I tried another experiment with Weld wheels (there have been a handful up to now) and got them on the car today.

This time it was an attempt at improving the fit with the standard Weld RTS, 15x10 wheel for S197's. I chose S71's with a black star. P/n: 71MB-510A75A.

The typical S197 with 15x10 Weld wheels and Mickey Thompson Radial Pros or Mickey Thompson Pro Bracket Radials doesn't look all that great. The tire bulges over the wheel and the tires stick out past the wheel lip.

I wanted the tire tucked in or flush with the wheel lip at a minimum. I also wanted less of a sidewall bulge from a wheel not wide enough for the tire. This called for a compromise on the tire.

I typically run an MT Pro Bracket Radial (3355R). These are .8" more wide than an MT Radial Pro (3754X) and more forgiving on less than ideal surfaces (for me, they work better on the street and definitely get me down the track more often than anything else I've ever tried). For this project, I switched the narrower Radial Pro.

I also noticed that with the same wheel and spec, one with a beadlock and one without, the beadlock wheel will stick out noticeably farther. For this reason, I started with a non beadlock wheel this time.

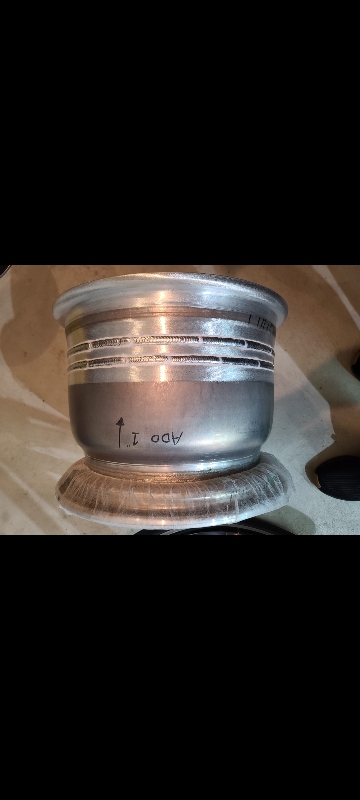

The last thing I did was have the wheels windened by Weldcraft Wheels. I had them add 1" to add to the backspace, making them 15x11, thinking this may give the Radial Pro a more vertical sidewall for a better appearance and hopefully help it tuck in under the fender lip.

I called MT to verify how wide of a wheel I could have that tire mounted on, without a beadlock. 11" was the answer.

Once I got the wheels back from Weldcraft, I took them to a local powdercoater. He coated the front lip and barrel, gloss black to match the black star on the face, while leaving the sides and chamfered edges of the star with the machined look. He also mounted and balanced them, as well as applied Permatex HI Tack to the sidewalls to keep the wheel from spinning inside the tire.

I called Weld and got some of the hologram, Weld decals to add to the wheels after the powdercoat.

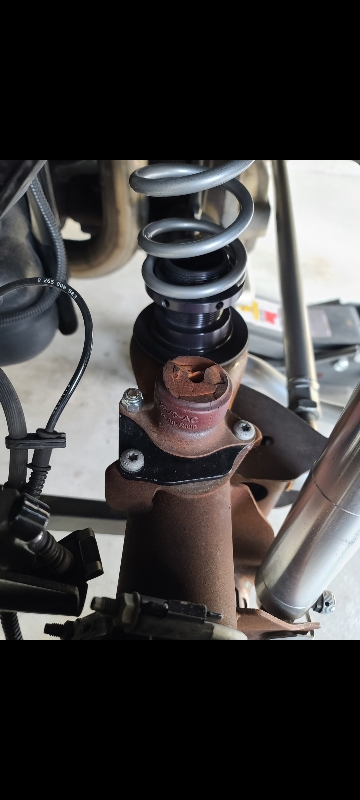

Upon a test fit, I found contact in the following places with the axle completely unloaded (hanging), the bump stop bracket and shock. The emergency brake lines touch the wheel as well. My friend, Bob VanRooy cut the bump stop brackets out and supplied some relocation plates for the bump stops (see pic). I bought some 175lb rated zip ties and used three per side (overkill, I know) to pull the emergency brake line away from the wheel.

I'm pleased with the outcome. They look nice, fit nice and are a little different from the typical Weld wheel you see around

Sent from my SM-G988U using Tapatalk

This time it was an attempt at improving the fit with the standard Weld RTS, 15x10 wheel for S197's. I chose S71's with a black star. P/n: 71MB-510A75A.

The typical S197 with 15x10 Weld wheels and Mickey Thompson Radial Pros or Mickey Thompson Pro Bracket Radials doesn't look all that great. The tire bulges over the wheel and the tires stick out past the wheel lip.

I wanted the tire tucked in or flush with the wheel lip at a minimum. I also wanted less of a sidewall bulge from a wheel not wide enough for the tire. This called for a compromise on the tire.

I typically run an MT Pro Bracket Radial (3355R). These are .8" more wide than an MT Radial Pro (3754X) and more forgiving on less than ideal surfaces (for me, they work better on the street and definitely get me down the track more often than anything else I've ever tried). For this project, I switched the narrower Radial Pro.

I also noticed that with the same wheel and spec, one with a beadlock and one without, the beadlock wheel will stick out noticeably farther. For this reason, I started with a non beadlock wheel this time.

The last thing I did was have the wheels windened by Weldcraft Wheels. I had them add 1" to add to the backspace, making them 15x11, thinking this may give the Radial Pro a more vertical sidewall for a better appearance and hopefully help it tuck in under the fender lip.

I called MT to verify how wide of a wheel I could have that tire mounted on, without a beadlock. 11" was the answer.

Once I got the wheels back from Weldcraft, I took them to a local powdercoater. He coated the front lip and barrel, gloss black to match the black star on the face, while leaving the sides and chamfered edges of the star with the machined look. He also mounted and balanced them, as well as applied Permatex HI Tack to the sidewalls to keep the wheel from spinning inside the tire.

I called Weld and got some of the hologram, Weld decals to add to the wheels after the powdercoat.

Upon a test fit, I found contact in the following places with the axle completely unloaded (hanging), the bump stop bracket and shock. The emergency brake lines touch the wheel as well. My friend, Bob VanRooy cut the bump stop brackets out and supplied some relocation plates for the bump stops (see pic). I bought some 175lb rated zip ties and used three per side (overkill, I know) to pull the emergency brake line away from the wheel.

I'm pleased with the outcome. They look nice, fit nice and are a little different from the typical Weld wheel you see around

Sent from my SM-G988U using Tapatalk

Last edited: