Today was lift install day... finally! I had been putting this off for a long time. I had to solve the delivery and weight issue (almost a couple thousand pounds). This thing is close to a couple thousand pounds shipped! If you accept delivery, YOU have to remove it from the delivery vehicle. I spoke with a Bendpak rep who gave me a local installer's info. For a fee, the installer took delivery of the lift and then came out and made it all happen. The fee was WELL worth it. This lift is MASSIVE and is seriously heavy. Plus, all of the drilling and cable/hose installation was best left to the professionals in my case.

I chose to go with a 2-post lift initially (I have another outlet wired for a possible 4-post lift addition). I went with this lift:

Super-Tall Two-Post Lift - High Rise Lift - XPR-10ASLX

It was their tallest 2-post lift. I'm not sure I'll need the extra height, but since I had the space, I went big. I also wanted the option to be able to lift stuff high enough to transfer to my loft (possibly from the back of my truck)

Now for pictures of the process...

First off, the 3 Cobras got relocated to the house garage:

Once the installers arrived, we discussed options and decided the best option for me was to have the lift installed "backwards." This would allow me to back the vehicles into position vs. driving into the lift forward. The reasons I went with this option were:

1. I normally back all of my vehicles into the garage.

2. The lift motor is on the passenger side tower. Installing it "backwards" more closely aligned it with my 220 prewired power source.

3. By backing the vehicles into position, the mirrors never pass between the towers. This allowed me to use the narrow setting of the lift and still be able to lift my F-150.

4. By installing the lift backwards, it deconflicted with the door on the nearby wall.

Back to the process...

I pulled my truck into position and we mapped out an exact position of the lift:

Since I have foam sprayed walls, the installer measured off the front garage door to find "square."

Next was tackling the monster on the trailer. They expertly used an engine hoist:

They pushed/pulled the lift into the garage while the heavy tower balanced. Fortunately the nylon wheels didn't mar my floor:

They put down cardboard to protect the floor... winning the battle:

In with the second column/tower:

At this point, the columns were free-standing. With the above cross-beam in the narrow setting, they connected the 2 towers:

They assured me their measurements were good, but I still requested to drive my truck into position for one final check before we started drilling. They were right... the fit was perfect:

Next it was time to drill 12 anchor bolt holes. These are the massive anchor bolts that get hammered into position. They then crank on the nuts with a large driver and the anchor end part spreads and grabs the concrete. The installer dude said the instructions state to drill the holes just deep enough for the bolts, but he said they always drill completely through the slab. This allows them to hammer the anchor out the bottom (into the dirt) if any of them give them problems. More on that later...

One guy used a large hammer drill while the other sucked-up the dust with my shop vac:

After checking for level, they inserted "U" shaped washers to level-out the columns:

Seriously cranking down on the nuts that hold the lift:

Drilling the other column bolts:

Hammering the anchor bolts into position:

I chose to go with a 2-post lift initially (I have another outlet wired for a possible 4-post lift addition). I went with this lift:

Super-Tall Two-Post Lift - High Rise Lift - XPR-10ASLX

It was their tallest 2-post lift. I'm not sure I'll need the extra height, but since I had the space, I went big. I also wanted the option to be able to lift stuff high enough to transfer to my loft (possibly from the back of my truck)

Now for pictures of the process...

First off, the 3 Cobras got relocated to the house garage:

Once the installers arrived, we discussed options and decided the best option for me was to have the lift installed "backwards." This would allow me to back the vehicles into position vs. driving into the lift forward. The reasons I went with this option were:

1. I normally back all of my vehicles into the garage.

2. The lift motor is on the passenger side tower. Installing it "backwards" more closely aligned it with my 220 prewired power source.

3. By backing the vehicles into position, the mirrors never pass between the towers. This allowed me to use the narrow setting of the lift and still be able to lift my F-150.

4. By installing the lift backwards, it deconflicted with the door on the nearby wall.

Back to the process...

I pulled my truck into position and we mapped out an exact position of the lift:

Since I have foam sprayed walls, the installer measured off the front garage door to find "square."

Next was tackling the monster on the trailer. They expertly used an engine hoist:

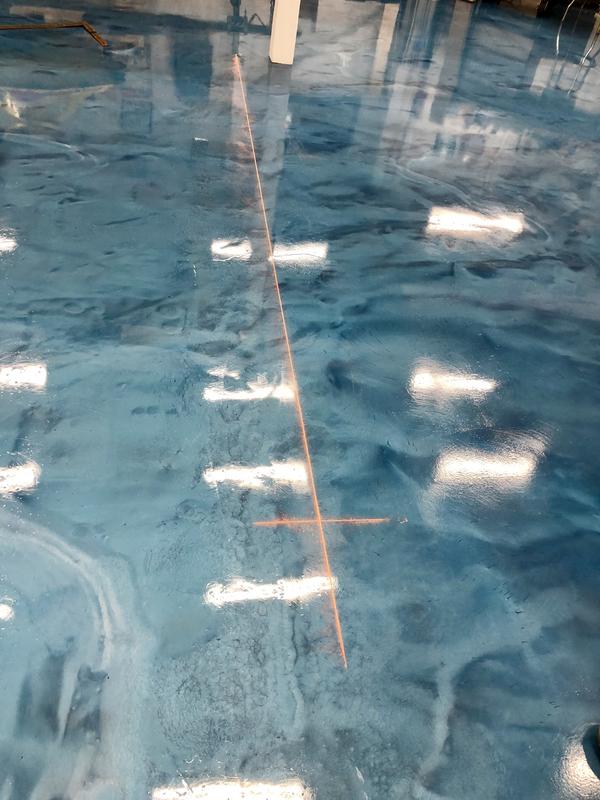

They pushed/pulled the lift into the garage while the heavy tower balanced. Fortunately the nylon wheels didn't mar my floor:

They put down cardboard to protect the floor... winning the battle:

In with the second column/tower:

At this point, the columns were free-standing. With the above cross-beam in the narrow setting, they connected the 2 towers:

They assured me their measurements were good, but I still requested to drive my truck into position for one final check before we started drilling. They were right... the fit was perfect:

Next it was time to drill 12 anchor bolt holes. These are the massive anchor bolts that get hammered into position. They then crank on the nuts with a large driver and the anchor end part spreads and grabs the concrete. The installer dude said the instructions state to drill the holes just deep enough for the bolts, but he said they always drill completely through the slab. This allows them to hammer the anchor out the bottom (into the dirt) if any of them give them problems. More on that later...

One guy used a large hammer drill while the other sucked-up the dust with my shop vac:

After checking for level, they inserted "U" shaped washers to level-out the columns:

Seriously cranking down on the nuts that hold the lift:

Drilling the other column bolts:

Hammering the anchor bolts into position: