Not really sure where else I could have posted but just looking for advice.

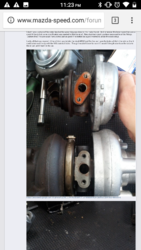

I got a 96 Ranger Splash with a 2.3T motor from an old TBird turbocoupe. I have a problem getting anything to seal the drain flange to the turbo housing.

The oil supply has a boss that is threaded and works with no leaks under pressure. It has me wondering if the drain hole could be tapped and threaded for a barb fitting?

This isn't something I intend to attempt, I'm beyond frustrated. I would seek out someone to do that task for me.

I got a 96 Ranger Splash with a 2.3T motor from an old TBird turbocoupe. I have a problem getting anything to seal the drain flange to the turbo housing.

The oil supply has a boss that is threaded and works with no leaks under pressure. It has me wondering if the drain hole could be tapped and threaded for a barb fitting?

This isn't something I intend to attempt, I'm beyond frustrated. I would seek out someone to do that task for me.