Need help! Installing thse on my 2003 GT. I am stuck on the passenger side. How the hell do you tighten the nut that is above the second exhaust port (counting from the front)? There is absolutely no clearance to get at it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BBK 1615 Shorty Header Install Help

- Thread starter SilverGT1

- Start date

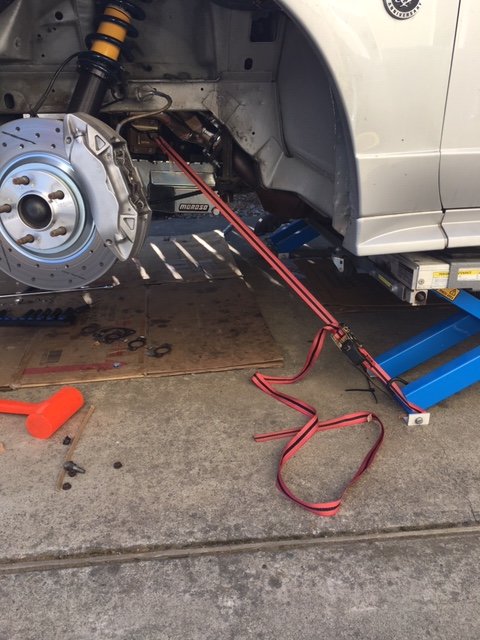

Pictures?

My question is the k member dropped? I used a wrench i cut and shortened to tighten them when I had the I also used 1/4 ratchets and etc to make it work but only when the k member was droppedPictures?

Sent from my SM-N975U using Tapatalk

Like thisMy question is the k member dropped? I used a wrench i cut and shortened to tighten them when I had the I also used 1/4 ratchets and etc to make it work but only when the k member was dropped

Sent from my SM-N975U using Tapatalk

Sent from my SM-N975U using Tapatalk

My question is the k member dropped? I used a wrench i cut and shortened to tighten them when I had the I also used 1/4 ratchets and etc to make it work but only when the k member was dropped

Sent from my SM-N975U using Tapatalk

Last I checked based on other threads he has posted in the K is out because he is in the middle of a swap.

Ok i wasn't sure was it still out or back in ? LolLast I checked based on other threads he has posted in the K is out because he is in the middle of a swap.

Sent from my SM-N975U using Tapatalk

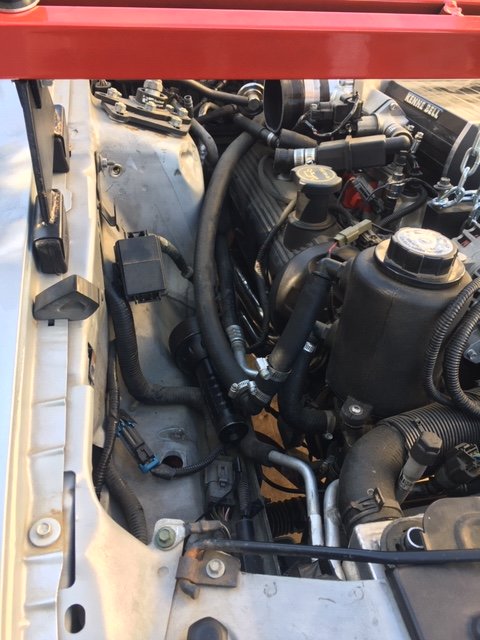

Yes. Everything out. K-member, starter, motor mount. I am actually working on this this right now. What I ended up doing was pulling the motor to the driver side with a ratcheting strap . Then removed my JLT CAI. Pain in the butt because of my MM strut brace which had to come out. Moved my SC coolant lines out of the way. Then I was able to get at it. Then I McGyvered a tool so that I could get some torque on the nut. I took a 13mm and found a nut/bolt combo that would take a 15mm. Placed that through the box end. This allowed me to get in there and get it very tight. I am very worried about the gaskets that BBK provided. I wish I would have bought some of the metal stock ones. Also, since there is not direct access to most of the nut / bolts, there is no way to evenly torque these. I am torqueing until super tight. Probably killing the fiber gasket. These were a waste of money. I thought install would be muck easier. Driver side was not much better.

@SilverGT1

I know the pictures don't tell the full story but was there no way to get in there with a dog bone (torque adapter) or crows foot?

Would it have been possible to put a socket on the nut and then connect and extension? I have to change one of the plugs on my truck this way. Basically drop the socket in the hole and then put the extension in place followed by the ratchet.

I know the pictures don't tell the full story but was there no way to get in there with a dog bone (torque adapter) or crows foot?

Would it have been possible to put a socket on the nut and then connect and extension? I have to change one of the plugs on my truck this way. Basically drop the socket in the hole and then put the extension in place followed by the ratchet.

Last edited:

There is no way you can get at it with a dogbone. Probably not a crows foot either once you get your extension or ratchet in it. There is maybe only 1" or just a little more from the flange to the the exhaust tube that is directly in front of the Stud (or bolt). There is no way you are going to get any ratchet on there. You might be able to get a ratcheting box end wrench on it if you use a bolt instead of the stud. If I were to do it again, I would have used a bolt here instead of the stud. I would probably not have used the 10mm head bolt that BBK supplied but used a 13mm head bolt. Why? 1) 10mm wrenches are too short, not enough torque in this weird application. 2) You can buy (and I have) extra long ratcheting boxend wrenches that might get you enough torque. 3) Using the stud prevents any possibility of slipping a boxend over it. there is no clearance between it and the exhaust tube.

Additional notes:

I found the best way to get this to mount was to install the 2nd and 3rd stud / bolts first to hold the gasket in place (counting from front to rear). The header is slotted for these two. Then you can slide the header into place. tighten down #3 to hold in place while you install the rest of your hardware.

On the bottom, I ended up cutting down the bolts for holes 2, 3 and 4. I cut these down by approximately 6mm.

Additional notes:

I found the best way to get this to mount was to install the 2nd and 3rd stud / bolts first to hold the gasket in place (counting from front to rear). The header is slotted for these two. Then you can slide the header into place. tighten down #3 to hold in place while you install the rest of your hardware.

On the bottom, I ended up cutting down the bolts for holes 2, 3 and 4. I cut these down by approximately 6mm.

@SilverGT1

So you're telling me one of these wouldn't fit in there?

This is what I was talking about when I mentioned a dog bone/torque adapter. From your description I think this would fit. Even if they were to chick to slip between the stud and header tube they can easily be shaved down. Even at 50% thickness they will still handle the required torque spec. I know because I've done it more than once.

Sent from my SM-G970U using the svtperformance.com mobile app

So you're telling me one of these wouldn't fit in there?

This is what I was talking about when I mentioned a dog bone/torque adapter. From your description I think this would fit. Even if they were to chick to slip between the stud and header tube they can easily be shaved down. Even at 50% thickness they will still handle the required torque spec. I know because I've done it more than once.

Sent from my SM-G970U using the svtperformance.com mobile app

Yes. Those would stand a chance as long as the shaft is long enough that the breaker bar / ratchet clears the exhaust tube. Even a better chance if you use a bolt instead of the stud.

Essentially, the same idea as what I cobbled together.

Essentially, the same idea as what I cobbled together.

Yes. Those would stand a chance as long as the shaft is long enough that the breaker bar / ratchet clears the exhaust tube. Even a better chance if you use a bolt instead of the stud.

Essentially, the same idea as what I cobbled together.

I figured there was some miscommunication when I mentioned dog bone. I assumed you were thinking of those combination wrench things.

You can also use an extension to space the ratchet or torque wrench away from the tubes to gain more clearance as the extension is obviously smaller than the head of the ratchet. If you ever use these they need to be turned to the 90 or 270 degree location to maintain the same torque value if using a torque wrench. If you have to go to any other angle you can do a little math to maintain the same torque value based on that angle.

I feel your pain, sounds like you are already using studs. We had to start with the difficult ones first and had the header loose to the end of the stud to get the nut on and then a stubby open end to get it tightened that I sanded down for clearance

Sent from my iPhone using the svtperformance.com mobile app

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)