Hello,

Just installed the Pedders coilover kit and BMR 5-way adjustable front sway bar on my 2008 GT. Also did a bunch of BMR stuff in the back, but I don't think that will matter here.

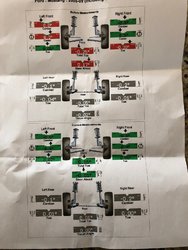

As you can see, the car got aligned really well. But, it is clear to me the driver's side wheel is tucked in more than the right side. Is this going to be a tolerance stack issue with the stock A-arms, K-member, fenders, etc, or is there some adjustments that I can have the alignment shop do?

Far as I know, the car has never been wrecked. I wish it could be handled as easily as the back with the adjustable panhard.

Just installed the Pedders coilover kit and BMR 5-way adjustable front sway bar on my 2008 GT. Also did a bunch of BMR stuff in the back, but I don't think that will matter here.

As you can see, the car got aligned really well. But, it is clear to me the driver's side wheel is tucked in more than the right side. Is this going to be a tolerance stack issue with the stock A-arms, K-member, fenders, etc, or is there some adjustments that I can have the alignment shop do?

Far as I know, the car has never been wrecked. I wish it could be handled as easily as the back with the adjustable panhard.