor to the IC reservoir, and finally a special 1" T with 1" outlet and 3/4" outlet) and I am doing ALL the CAD modeling myself. The shorter (more cost effective) pieces would still cost ~ $450 to have a complete set (4 pieces). For those who has the KB 3.6 / 4.2 supercharger and wants to do the J2Fab 1" intercooler mod. Better think twice before pulling the trigger. I guarantee you will run into the same problem as encountered. Have fun.

Last year I have my KB Bigun (the early version) IC removed and sent back to KB to have it revised to the newer revision mounting flanges updated. I also decided to have the 1" (inlet and outlet) intercooler mod from J2Fab. The J2Fab IC mod bored out the intercooler inlet and outlet and includes a CNC billet aluminum water manifold machined to accept (2) -16AN caps.

As a result, the J2Fab IC mod will provides more than 2X the cross sectional area than the stock (212% to be exact).

This IC mod from J2Fab ONLY provides HALF of the solution which is on the intercooler side. The other half of the solution which is the plumbing portion really depends on the end user to figure out. And since I have the KB 3.6 LC supercharger with a 3.75" upper pulley and stock lower pulley. Thing does NOT look good. It REQUIES a special solution ESPECISLLY on the upper intercooler outlet in order to provides enough clear for the supercharger belt.

Since the biggest concern is the upper outlet so I decided to tackle that first. I started by using an Earl's -16AN fitting (P/N AT704616ERL) with a 45 degree barb outlet and a 45 degree 16 gage aluminum tubing. I cut off the barb outlet portion and welded in a 45 degree aluminum tubing but the result is NOT something I really like.

So back to the drawing board. I started by utilizing (2) Earl's -16AN caps and taking LOTS of measurements and transfer all those measurements into CAD - I used to be a Catia CAD modeler / designer for more than a decade. Things started to look good as CAD models getting more mature. I sent out the shorter (more cost effective) CAD version to a 3D printing shop and have it printed in aluminum. This shorter (more cost effective) 3D printed aluminum elbow would welds to a 3" long 16 gage aluminum tubing as shown in the below picture.

I then started working on the (2) -16 AN caps. I first drilled out the blocked caps with a final hole size of 7/8". Then 1 of the cap needs to mill down by 3.3mm (my originally calculation only requires 2.5mm) and this milled down cap is used on the upper IC outlet. With all the necessary parts in place including the KB 3.6 installed. The end result is I have 8.5mm of clearance between the outlet fitting and the supercharger belt - remember I am using the 3.75" upper pulley. If I switch to 3.625" upper pulley, the clearance increase to ~ 9.25mm. A 3.5" upper pulley will results in ~10mm clearance.

Things starts to fall into places so I switch attention to the lower IC inlet. I started out a shorter (more cost effective) CAD version and have it 3D printed in aluminum. This shorter (more cost effective) 3D printed aluminum elbow would welds to a ~ 5" long 45 degree 16 gage aluminum tubing and a 1/4" NPT weld bung as shown in the below picture.

These 2 short (more cost effective) printed pieces work out great but I just don't like all these welds. So I re-visit the CAD models and have everything 3D printed in 1 single piece. While revising on the CAD models, I discovered the upper outlet elbow can be moved backward by another 1mm. As a result, I end up having 9.5mm of clearance between the outlet fitting and the supercharger belt - remember I am using the 3.75" upper pulley. If I switch to 3.625" upper pulley, the clearance increase to ~ 10.25mm. A 3.5" upper pulley will results in ~11mm clearance. The below picture shows the 1 piece 3D printed inlet and outlet welded to the -16 AN caps.

Pictures below show everything installed on the engine.

So at the end, it cost me 1K to 3D printed everything (total 4 pieces - 1" lower IC inlet with integrated 1/4" NPT bung, 1" IC upper outlet, 1" T with a 3/4" spout and integrated 1/4" NPT bung and flow restrictor to the IC reservoir, and finally a special 1" T with 1" outlet and 3/4" outlet) and I am doing ALL the CAD modeling myself. The shorter (more cost effective) pieces would still cost ~ $450 to have a complete set (4 pieces). For those who has the KB 3.6 / 4.2 supercharger and wants to do the J2Fab 1" intercooler mod. Better think twice before pulling the trigger. I guarantee you will run into the same problem as encountered. Have fun.